Hydrogen sensor core, preparation method thereof and hydrogen sensor

A sensor core and sensor technology, used in instruments, scientific instruments, electrochemical variables of materials, etc., can solve problems such as complex preparation processes, and achieve the effects of low detection limit, high sensitivity and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

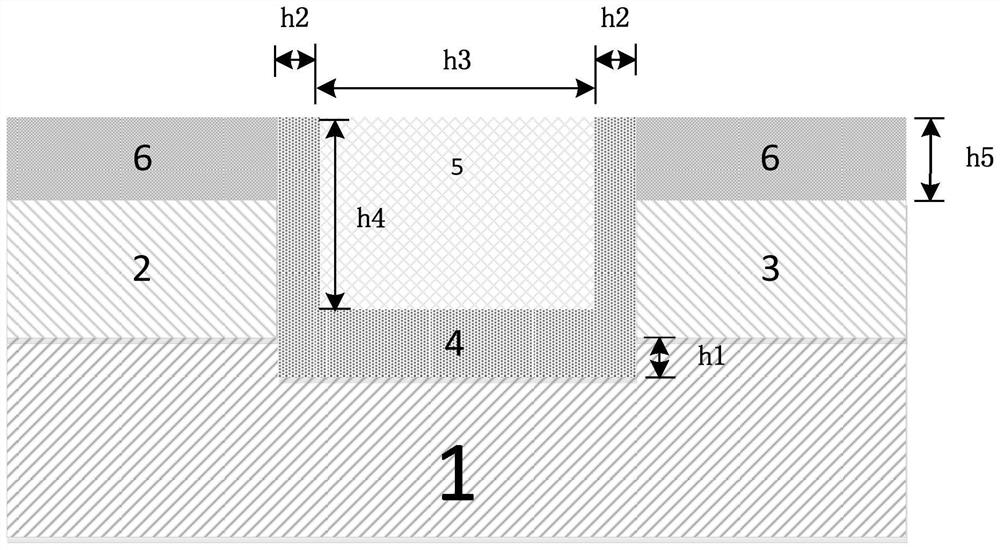

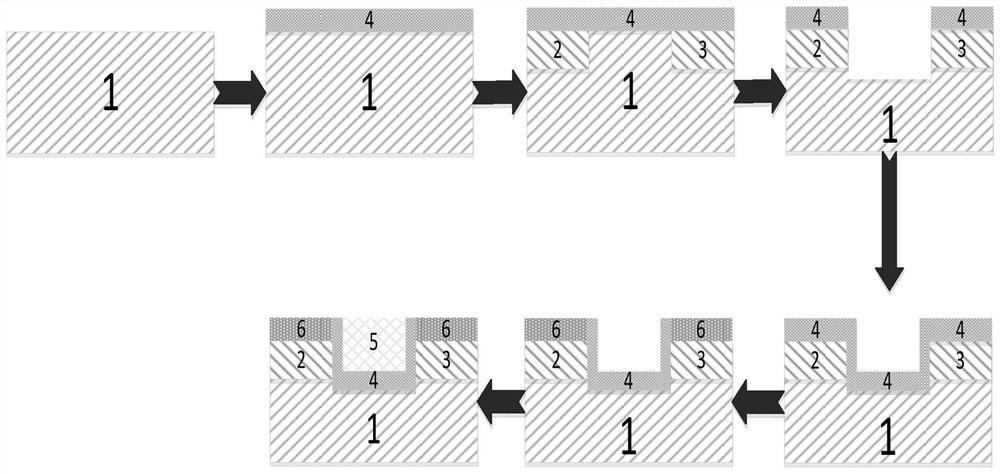

[0054] like figure 1 As shown, the hydrogen sensor core body of the present embodiment includes:

[0055] semiconductor substrate 1;

[0056] A source 2 and a drain 3 formed on the semiconductor substrate 1;

[0057] a trench region formed on the surface of the semiconductor substrate 1 between the source 2 and the drain 3;

[0058] The dielectric layer 4 formed on the groove area, the thickness (h2) of the dielectric layer 4 positioned on the side of the groove area is 5nm;

[0059] The hydrogen sensitive layer 5 formed on the dielectric layer 4 uses the hydrogen sensitive layer 5 as a gate, wherein the width (h3) of the gate is 20nm, and the negative junction depth (h1) of the gate is 10nm;

[0060] A metal electrode layer 6 formed on the hydrogen sensitive layer 5 .

