Preparation method of high-strength light-weight flange forging part of automobile air conditioner

A technology for automobile air conditioners and forged parts is applied in the field of preparation of automobile air conditioner flange forgings, which can solve the problems of easy cracking and air leakage, high production cost, low material strength, etc., so as to improve product life, improve product performance, and reduce product The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

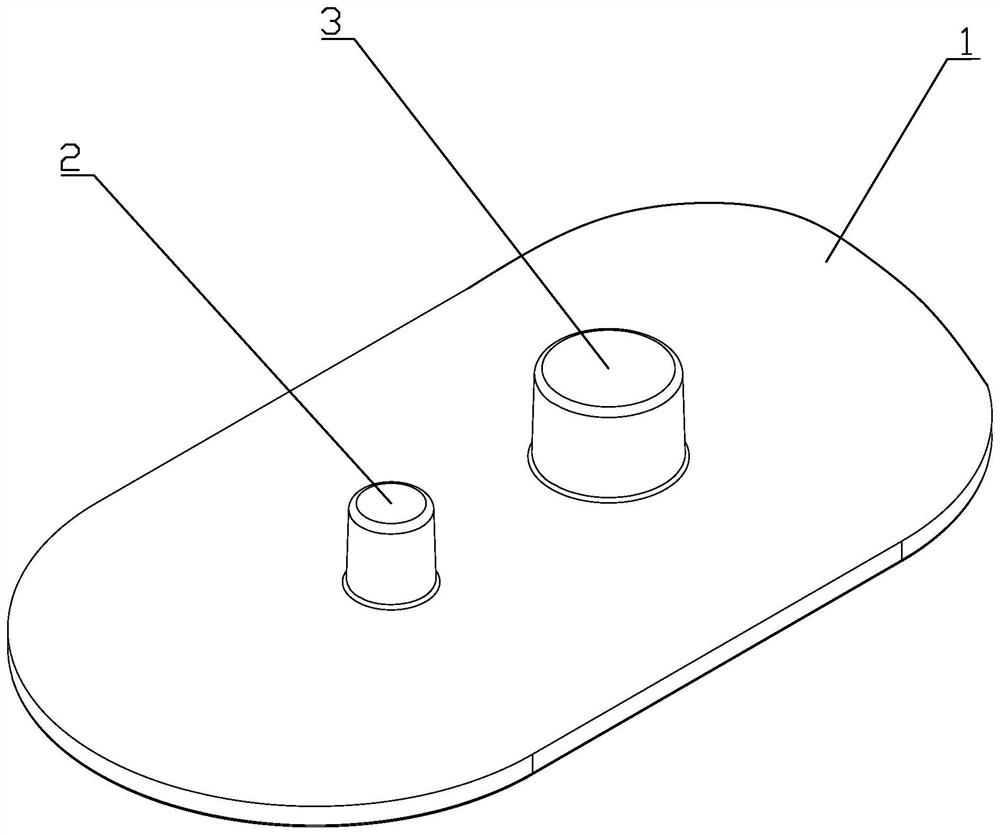

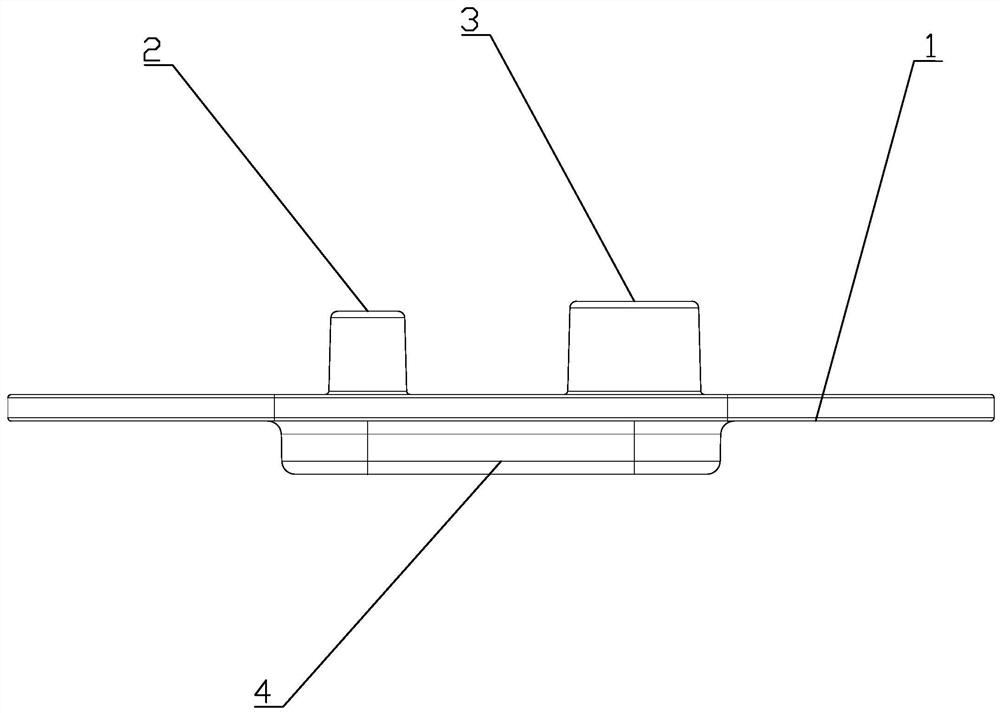

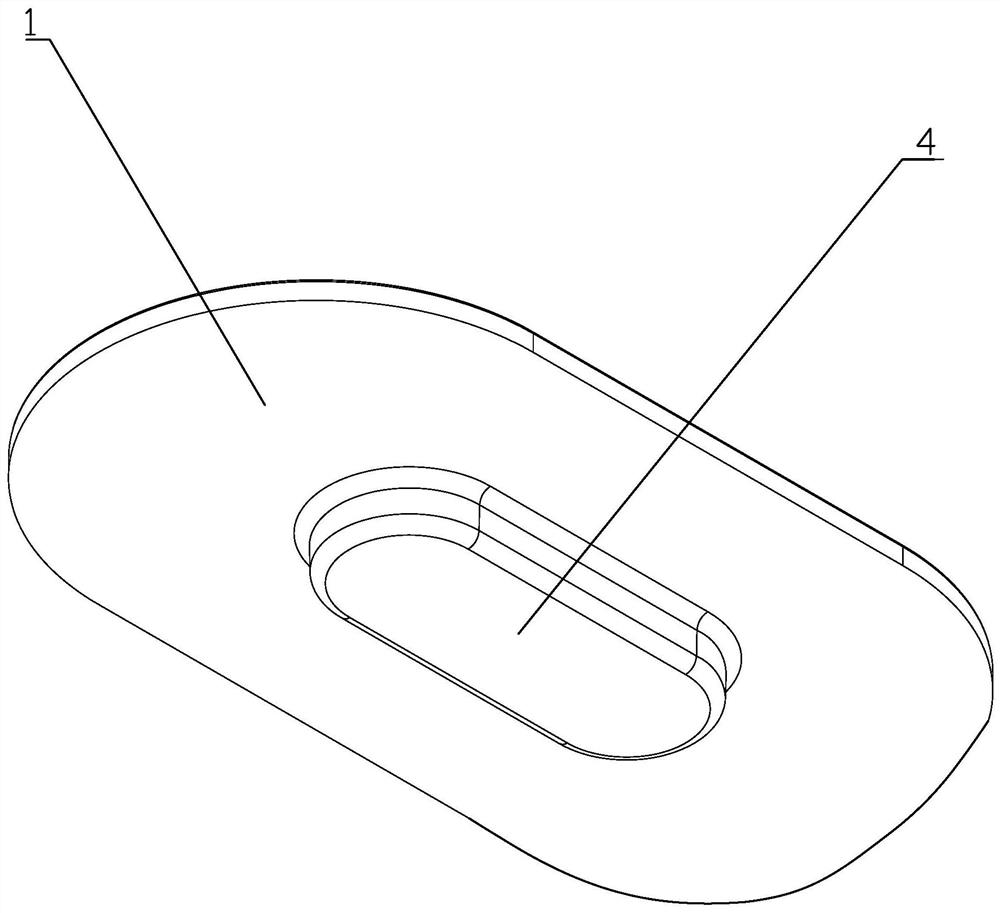

[0029] Such as Figure 1-3 As shown, a high-strength and light-weight automobile air-conditioning flange forging, the automobile air-conditioning flange forging includes a flange 1, the upper surface of the flange 1 is provided with a first column 2, a second column 3. Bosses 4 are provided on the lower surface; after the forgings of the present invention are prepared, they are used for finishing, specifically, the flanges 1 and the bosses 4 are installed along the axial direction of the first column 2 and the second column 3. Holes for mounting fixed connection joints. The flange 1 is used to fix and lock the sealing ring to prevent air leakage. The axes of the first column 2 and the second column 3 pass through the boss 4 . The diameter of the first column 2 is smaller than that of the second column 3 . The width of the boss 4 is greater than the diameter of the second column 3 , and the length is greater than the sum of the diameter of the first column 2 , the diameter o...

Embodiment 2

