Flexible metal organic framework-based plastic crystal electrolyte as well as preparation method and application thereof

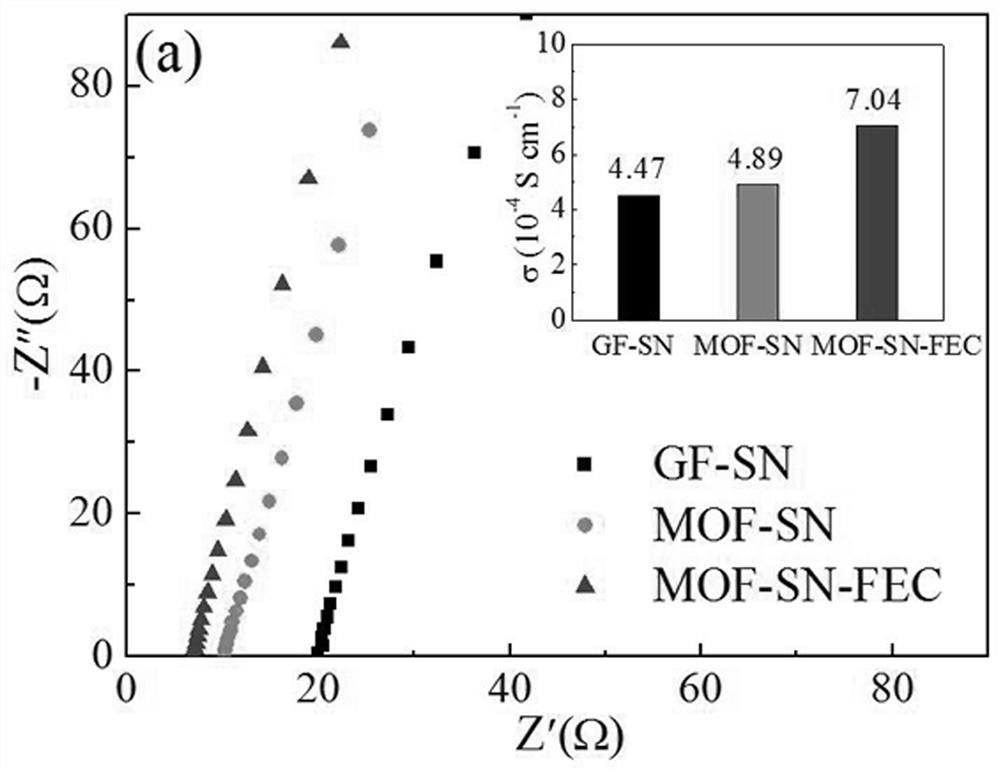

A metal-organic framework and organic framework technology, applied in the manufacture of electrolyte batteries, composite electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of uneven distribution of MOF particles, low lithium ion migration number, large interfacial gap, etc., and achieve good flexibility , Promote uniform distribution and avoid the effect of large interfacial gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the flexible metal-organic framework-based plastic crystal electrolyte in this embodiment, the steps are as follows:

