Method for growing gallium oxide epitaxial layer by adopting halide vapor phase epitaxy method

A technology of vapor phase epitaxy and epitaxial growth, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve the problems of less epitaxial layer reporting and insufficient depth of epitaxial growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

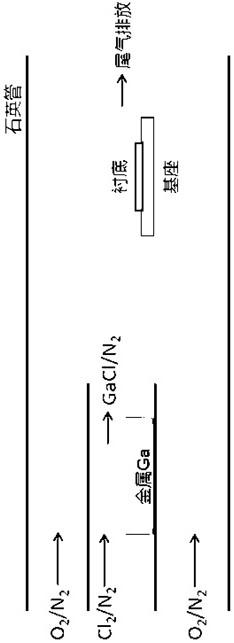

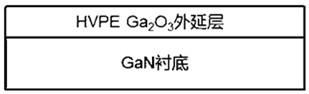

[0025] A method for growing a gallium oxide epitaxial film by halide vapor phase epitaxy, the steps comprising:

[0026] (1) Growth of α-Ga on a GaN single wafer as a substrate 2 o 3 epitaxial layer. Before the start of epitaxial growth, the substrate was heated successively with acetone and absolute ethanol in a water bath at 90°C for 20 minutes, and then ultrasonically cleaned with ultrapure water for 10 minutes to remove organic and inorganic impurities on the surface.

[0027] (2) Place the substrate sheet in (1) under a differential interference microscope to observe its appearance, and confirm that the surface of the substrate sheet is clean and smooth, free of paraffin wax, attached particles, scratches, and damage.

[0028] (3) Put the substrate sheet in (2) horizontally on the base, and send it to the growth temperature zone of the halide vapor phase epitaxy tube furnace.

[0029] (4) Close the horizontal tube furnace, extract the vacuum for 20 minutes, and repeate...

Embodiment 2

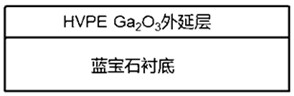

[0035] A method for growing a gallium oxide epitaxial film by halide vapor phase epitaxy, the steps comprising:

[0036] (1) Growth of β-Ga on sapphire substrate 2 o 3 epitaxial layer. Before the start of epitaxial growth, the substrate was heated successively with acetone and absolute ethanol in a water bath at 90°C for 20 minutes, and then ultrasonically cleaned with ultrapure water for 10 minutes to remove organic and inorganic impurities on the surface.

[0037] (2) Place the substrate sheet in (1) under a differential interference microscope to observe its appearance, and confirm that the surface of the substrate sheet is clean and smooth, free of paraffin wax, attached particles, scratches, and damage.

[0038] (3) Put the substrate sheet in (2) horizontally on the base, and send it to the growth temperature zone of the halide vapor phase epitaxy tube furnace.

[0039] (4) Close the horizontal tube furnace, extract the vacuum for 20 minutes, and repeatedly flush the c...

Embodiment 3

[0045] A method for growing a gallium oxide epitaxial film by halide vapor phase epitaxy, the steps comprising:

[0046] (1) With β-Ga 2 o 3 Homogeneous growth of β-Ga on single crystal as substrate 2 o 3 epitaxial layer. Before the start of epitaxial growth, the substrate was heated successively with acetone and absolute ethanol in a water bath at 90°C for 20 minutes, and then ultrasonically cleaned with ultrapure water for 10 minutes to remove organic and inorganic impurities on the surface.

[0047] (2) Place the substrate sheet in (1) under a differential interference microscope to observe its appearance, and confirm that the surface of the substrate sheet is clean and smooth, free of paraffin wax, attached particles, scratches, and damage.

[0048] (3) Put the substrate sheet in (2) horizontally on the base, and send it to the growth temperature zone of the halide vapor phase epitaxy tube furnace.

[0049] (4) Close the horizontal tube furnace, extract the vacuum for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com