Antibacterial fiber loaded with metal organic framework nano enzyme and glucose as well as preparation method and application of antibacterial fiber

A metal-organic framework and organic framework technology, applied in fiber type, fiber treatment, animal fiber, etc., can solve the problems of low cascade reaction activity, limit the practical application of infected wounds, etc., and achieve the effect of high-efficiency antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

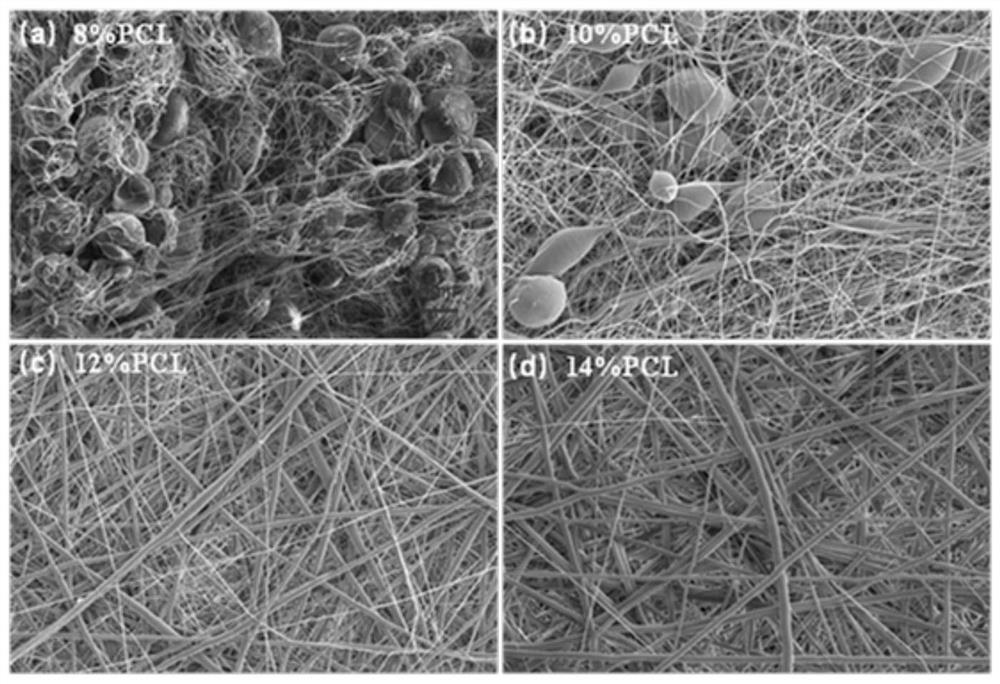

[0049] The preparation of embodiment 1 polycaprolactone electrospun fiber membrane

[0050] Weigh 1.2g, 1.5g, 1.8g, and 2.1g of PCL (average molecular weight: 80,000) pellets and add them into 15mL of 2,2,2-trifluoroethanol, and stir at room temperature for 12 hours to obtain 8%, 10%, 12%, and 14 %PCL transparent spinning solution.

[0051] Since the solution concentration, electrospinning rate, voltage, receiving distance and humidity temperature will all affect the morphology of the fiber, it is necessary to prepare uniform and continuous fibers under the condition that the electrospinning solution is stable and the electrospinning process is carried out smoothly. One of the key issues of silk. After adjusting the external factors affecting spinning and other factors, the optimal spinning conditions were obtained: the spinning concentration was 14%, the voltage was 10kV, the receiving distance was 15cm, and the advancing rate was 2.0mL / h. Use a 10mL disposable syringe to e...

