Compound for packaging film, ink composition containing same and film packaging structure

A technique for ink composition and encapsulation film, which is applied in the fields of ink composition and film encapsulation structure containing it, and compound for encapsulation film, which can solve problems such as adverse effects of devices, decrease of flatness of inorganic film, increase of WVTR, etc., and achieve good durability Thermal performance, improved reliability, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a thin film encapsulation structure, comprising the following steps:

[0048] Step S1: Treatment of organic layer materials

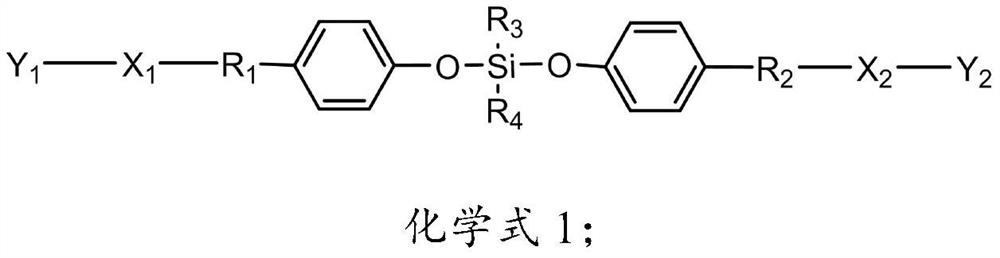

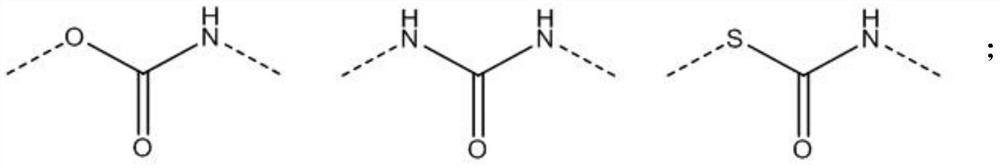

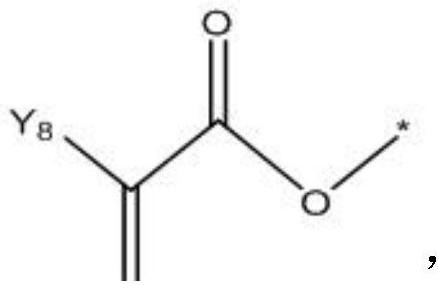

[0049] Among them, the compound for packaging film (chemical formula 001), acrylic acid monomer (2-((naphthalene-2-yloxy)methoxy)ethyl (meth)acrylic acid), photoinitiator (2-methyl-1 -(4-(methylthio)phenyl)-2-morpholinopropan-1-one);

[0050]

[0051] Weigh 25g of 001, 70g of 2-((naphthalene-2-yloxy)methoxy)ethyl (meth)acrylic acid and 5g of 2-methyl-1-(4-(methylthio)benzene Base)-2-morpholinopropan-1-one, mixed together, stirred under vacuum at 50°C for 80h, then filtered with a syringe filter, and detected with a particle counter, when the particle size was detected to be greater than 0.5μm When the number of particles is not more than 50, the organic layer material is obtained;

[0052] Step S2: Preparation of Inorganic Layer

[0053] Silicon nitride is selected as the inorganic layer material, and the inorganic l...

Embodiment 2

[0059] The preparation method of thin-film encapsulation structure differs from Example 1 in that 25g of compound for encapsulation film (chemical formula 002), 70g of acrylic acid monomer (10-phenoxydecyl (meth)acrylic acid), 5g of photoinitiator (2-Benzyl-2-dimethylamino-1-(4-morpholinophenyl)-butydan-1-one);

Embodiment 3

[0061]

[0062] The difference between the preparation method of the thin film encapsulation structure and that of Example 1 is that

[0063] Among them, 25g compound for packaging film (chemical formula 003), 70g acrylic acid monomer (2-((phenylthio)methoxy)ethyl (meth)acrylic acid), 5g photoinitiator (2-hydroxy-2-methyl base acetophenone);

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com