Desonide cream and preparation method thereof

A technology of desonide and cream, applied in the field of medicine, can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

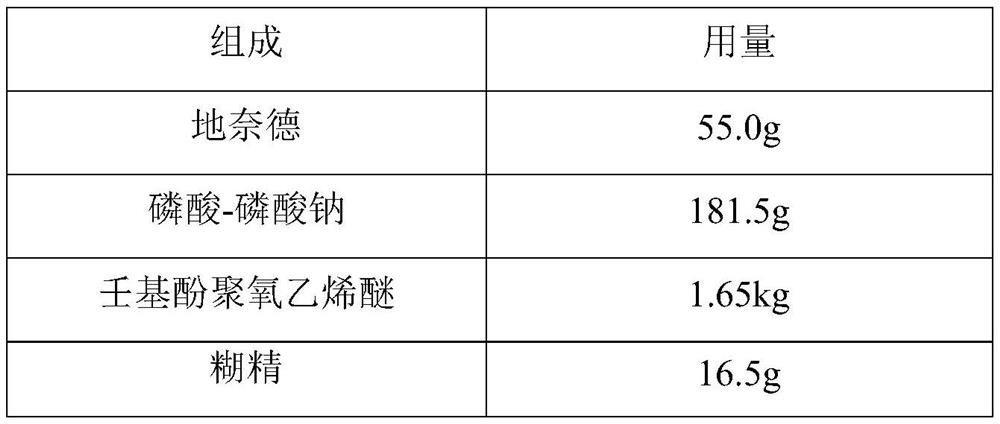

Embodiment 1

[0024]

[0025]

[0026] Preparation:

[0027] 1) Preparation of the water phase: heat the purified water to 70°C to 75°C, add buffered p-phosphate-sodium phosphate buffer pair (pH=5), dextrin, nonylphenol polyoxyethylene ether and methylparaben and stir to mix Evenly, keep warm for later use;

[0028] 2) Preparation of the oil phase: heating the oil base, including light liquid paraffin, cetostearyl alcohol, white petrolatum, and beeswax to melt to obtain the oil phase material, and keeping it warm at 70°C to 75°C for later use;

[0029] 3) Preparation of main drug dispersion: disperse desonide in glycerin to obtain main drug dispersion suspension;

[0030] 4) Total mixing: the oil phase material and the water phase material are mixed evenly, and the dispersion suspension of the main ingredient is added;

[0031] 5) Cooling: Mix evenly and cool to room temperature to obtain desonide cream.

Embodiment 2

[0033] composition Dosage Desonide 55.0g Citric Acid-Sodium Citrate 110.0g Castor oil polyoxyethylene ether 1.1kg dextrin 22.0g Methylparaben 110.0g glycerin 4.40kg cetostearyl alcohol 13.2kg White Vaseline 16.5kg purified water 74.5kg total 110kg

[0034] Preparation:

[0035] 1) Preparation of water phase: heat purified water to 70°C-75°C, add buffered p-citric acid-sodium citrate buffer pair (pH=5.5), dextrin, castor oil polyoxyethylene ether and paraben Stir the ester to mix well and keep warm for later use;

[0036] 2) Preparation of the oil phase: heat up the oil base, including cetostearyl alcohol and white petrolatum, to melt to obtain the oil phase material, and keep it warm at 70°C to 75°C for later use;

[0037] 3) Preparation of main drug dispersion: disperse desonide in glycerin to obtain main drug dispersion suspension;

[0038] 4) Total mixing: the oil phase material and the water...