[0033] Structural part is with embodiment one. In order to effectively improve the strength of the forged piece while ensuring the forging performance, this embodiment uses the following alloy as the raw material, in terms of mass percentage: 1.3% silicon Si, 0.4% iron Fe, 0.2% copper Cu, and 0.5% manganese Mn %, Magnesium Mg 0.6%, Chromium Cr 0.20%, Zinc Zn 0.20%, Titanium Ti 0.05%, Holmium Ho 0.003%, Aluminum AL balance; Specifically prepare the automobile air-conditioning flange forgings according to the following procedures: using a fully automatic round Saw cutting, forging with a 400-ton forging press, edge trimming with an open tilting press, and shot blasting with a crawler-type shot blasting machine.

[0034] The performance testing data of the final forging are as follows: tensile strength σbMPa≥205; yield strength σ0.2MPa≥110; elongation δ10% ≥14.

Embodiment 3

[0036] Structural part is with embodiment one. In order to effectively improve the strength of the forged piece while ensuring the forging performance, this embodiment uses the following alloy as the raw material, in terms of mass percentage: 1.0% silicon Si, 0.4% iron Fe, 0.2% copper Cu, and 0.5% manganese Mn %, Magnesium Mg 0.6%, Chromium Cr 0.20%, Zinc Zn 0.20%, Titanium Ti 0.05%, Holmium Ho 0.003%, Aluminum AL balance; Specifically prepare the automobile air-conditioning flange forgings according to the following procedures: using a fully automatic round Saw cutting, forging with a 400-ton forging press, edge trimming with an open tilting press, and shot blasting with a crawler-type shot blasting machine.

[0037] The performance testing data of the final forging are as follows: tensile strength σbMPa≥209; yield strength σ0.2MPa≥115; elongation δ10% ≥14.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com