Anticorrosive water-based acrylic polyurethane finish paint and preparation process thereof

An acrylic polyurethane and topcoat technology, which is applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of paint fading, incomplete painting of the painted surface, and large surface tension of paint emulsions, and achieve insulation External effects of increasing and decreasing liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An anti-corrosion type water-based acrylic polyurethane topcoat, comprising the following components by weight: 80 components of acrylic polyurethane resin, 3 components of toluene diisocyanate, 10 components of homoarginine, 2 components of methyl isobutyl ketone, 5 components Triethylamine, 10 components of leveling agent, 6 components of wetting agent, 5 components of film-forming auxiliary agent, 15 components of hydrophilic chain extender, 2 components of thickener, 0.5 component of organometallic catalyst, 30 Component dyeing pigment and 80 components of deionized water, wherein the film-forming auxiliary agent is propylene glycol butyl ether and propylene glycol methyl ether acetate mixed in a ratio of 1:1, and the wetting agent is ethanol, propylene glycol, dimethyl sulfoxide It is prepared by mixing with polyethylene glycol in a ratio of 4:2:1:2.

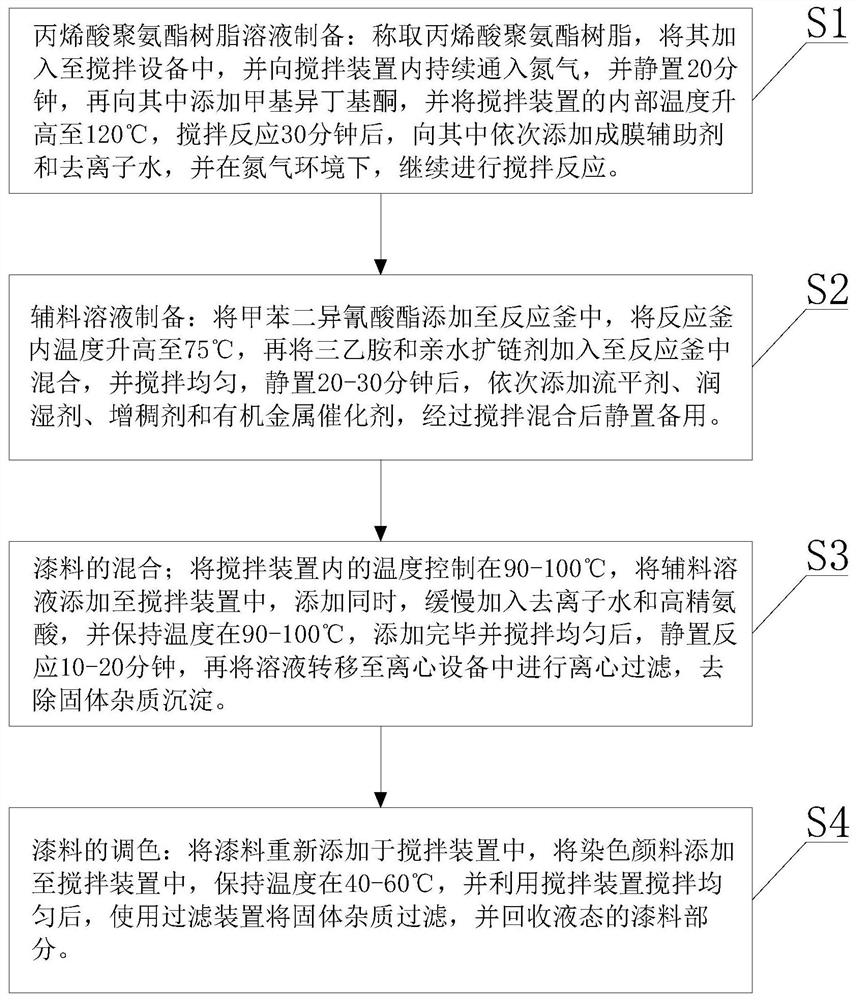

[0025] see figure 1 , in order to better demonstrate the preparation process of anti-corrosion water-based acryli...

Embodiment 2

[0031] An anti-corrosion type waterborne acrylic polyurethane topcoat, comprising the following components by weight: 80 components of acrylic polyurethane resin, 4 components of toluene diisocyanate, 15 components of homoarginine, 2 components of methyl isobutyl ketone, 5 components Triethylamine, 10 components of leveling agent, 6 components of wetting agent, 5 components of film-forming auxiliary agent, 15 components of hydrophilic chain extender, 2 components of thickener, 0.5 component of organometallic catalyst, 30 Component dyeing pigment and 80 components of deionized water, wherein the film-forming auxiliary agent is propylene glycol butyl ether and propylene glycol methyl ether acetate mixed in a ratio of 1:1, and the wetting agent is ethanol, propylene glycol, dimethyl sulfoxide It is prepared by mixing with polyethylene glycol in a ratio of 4:2:1:2.

[0032] see figure 1 , in order to better demonstrate the preparation process of anti-corrosion water-based acrylic p...

Embodiment 3

[0038] An anti-corrosion type waterborne acrylic polyurethane topcoat, comprising the following components by weight: 80 components of acrylic polyurethane resin, 5 components of toluene diisocyanate, 20 components of homoarginine, 2 components of methyl isobutyl ketone, 5 components Triethylamine, 10 components of leveling agent, 6 components of wetting agent, 5 components of film-forming auxiliary agent, 15 components of hydrophilic chain extender, 2 components of thickener, 0.5 component of organometallic catalyst, 30 Component dyeing pigment and 80 components of deionized water, wherein the film-forming auxiliary agent is propylene glycol butyl ether and propylene glycol methyl ether acetate mixed in a ratio of 1:1, and the wetting agent is ethanol, propylene glycol, dimethyl sulfoxide It is prepared by mixing with polyethylene glycol in a ratio of 4:2:1:2.

[0039] see figure 1 , in order to better demonstrate the preparation process of anti-corrosion water-based acrylic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com