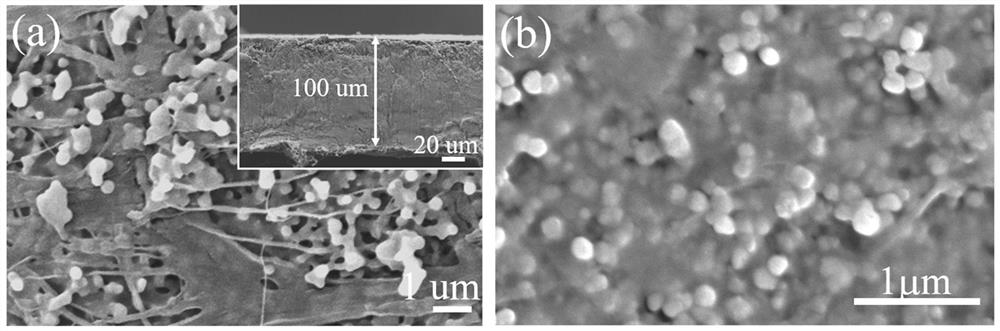

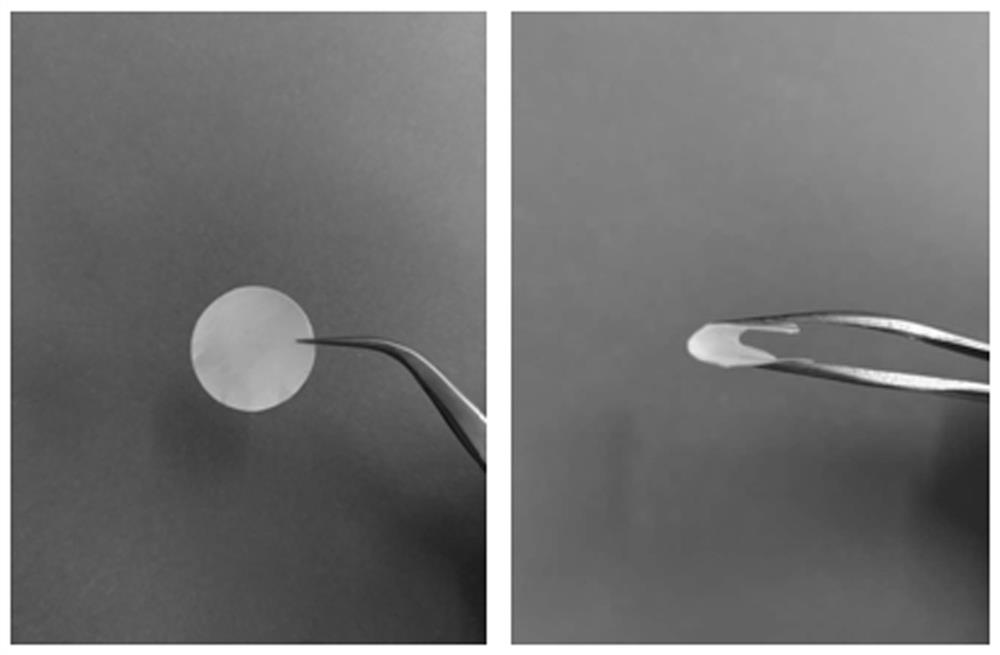

[0034] (1) Preparation of metal-organic framework (MOF) film: Zn(NO 3 ) 2 .6H 2 O and 2-methylimidazole were added to 100 mL of methanol, and after fully dissolved, the methanol solution containing 2-methylimidazole was slowly dropped into the solution containing Zn(NO 3 ) 2 .6H 2 O in methanol solution, stirred thoroughly for 2 hours. Then stand at room temperature for 24 hours, then centrifuge at 8000 rpm, and wash thoroughly with methanol solution three times. Then the above-mentioned substances were placed in a vacuum drying oven at 60° C., and were taken out for grinding after 12 hours. The above metal organic framework material and PTFE were fully mixed at a molar ratio of 9:1, and then a MOF film with a thickness of 100 μm was made by rolling method, and punched into a disc with a diameter of 16 mm.

[0035] (2) P...

Embodiment 2

[0041] The preparation method of the flexible metal-organic framework-based plastic crystal electrolyte in this example is the same as in Example 1, except that step (1) is changed to: prepare MOF film: Co(NO 3 ) 2 .6H 2 O and 2-methylimidazole were added to 100 mL of methanol, and after fully dissolved, the methanol solution containing 2-methylimidazole was slowly dropped into the solution containing Zn(NO 3 ) 2 .6H 2 O in methanol solution, stirred thoroughly for 2 hours. Then stand at room temperature for 24 hours, then centrifuge at 8000 rpm, and wash thoroughly with methanol solution three times. Then the above-mentioned substances were placed in a vacuum drying oven at 60° C., and were taken out for grinding after 12 hours. The above metal organic framework material and PTFE were fully mixed at a molar ratio of 9:1, and then a film with a thickness of 100 μm was made by rolling method, and punched into a disc with a diameter of 16 mm.

Embodiment 3

[0043] The preparation method of the flexible metal-organic framework-based plastic crystal electrolyte in this embodiment, the steps are as follows:

[0044] (1) Preparation of MOF membrane: Zn(NO 3 ) 2 .6H 2 O and 2-methylimidazole were added to 100 mL of methanol, and after fully dissolved, the methanol solution containing 2-methylimidazole was slowly dropped into the solution containing Zn(NO 3 ) 2 .6H 2 O in methanol solution, stirred thoroughly for 2 hours. Then stand at room temperature for 24 hours, then centrifuge at 8000 rpm, and wash thoroughly with methanol solution three times. Then the above-mentioned substances were placed in a vacuum drying oven at 60° C., and were taken out for grinding after 12 hours. The above metal organic framework material and PTFE were fully mixed at a molar ratio of 9:1, and then a MOF film with a thickness of 50 μm was made by rolling method, and punched into a disc with a diameter of 16 mm.

[0045] (2) Preparation of plastic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com