Alcohol production process with high liquor yield

A production process and alcohol technology, applied in the field of alcohol, can solve the problems of low production efficiency, high cost, and backwardness, and achieve the effects of complete fermentation, low residual sugar, and improved fermentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

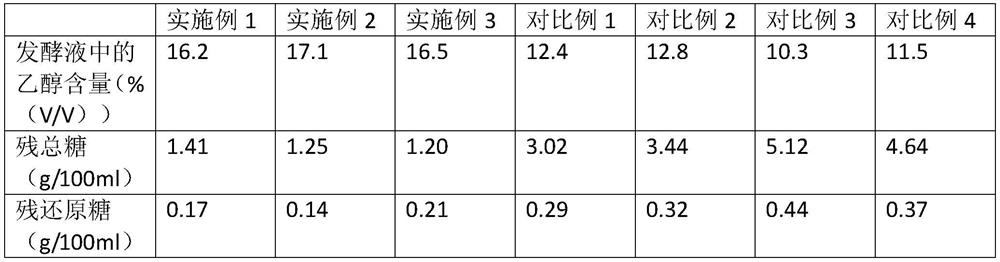

Examples

Embodiment 1

[0026] A kind of alcohol production technique of high liquor yield, wherein: comprise the following steps:

[0027] S1. Grinding the dried sweet potato with skin into sweet potato starch, passing through a sieve of 40 to 60 mesh, using the oversize and undersize together as raw materials for making a slurry, and then mixing with water to form a slurry with a concentration of 40wt%;

[0028] S2. Add amylase to the slurry, the amount of amylase is 12u / g, and a stabilizer is added, the stabilizer is calcium hydrogen phosphate and L-arginine, and the addition of calcium hydrogen phosphate is the total mass of the slurry 0.05%, the added amount of L-arginine is 0.01% of the total mass of the powder slurry, and then liquefaction treatment is carried out at 85°C-105°C, and the liquefaction time is 120min to obtain the liquefaction slurry;

[0029] S3. Add glucoamylase and xylanase to the liquefied slurry, the amount of glucoamylase and xylanase added is 150 U / g, and carry out sacchar...

Embodiment 2

[0032] A kind of alcohol production technique of high liquor yield, wherein: comprise the following steps:

[0033] S1. Grinding the dried sweet potato with skin into sweet potato starch, and passing through a sieve of 40 to 60 meshes, using the sieve and the undersize together as raw materials for making a slurry, and then mixing it with water to form a 42wt% slurry;

[0034] S2. Add amylase to the slurry, the amount of amylase is 15u / g, and a stabilizer is added, the stabilizer is calcium hydrogen phosphate and L-arginine, and the addition of calcium hydrogen phosphate is the total mass of the slurry 0.06% of the total mass of the L-arginine, the added amount of L-arginine is 0.2% of the total mass of the slurry, and then liquefied at 95°C for 60 minutes to obtain the liquefied slurry;

[0035] S3. Add glucoamylase and xylanase to the liquefied slurry, the addition amount of glucoamylase and xylanase are both 200U / g, carry out saccharification treatment at 55°C, the sacchari...

Embodiment 3

[0038] A kind of alcohol production technique of high liquor yield, wherein: comprise the following steps:

[0039] S1. Grinding the dry sweet potato with skin into sweet potato starch, and passing through a 40-60 mesh screen, using the oversize and undersize together as raw materials for making a slurry, and then mixing it with water to form a 46wt% slurry;

[0040] S2. Add 18u / g amylase to the slurry, and add a stabilizer, the stabilizer is calcium hydrogen phosphate and L-arginine, the addition of calcium hydrogen phosphate is 0.1% of the total mass of the slurry, and the L - The amount of arginine added is 0.5% of the total mass of the slurry, and then liquefied at 105°C for 30 minutes to obtain a liquefied slurry;

[0041] S3. Adding glucoamylase and xylanase to the liquefied slurry, the amounts of both glucoamylase and xylanase are 250 U / g, and performing saccharification at 60° C. for 25 minutes to obtain saccharified slurry;

[0042] S4. Add 0.8ml / g yeast material, 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com