Method for removing soluble silicon dioxide in scheelite beneficiation wastewater

A mineral processing wastewater and silica technology, applied in mining wastewater treatment, chemical instruments and methods, multi-stage water treatment, etc., can solve problems such as high content of soluble silica, removal of soluble silica, impact of wastewater reuse, etc. , to achieve the effect of saving mineral processing cost, solving refractory treatment, and high wastewater reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 :( laboratory simulation and mineral processing water samples back experimentally)

[0029] The method of removing waste mineral scheelite a soluble silica of the present invention, comprising the steps of:

[0030] (1) analog formulated water sample containing soluble silica is sodium silicate, wherein the soluble SiO 2 Concentration controlled at about 400mg / L;

[0031] (2) The amount of lime per cubic wastewater in an amount of 500g, lime is added to the water samples the analog stirred 3min, 30min to obtain a first supernatant after settling;

[0032] (3) addition of 200g / m to the first supernatant 3 Calcium chloride, 2min after stirring the pH adjusted to 12 by adding sodium hydroxide, stirring for 2min settling 30min, to obtain a second supernatant;

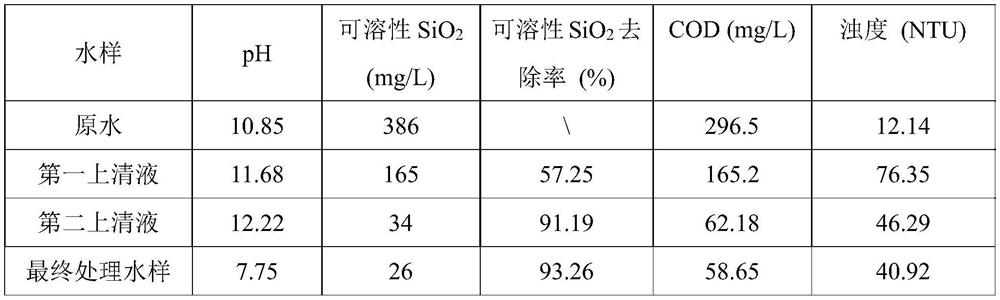

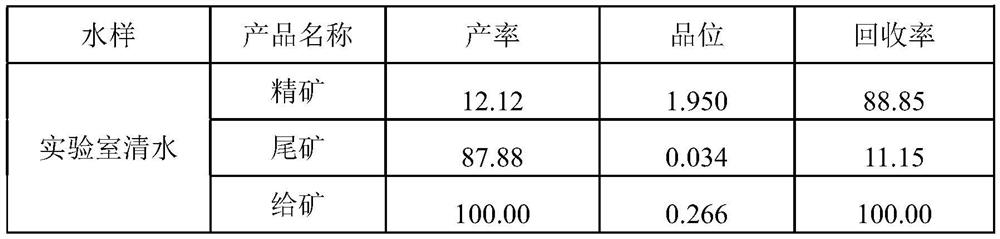

[0033] (4) H 2 SO 4 The second supernatant was adjusted to a neutral pH to give the final treated water sample, a detection result of the water quality of the various stages shown in Table 1; and finally th...

Embodiment 2

[0039] Example 2 (Xintianling dressing wastewater treatment and reuse Tungsten test) Embodiment:

[0040] Scheelite removing one inventive dressing wastewater in the process (Xintianling tungsten ore beneficiation waste water) soluble silica, comprising the steps of:

[0041] (1) in accordance with an amount of lime per cubic meter of waste water in an amount of lime added to 600g of tungsten ore dressing wastewater stirred 5min, 40min to obtain a first supernatant after settling;

[0042] (2) was added 200g / m to the first supernatant 3 Calcium chloride, and the pH adjusted to about 12, a white precipitate was stirred 2min, sedimentation 30min, to obtain a second supernatant;

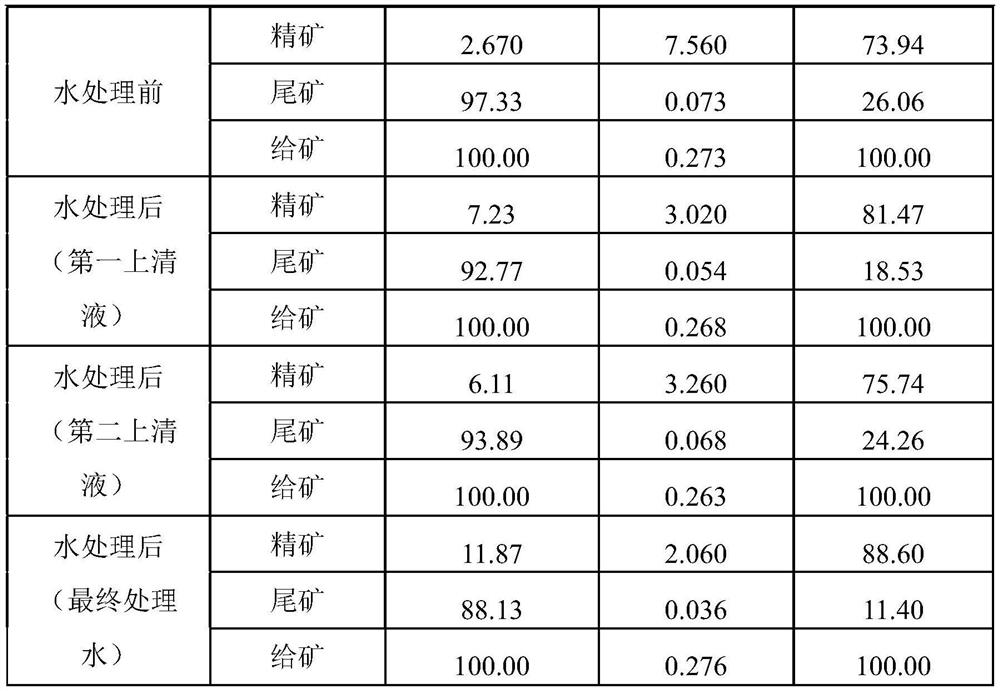

[0043] (3) H 2 SO 4 The second supernatant was adjusted to neutral pH, to obtain water samples (each stage of the processing and beneficiation waste water analysis As shown in Table 3) after the treatment process; various stages of processing of the last water samples scheelite flotation open validation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com