Embodiment 2

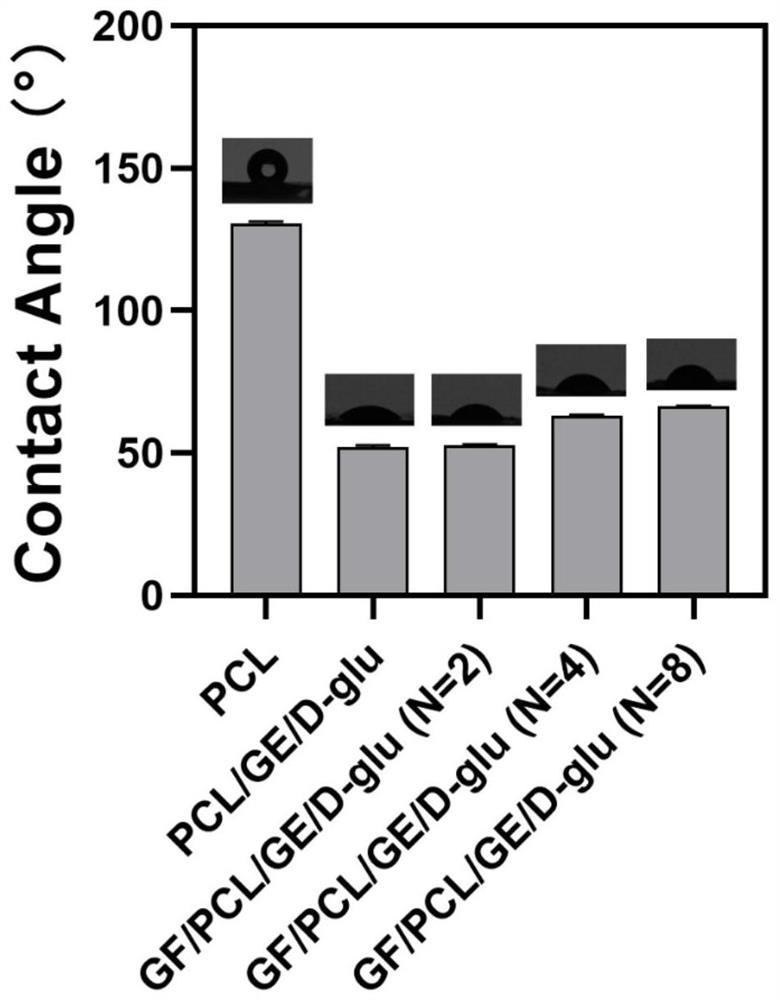

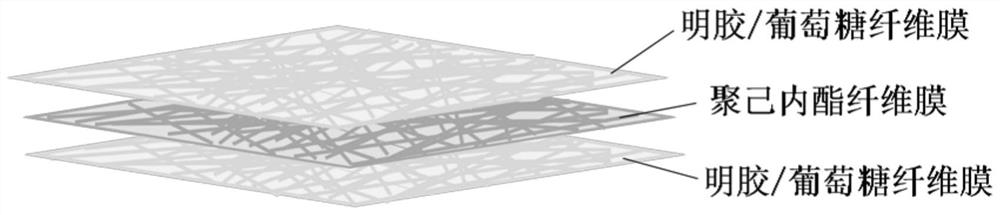

[0053] Example 2 Preparation of electrospun fiber membrane with polycaprolactone / gelatin / glucose sandwich multilayer structure

[0054] Weigh 1.0g of glucose and dissolve it in 1mL of deionized water at high temperature, continue to add 9mL of glacial acetic acid, stir well; add 5mL of 2,2,2-trifluoroethanol, mix well; add 1.5g of gelatin (glue strength is about 250gBloom), Stirring was continued for 2 hours to obtain a uniform 10%GE / 6.7%D-glu spinning solution. In addition, 2.1 g of PCL (average molecular weight: 80,000) was dissolved in 15 mL of 2,2,2-trifluoroethanol, and stirred evenly at room temperature overnight to obtain a uniform 14% PCL spinning solution.

[0055] Firstly, 1mL of GE / D-glu spinning solution was drawn out with a 10mL disposable syringe and placed on a syringe pump. Electrospinning was carried out by using a 21-gauge flat needle and adjusting the distance and voltage between the needle and the receiving plate. Spinning conditions: the voltage is 20kV, ...

Embodiment 3

[0057] The preparation of embodiment 3 polycaprolactone / gelatin / glucose blended fiber membrane (PCL / GE / D-glu)

[0058] Weigh 1.0g of glucose and dissolve it in 1mL of deionized water at high temperature; continue to add 9mL of glacial acetic acid and stir well; add 5mL of 2,2,2-trifluoroethanol and mix well; finally add 2.1g of polycaprolactone and 1.5g of gelatin (glue strength is about 250gBloom), continue to stir for 2h, obtain uniform yellow transparent solution, as Figure 4 shown. The solvent ratio (water / glacial acetic acid / 2,2,2-trifluoroethanol) in the final spinning solution is 1:9:5, and the solute fraction (polycaprolactone / gelatin / glucose) is 14%PCL / 10%GE / 6.7% D-glu.

[0059] Use a 10mL disposable syringe to extract 4mL of spinning solution and put it on a syringe pump. Use a No. 21 flat needle and adjust the distance and voltage between the needle and the receiving plate to carry out electrospinning. Spinning conditions: the voltage is 18kV, the receiving dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com