Repairing agent and repairing method for surface damage of silicon carbide ceramic matrix composite material

A technology of silicon carbide ceramic matrix and composite materials, which is applied in the repair agent and field of surface damage of silicon carbide ceramic matrix composite materials, can solve the problems of poor processability, long cycle, and difficult surface repair, and achieve high temperature resistance and combination High strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

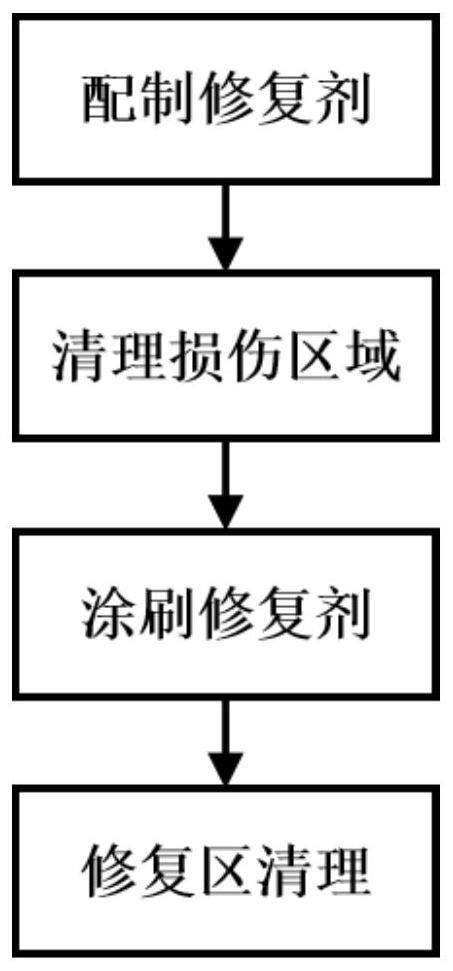

Method used

Image

Examples

Embodiment 2

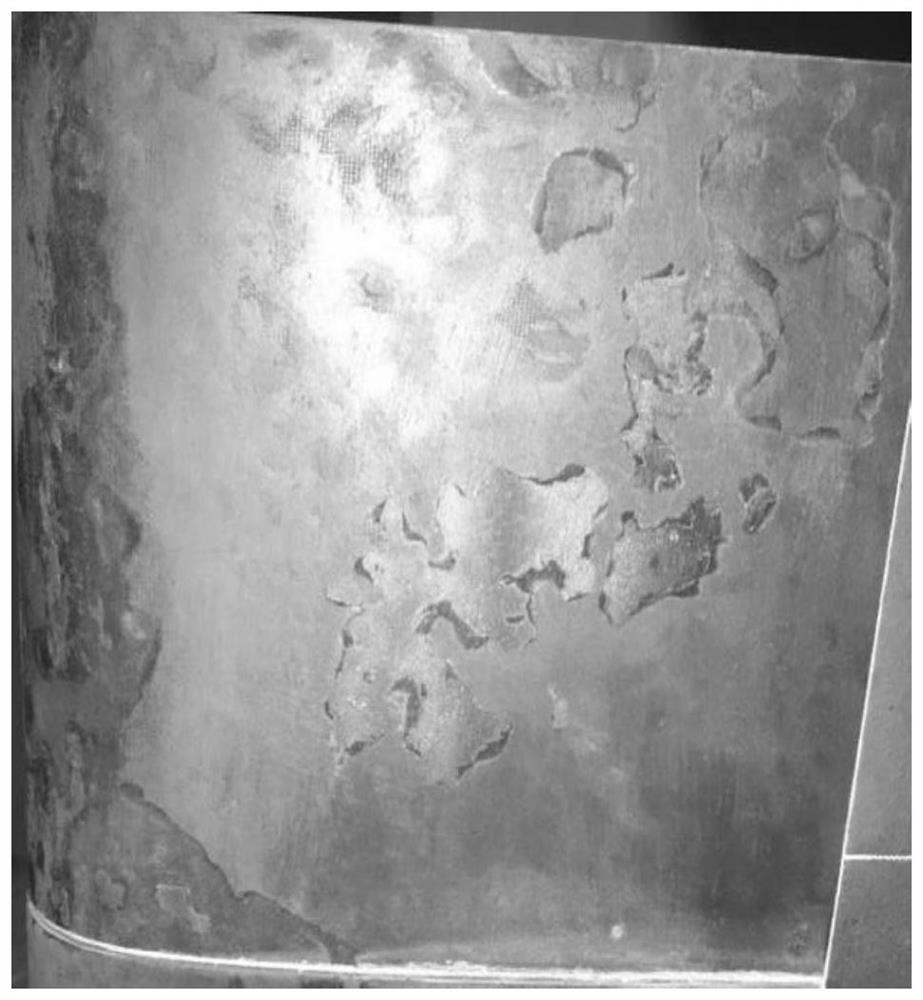

[0031] The surface area of a continuous carbon fiber reinforced silicon carbide ceramic matrix composite component is about 80×50mm 2 The surface coating falls off, and the maximum damage depth is about 0.15mm. The repair steps are as follows:

