Preparation method of lignin carbon film for adsorbing H2S

A technology of lignin and alkali lignin, which is applied in the field of preparation of deodorizing materials, can solve the problems of inability to serve as a structural support, brittle carbon film, and brittleness, etc., and achieves good deodorization effect, sufficient raw materials, and little environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of lignin carbon film is characterized in that: preparation of alkali lignin carbon film, preparation of film-making liquid and solution casting film-forming process are composed of the following steps:

[0033] Step 1: put the alkali lignin into a tubular resistance furnace, and carbonize the alkali lignin under the protection of nitrogen. The heating rate of the resistance furnace is 5°C / min-8°C / min, and the carbonization temperature is 350°C-400°C , the carbonization time is 90min to 100min, and the carbonized material is cooled under the nitrogen protection at 5°C / min, cooled to room temperature and removed from the tubular resistance furnace to obtain alkali lignin charcoal;

[0034] Step 2, preparing a polyvinyl alcohol aqueous solution with a mass concentration of 3.0% to 5.0%, mixing alkali lignin charcoal, polyvinyl alcohol aqueous solution, and water according to the solid-to-liquid ratio (g:mL:mL) 3:50:50 to 5: Mix and stir at 50:150 for ...

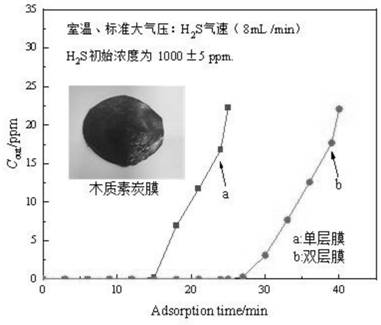

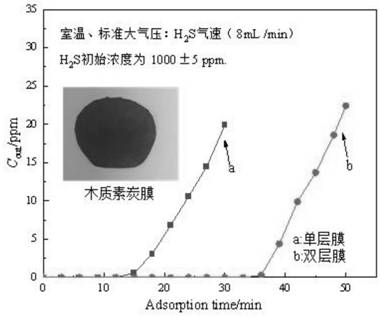

example 1

[0039] Put 1g of alkali lignin in a magnetic boat, put it into a tube-type resistance furnace, and carry out carbonization treatment on alkali lignin under the protection of nitrogen. After 100 min, the carbonized material was cooled under nitrogen protection at 5°C / min, cooled to room temperature and removed from the tubular resistance furnace to obtain alkali lignin charcoal; a polyvinyl alcohol aqueous solution with a mass concentration of 5.0% was prepared; 0.3 g of alkali Put lignin charcoal, 5mL 5% polyvinyl alcohol aqueous solution and 15mL water into a beaker, mix and stir for 4 hours, then add 0.1mL glycerin and continue stirring for 2 hours, and obtain the film-forming solution after the stirring; quickly pour the film-forming solution into 9 In a plastic petri dish of ×9cm, let it stand for 2 hours for defoaming. After defoaming, place it in a vacuum drying oven for drying at 70°C for 6 hours. The lignin carbon film was peeled off from the dish to obtain a lignin ca...

example 2

[0042]Put 1g of alkali lignin in a magnetic boat, put it into a tubular resistance furnace, and carry out carbonization treatment on alkali lignin under the protection of nitrogen. The heating rate is 5°C / min, the carbonization temperature is 400°C, and the carbonization time is 95min. After carbonization, the material was cooled under a nitrogen protection program at 5°C / min, cooled to room temperature and removed from a tubular resistance furnace to obtain alkali lignin charcoal; a polyvinyl alcohol aqueous solution with a mass concentration of 5.0% was prepared; 0.4g alkali lignin Put charcoal, 5mL of 5% polyvinyl alcohol aqueous solution and 10mL water into a beaker, mix and stir for 4 hours, then add 0.15mL glycerin and continue to stir for 2 hours, and obtain the film-forming solution after stirring; quickly pour the film-forming solution into 9× In a 9cm plastic petri dish, let it stand for 2 hours for defoaming. After defoaming, put it in a vacuum drying oven for drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com