Hydrolat concentration method and device

An extraction method and extraction device technology, applied in the field of plant extraction, can solve the problems of high energy consumption, long use time, and high cost of rose water, and achieve the effects of shortening the production cycle, increasing the concentration of ingredients, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

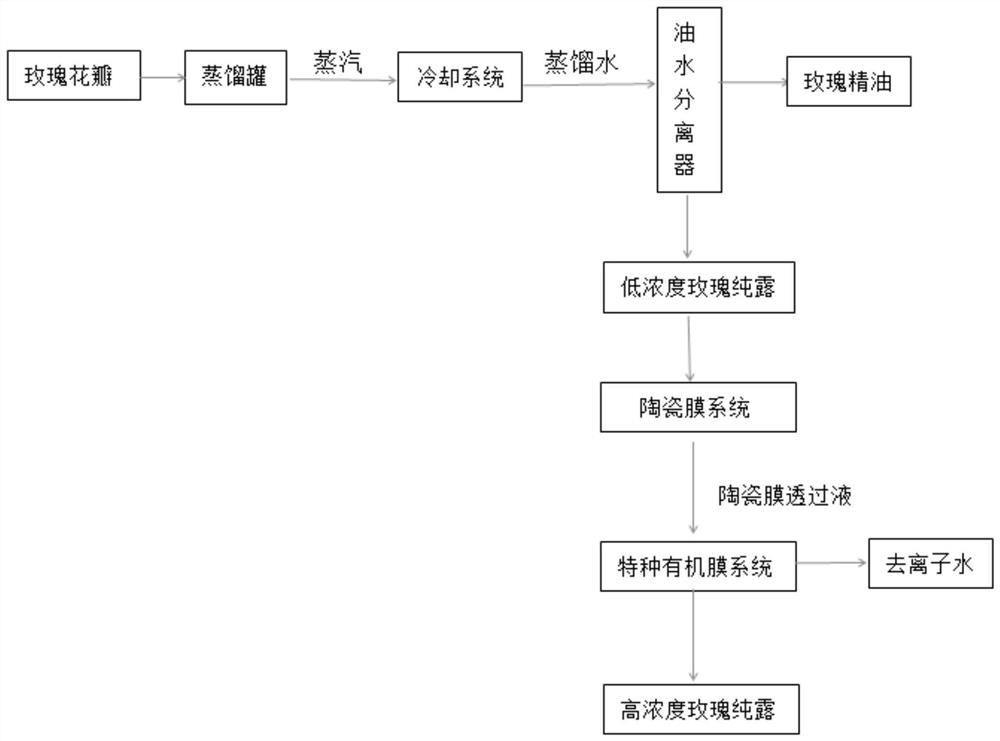

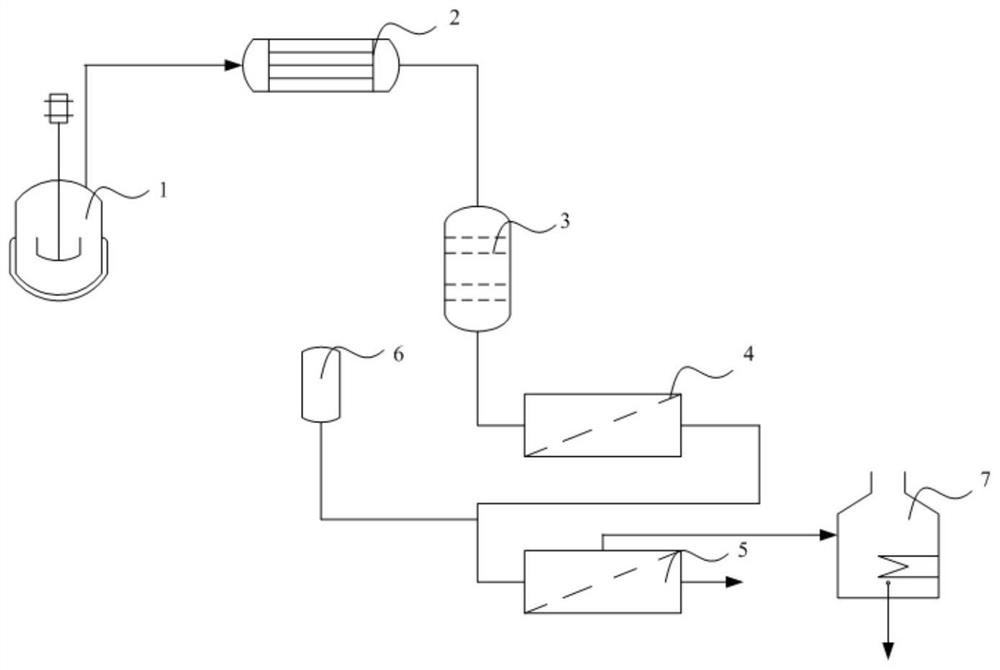

[0067] 1. Put the plucked rose petals into the retort, inject water vapor, the first distillation time is 5 hours, then stop the distillation and let it stand for 1 hour. The second pass into steam distillation, distillation time is 3h.

[0068] 2. Pass the distilled steam into the cooling system for condensation to obtain distilled water.

[0069] 3. Pass the distilled water into the oil-water separator. Under low temperature conditions, due to the difference in density, rose essential oil floats on the top and distilled water on the bottom. Rose essential oil is extracted into the essential oil storage container to obtain low concentration rose water.

[0070] 4. The low-concentration rose pure dew obtained above is clarified and decontaminated by a ceramic membrane system to remove suspended solids and insoluble impurities. The pore diameter of the ceramic membrane filter element is 50 nanometers, the channel diameter is 4 mm, and the membrane surface flow rate is 4m / s,...

Embodiment 2

[0073] 1. Put the plucked rose petals into the retort, inject water vapor, the first distillation time is 5 hours, then stop the distillation and let it stand for 1 hour. The second pass into steam distillation, distillation time is 3h.

[0074] 2. Pass the distilled steam into the cooling system for condensation to obtain distilled water.

[0075] 3. Pass the distilled water into the oil-water separator. Under low temperature conditions, due to the difference in density, rose essential oil floats on the top and distilled water on the bottom. Rose essential oil is extracted into the essential oil storage container to obtain low concentration rose water.

[0076] 4. The low-concentration rose pure dew obtained above is clarified and decontaminated by a ceramic membrane system to remove suspended solids and insoluble impurities. The pore diameter of the ceramic membrane filter element is 30 nanometers, the channel diameter is 4 mm, and the membrane surface flow rate is 4m / s,...

Embodiment 3

[0079] The difference from Example 2 is that the dialysis treatment is performed by adding pure water during the treatment process of the ceramic membrane system.

[0080] 1. Put the plucked rose petals into the retort, inject water vapor, the first distillation time is 5 hours, then stop the distillation and let it stand for 1 hour. The second pass into steam distillation, distillation time is 3h.

[0081] 2. Pass the distilled steam into the cooling system for condensation to obtain distilled water.

[0082] 3. Pass the distilled water into the oil-water separator. Under low temperature conditions, due to the difference in density, rose essential oil floats on the top and distilled water on the bottom. Rose essential oil is extracted into the essential oil storage container to obtain low concentration rose water.

[0083] 4. The low-concentration rose pure dew obtained above is clarified and decontaminated by a ceramic membrane system to remove suspended solids and insolu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com