[0032] Step 1: Prepare the restorative. Adopt balance to weigh solid polycarbosilane, xylene, zirconium carbide powder, silicon carbide powder and silicon carbide whisker respectively, and its mass ratio is 1:1.6:0.5:1.2:0.02; Solid polycarbosilane, xylene, carbonized Put zirconium powder, silicon carbide powder, silicon carbide whiskers and zirconia ball milling beads with a diameter of 8 mm into a sealed ball milling tank, and ball mill at a speed of 80 rpm for 10 hours; take out the milled material liquid into a reagent bottle , and use a magnetic stirrer to continuously stir at a speed of 100 rpm for use.

[0033] Step 2: Clean up the damaged area. Use a diamond file to polish the damaged area of the component to ensure tha...

Embodiment 3

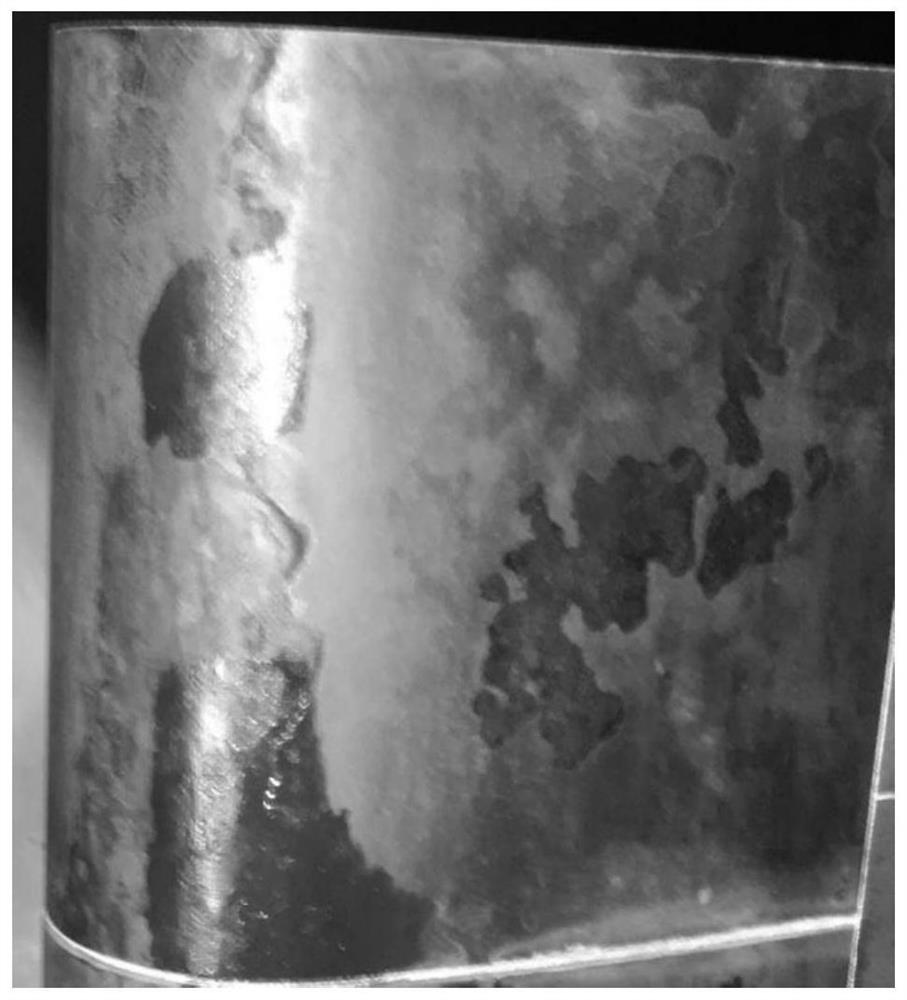

[0037] The surface area of a continuous silicon carbide fiber reinforced silicon carbide ceramic matrix composite component is about 20×20mm 2 The surface coating peeled off, and the maximum damage depth was about 0.3mm. The repair steps are as follows:

[0038] Step 1: Prepare the restorative. Adopt balance to weigh solid polycarbosilane, xylene, zirconium carbide powder, silicon carbide powder and silicon carbide whisker respectively, and its mass ratio is 1:1.5:0.3:1.5:0.12; Solid polycarbosilane, xylene, carbonized Put zirconium powder, silicon carbide powder, silicon carbide whiskers, and zirconia ball milling beads with a diameter of 8 mm into a sealed ball milling tank, and ball mill at a speed of 120 rpm for 20 hours; take out the milled material liquid into a reagent bottle , and use a magnetic stirrer to continuously stir at a speed of 120 rpm for use.

[0039] Step 2: Clean up the damaged area. Use a diamond file to polish the damaged area of the component t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com