A kind of preparation method of hydrophilic corn insulating oil modified by nano-magnesium oxide

A technology of nano-magnesium oxide and insulating oil, which is applied in the fields of magnesium oxide, petroleum industry, dyed organic silicon compound treatment, etc., can solve the problems of damage to insulating paper, irreversible decline in mechanical properties and insulation performance of insulating paper, and reduce agglomeration and reduce The effect of water diffusion to improve dispersibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

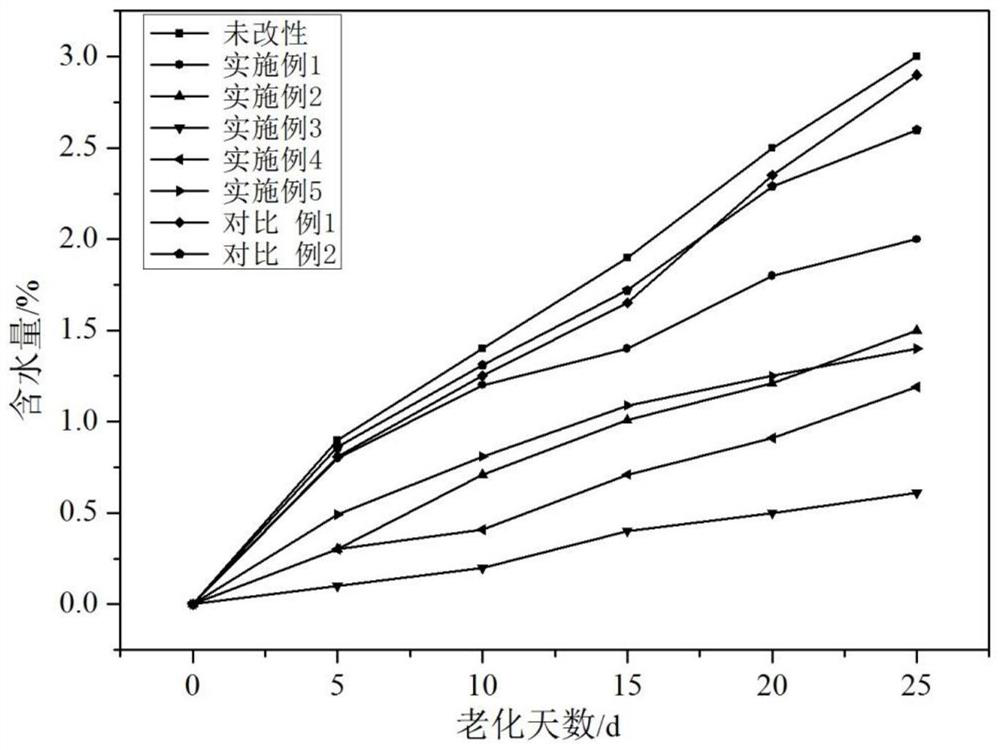

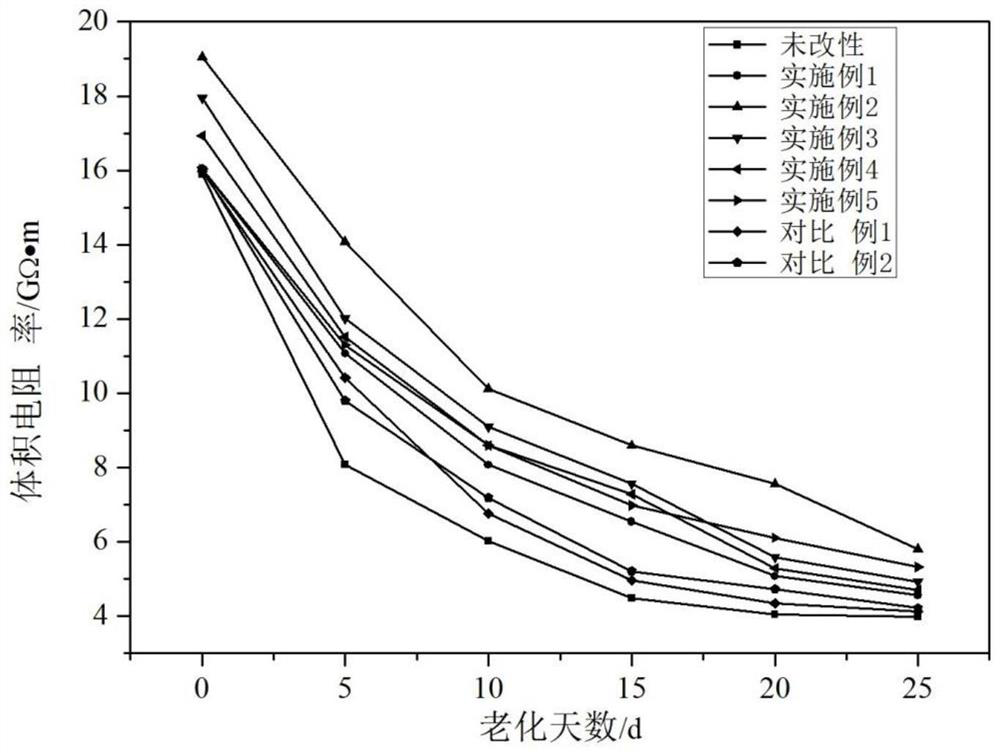

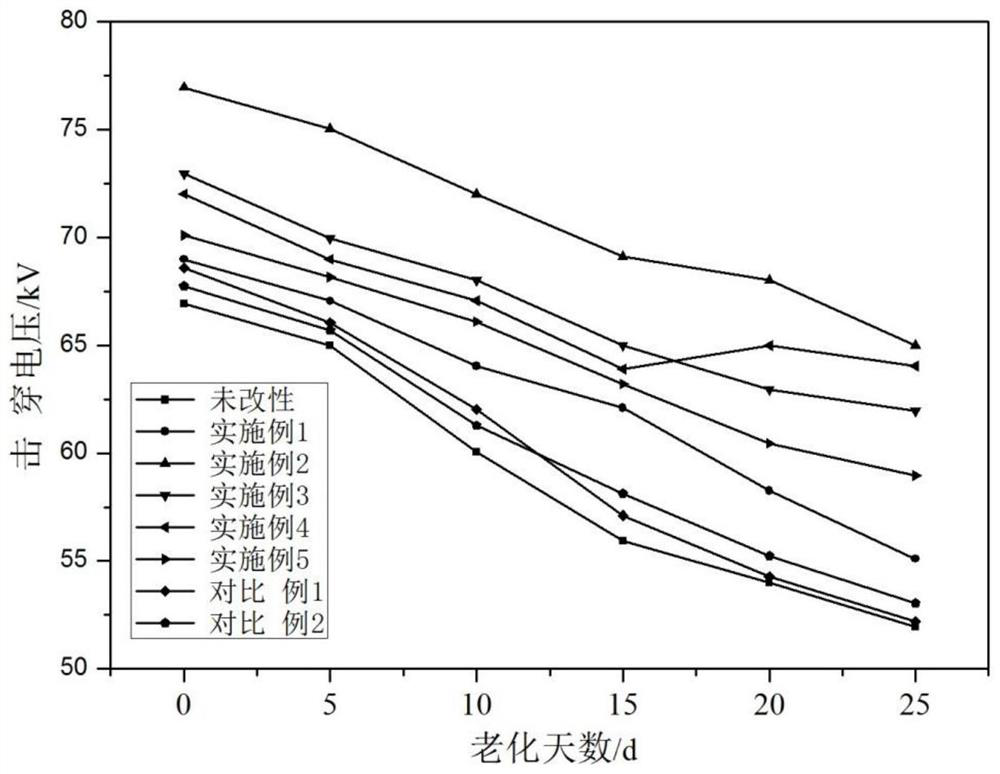

Examples

Embodiment 1

[0028] A preparation method of hydrophilic corn insulating oil modified by nano-magnesium oxide, comprising the following steps:

[0029] (1) drying the corn insulating oil in a vacuum at 100°C for 24 hours, then heating the corn insulating oil to 60°C, mechanically stirring, the stirring speed is 50r / min, and the stirring time is 30min to obtain the pretreated corn insulating oil;

[0030] (2) in the pretreated corn insulating oil obtained in step (1), add nano-magnesium oxide, and the addition of nano-magnesium is 1% of the weight of the pre-treated corn insulating oil, then carry out ultrasonic oscillation, ultrasonic oscillation power is 1000W, time For 30min, the hydrophilic corn insulating oil was obtained.

[0031] Wherein, the preparation method of nano-magnesium oxide comprises the following steps:

[0032] ① Add 1.5% of the weight of magnesium nitrate crystal control agent to the magnesium nitrate solution with a concentration of 0.2mol / L. The crystal control agent ...

Embodiment 2

[0036] The difference between this example and Example 1 is that the addition amount of nano-magnesium oxide in step (2) is 2% of the weight of the pretreated corn insulating oil, and other steps and process parameters are the same as those in Example 1.

Embodiment 3

[0038] The difference between this example and Example 1 is that the amount of nano-magnesium oxide added in step (2) is 3% of the weight of the pretreated corn insulating oil, and other steps and process parameters are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com