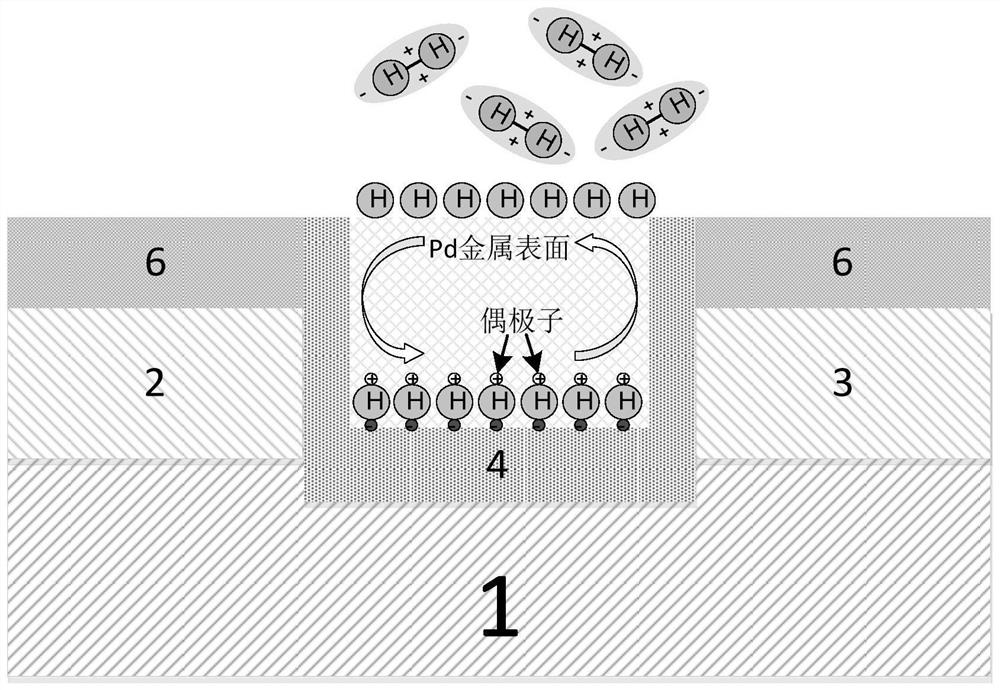

[0061] like figure 2 As shown, in the present invention, after hydrogen is adsorbed on the surface of the palladium or palladium alloy hydrogen sensitive layer, under its catalytic action, the hydrogen m...

Embodiment 2

[0076] like figure 1 As shown, the hydrogen sensor core body of the present embodiment includes:

[0077] semiconductor substrate 1;

[0078] A source 2 and a drain 3 formed on the semiconductor substrate 1;

[0079] a trench region formed on the surface of the semiconductor substrate 1 between the source 2 and the drain 3;

[0080] The dielectric layer 4 formed on the groove area, the thickness of the dielectric layer 4 located on the side of the groove area is 7nm;

[0081] The hydrogen sensitive layer 5 formed on the dielectric layer 4 uses the hydrogen sensitive layer 5 as a gate, wherein the width of the gate is 20nm, and the negative junction depth of the gate is 11nm;

[0082] A metal electrode layer 6 formed on the hydrogen sensitive layer 5 .

[0083] In this embodiment, the semiconductor substrate 1 is a P-type single wafer, and the doping concentration of boron is 2.2×10 17 cm -3 .

[0084] In this embodiment, the doping concentration of phosphorus in the sou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com