Crosslinked polyethylene composite material as well as preparation method and application thereof

A technology for cross-linked polyethylene and composite materials, applied in the field of cross-linked polyethylene composite materials and their preparation, can solve the problems of affecting electrical properties, mechanical properties and thermal stability, shorten the service life of cables, etc. Breakdown ability, the effect of improving the operating voltage of the AC cable material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

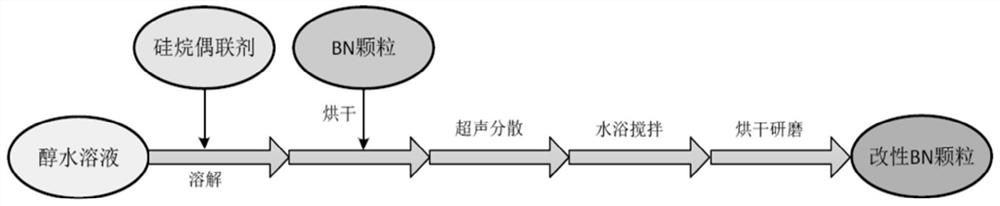

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a cross-linked polyethylene composite material, comprising the following components in parts by mass: 100 parts of low-density polyethylene, 1.8 parts of dicumyl peroxide, 0.4 parts of triallyl cyanurate, 0.2 parts of antioxidant 1010, 3 parts of nanometer vinyl cage polysilsesquioxane and 30 parts of boron nitride; Boron nitride composition, the mass ratio of boron nitride with a particle size of micron and boron nitride with a particle size of nanometer is 3:1.

[0033] Wherein boron nitride is hexagonal boron nitride, and the average median particle diameter of micron-scale boron nitride is 10 μm; the average median particle diameter of nanometer-scale boron nitride is 50 nm. The purity is 99.1%; the density of low-density polyethylene is 0.9210g / cm 3 , The melt flow rate is 1.5g / 10min, the gel content is 86%; the melting point of nano vinyl cage polysilsesquioxane is 360°C, and the flash point is 210°C.

[0034] This embodiment also provid...

Embodiment 2

[0039] This embodiment provides a cross-linked polyethylene composite material, comprising the following components by mass: 100 parts of low-density polyethylene, 1.9 parts of ethylene peroxide, 0.3 parts of triallyl isocyanurate, 0.25 parts Parts of antioxidant 1035, 2 parts of nano vinyl cage polysilsesquioxane and 35 parts of boron nitride; The composition of boron, the mass ratio of boron nitride with a particle size of micron and boron nitride with a particle size of nanometer is 4:1.

[0040] Wherein boron nitride is hexagonal boron nitride, and the average median particle diameter of micrometer-sized boron nitride is 5 μm; the average median particle diameter of nanometer-sized boron nitride is 40 nm, The purity is 99.1%; the density of low-density polyethylene is 0.9220g / cm 3 , The melt flow rate is 0.9g / 10min, the gel content is 84%; the melting point of nano vinyl cage polysilsesquioxane is 355°C, and the flash point is 205°C.

[0041] This embodiment also provide...

Embodiment 3

[0046] This embodiment provides a cross-linked polyethylene composite material, comprising the following components in parts by mass: 100 parts of low-density polyethylene, 2 parts of dicumyl peroxide, 0.5 part of trimethylolpropane trimethacrylate , 0.3 parts of antioxidant 300, 4 parts of nano vinyl cage polysilsesquioxane and 40 parts of boron nitride; The composition of boron nitride, the mass ratio of boron nitride with a particle size of micron and boron nitride with a particle size of nanometer is 6:1.

[0047] Wherein boron nitride is hexagonal boron nitride, and the average median particle diameter of micron-scale boron nitride is 15 μm; the average median particle diameter of nanometer-scale boron nitride is 60 nm. The purity is 99.1%; the density of low-density polyethylene is 0.9230g / cm 3 , The melt flow rate is 2.1g / 10min, the gel content is 82%; the melting point of nano vinyl cage polysilsesquioxane is 350°C, and the flash point is 200°C.

[0048] This embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com