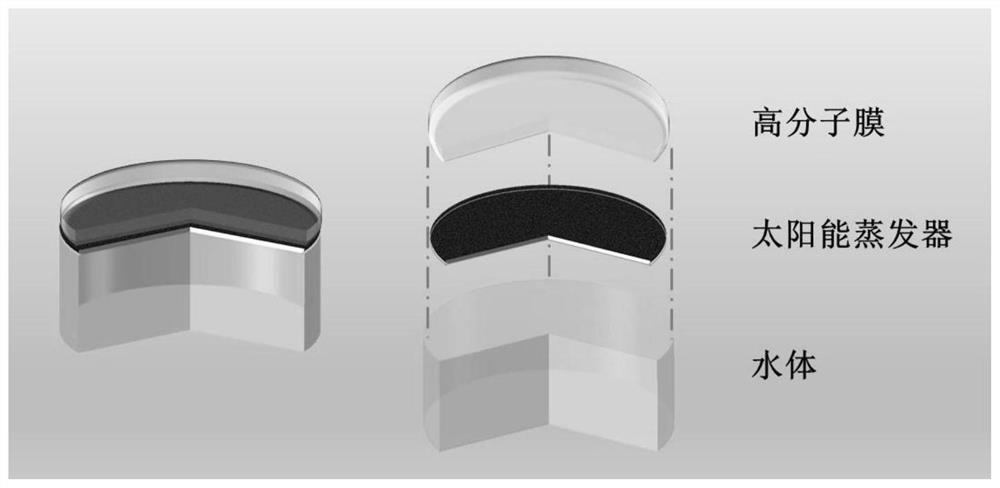

Polymer membrane with hierarchical porous structure and preparation method and application thereof

A polymer membrane, pore structure technology, applied in chemical instruments and methods, general water supply conservation, water/sludge/sewage treatment, etc., can solve the problems of heat loss, energy loss, aggravated heat conduction and heat radiation loss, etc. Low cost, stable product shape and structure, and high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

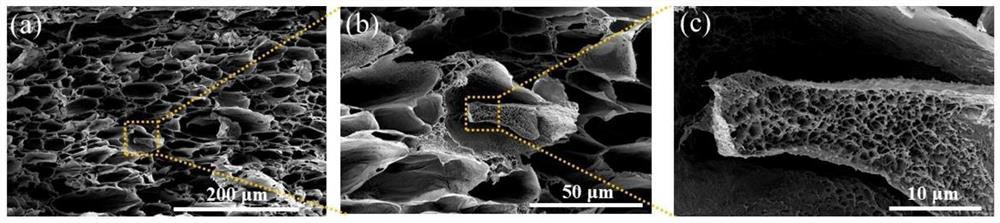

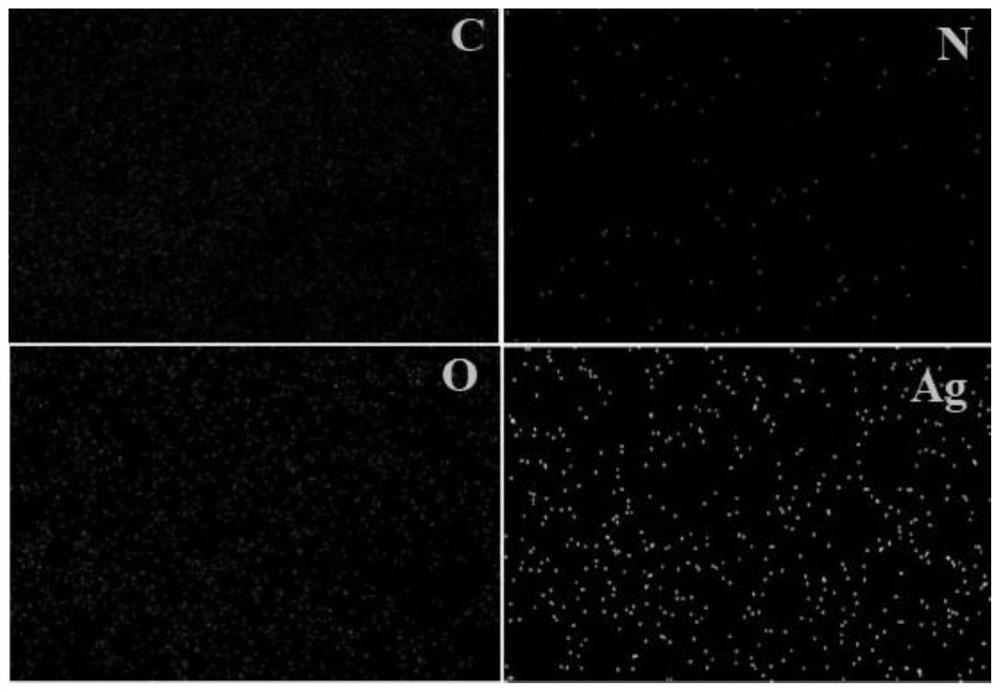

[0037] A kind of polyvinyl alcohol hydrogel film of hierarchical porous structure, its preparation is carried out according to the following steps:

[0038] Get 4g of polyvinyl alcohol powder and 1g of polyethylene glycol and add it to a mixed solution of 50ml of deionized water and glycerol (the mass ratio of water and glycerol in the mixed solution is 1:1), and then place React at 98°C for 1 hour; add 5 mg of silver nitrate crystals into an aqueous solution and add to the above solution, place at 70°C for 12 hours; then pour the solution into a mold to form a film and place it at -20°C for gelation Treatment; the products after gelation were respectively placed in sodium tetraborate solution, ethanol solution, and aqueous solution for cross-linking and selective etching, and finally obtained a polyvinyl alcohol hydrogel film (sample 1), which showed micron and nanometer Level of hierarchical porous structure. The average size of the prepared micropores is 25 μm, and the ave...

Embodiment 2

[0045] A kind of polyvinyl alcohol hydrogel film of hierarchical porous structure, its preparation is carried out according to the following steps:

[0046] Take 4g of polyvinyl alcohol powder and 1g of polyethylene oxide and add it to a mixed solution of 50ml of deionized water and glycerol, the mass ratio of the mixed solution is 1:1; place it at 98°C for 1 hour; put 1mg of Silver nitrate crystals were prepared as an aqueous solution and added to the above solution, and placed at 70°C for 12 hours of reaction; then the solution was poured into a mold to form a film and placed at -20°C for gelation treatment; the gelled products were successively Place in sodium tetraborate solution, ethanol solution, and aqueous solution for cross-linking, selective etching, and water absorption treatment, and finally obtain a polyvinyl alcohol hydrogel film (sample 2), which presents a micro- and nano-scale hierarchical porous structure. The average size of the prepared micropores is 5 μm, ...

Embodiment 3

[0049] A kind of polyvinyl alcohol hydrogel film of hierarchical porous structure, its preparation is carried out according to the following steps:

[0050] Take 4g of polyvinyl alcohol powder and 1g of polyethylene glycol and add it to a mixed solution of 50ml of deionized water and propylene glycol, the mass ratio of the mixed solution is 1:1, and place it at 98°C for 1 hour; add 1mg of nitric acid The silver crystals are prepared as an aqueous solution and added to the above solution, and placed at 70°C for 12 hours of reaction; then the solution is poured into a mold to form a film and placed at -20°C for gelation treatment; the gelled products are placed successively Cross-linking, selective etching, and water absorption were carried out in sodium tetraborate solution, ethanol solution, and aqueous solution, and finally a polyvinyl alcohol hydrogel film (sample 3) was obtained, which exhibited a hierarchical porous structure of micron and nanometer levels. The average siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com