Gas diffusion layer, preparation method and application thereof, and fuel cell

A gas diffusion layer and slurry technology, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as flooding failure, high cost, affecting fuel cell performance and service life, etc., and achieve the effect of improving peak power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

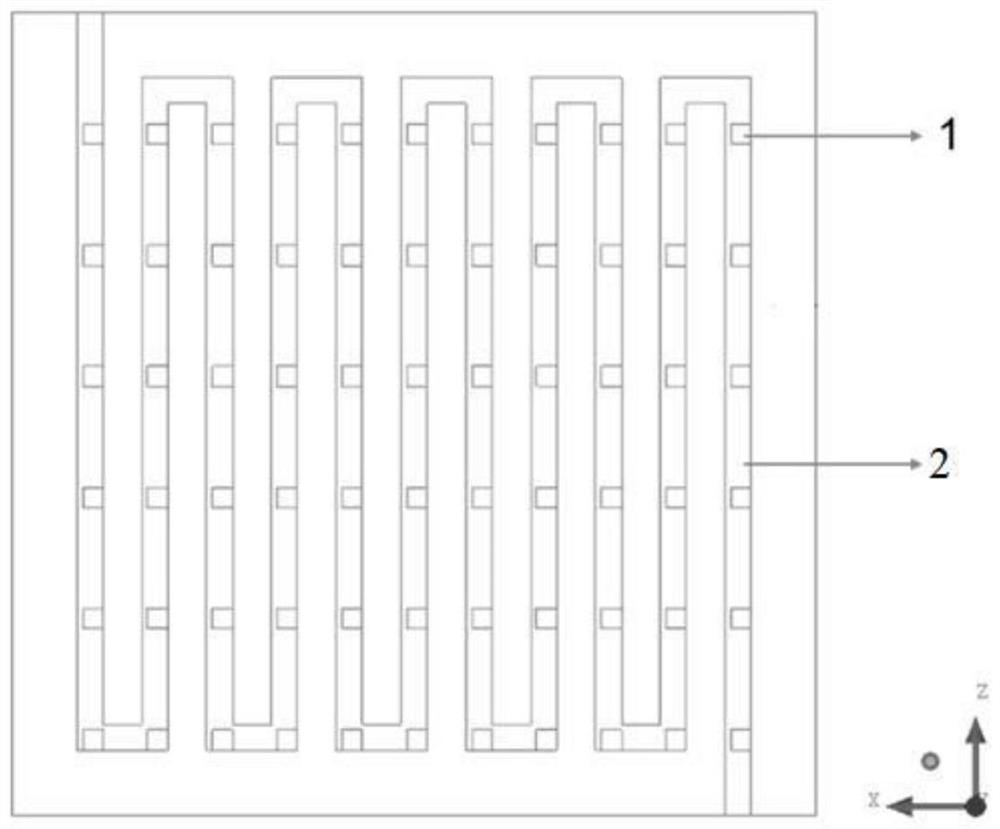

Image

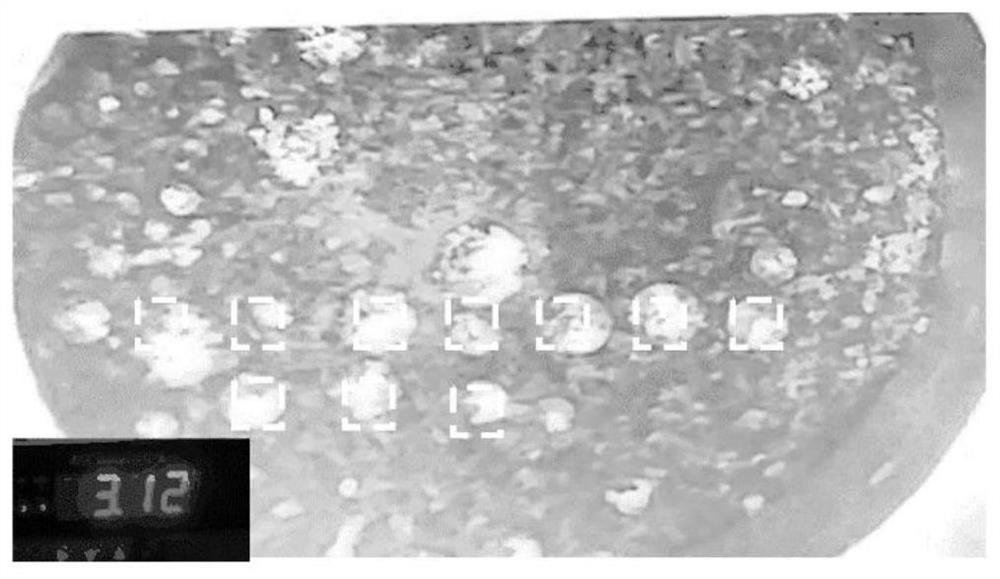

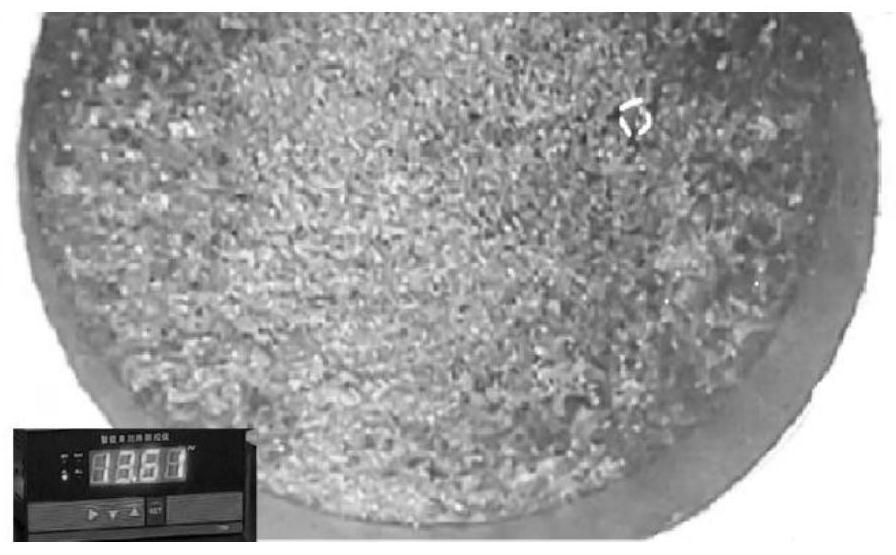

Examples

Embodiment 1

[0090] S1: Preparation of the base layer: place the carbon paper in an acetone solution for 30 minutes, take it out and put it in a 60°C oven for drying, soak it in a PTFE emulsion with a mass fraction of 10%, and then put it in the oven for drying, repeat several times times until the loading of PTFE on carbon paper reaches 30%.

[0091] Microporous layer preparation: Weigh 0.01g of ammonium chloride and add 0.02g of deionized water to form an ammonium chloride solution, take 0.03g each of SuperP, AB type carbon black and Vulcan XC-72, 8g of deionized water, 10g of isopropanol, Mix 0.6 g of 10% wt polytetrafluoroethylene emulsion, add the above ammonium chloride solution, and ultrasonically disperse for 3 hours to form a microporous layer slurry. The microporous layer slurry is sprayed onto the base layer by pressure spraying so that the loading of the conductive material is 2 mg / cm 2 , and then placed in a muffle furnace for sintering at 360°C for 1h.

[0092]S2: Wetting s...

Embodiment 2

[0094] In S1, the mass of the conductive material Super P, AB carbon black, and Vulcan XC-72 is changed to 0.035g; in S2, the size of the wettability module is changed to 0.4mm*0.4mm, and the center distance is changed to 2mm. The area ratio of the flow channel is 11%, and other operations and conditions are the same as in Example 1.

Embodiment 3

[0096] In S2, the wettability reagent was changed to sodium dodecylalanine, the film-forming agent was changed to polyvinyl alcohol, the size of the wettability module was changed to 0.3mm*0.3mm, the distance between centers was changed to 3mm, and the wettability part The area ratio of the flow channel is 6%, and other operations and conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com