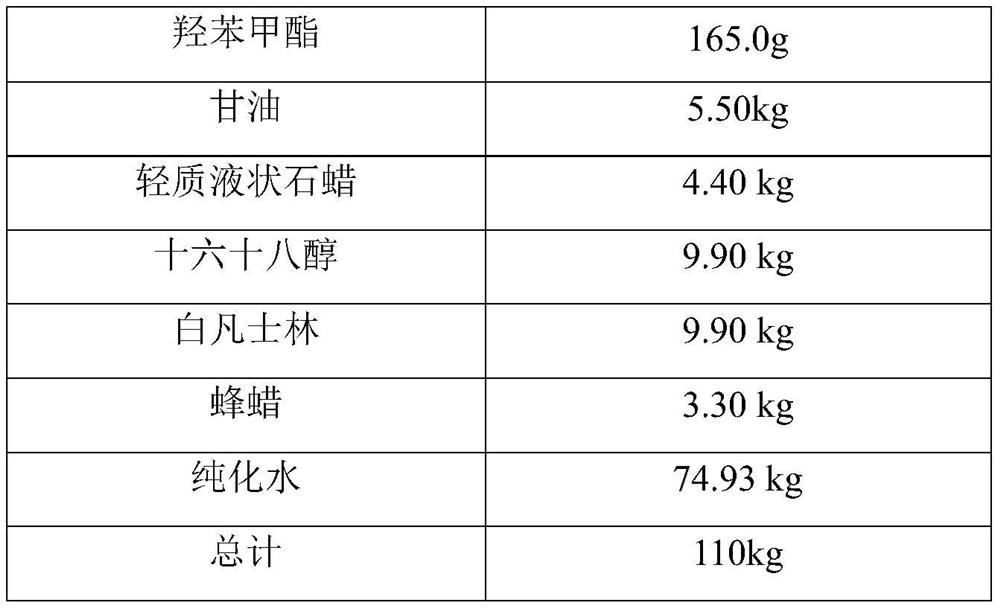

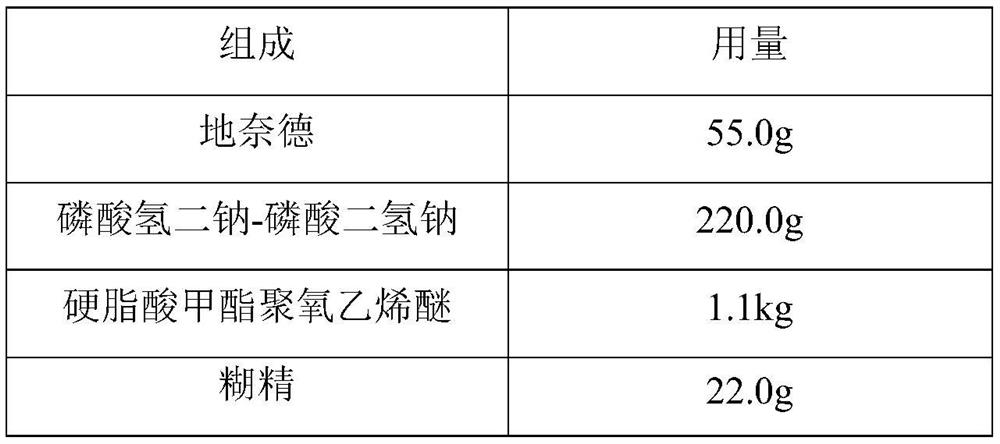

Embodiment 3

[0041] composition Dosage Desonide 55.0g Citric Acid-Disodium Hydrogen Phosphate 220.0g Oleyl alcohol polyoxyethylene ether 1.1kg Octylphenol polyoxyethylene ether 1.1kg dextrin 11.0g Methylparaben 220.0g glycerin 6.60kg light liquid paraffin 2.2kg cetostearyl alcohol 16.5kg White Vaseline 13.2kg beeswax 6.6kg purified water 62.2kg total 110kg

[0042] Preparation:

[0043] 1) Preparation of water phase: heat purified water to 70°C to 75°C, add buffered pcitric acid-disodium hydrogen phosphate buffered pair (pH=4.5), dextrin, oleyl alcohol polyoxyethylene ether, octylphenol Polyoxyethylene ether and methylparaben are stirred and mixed, and kept warm for subsequent use;

[0044] 2) Preparation of the oil phase: heating the oil base, including light liquid paraffin, cetostearyl alcohol, white petrolatum, and beeswax to melt to obtain the oil phase material, and keeping it warm a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com