Preparation method of silicon nanospheres

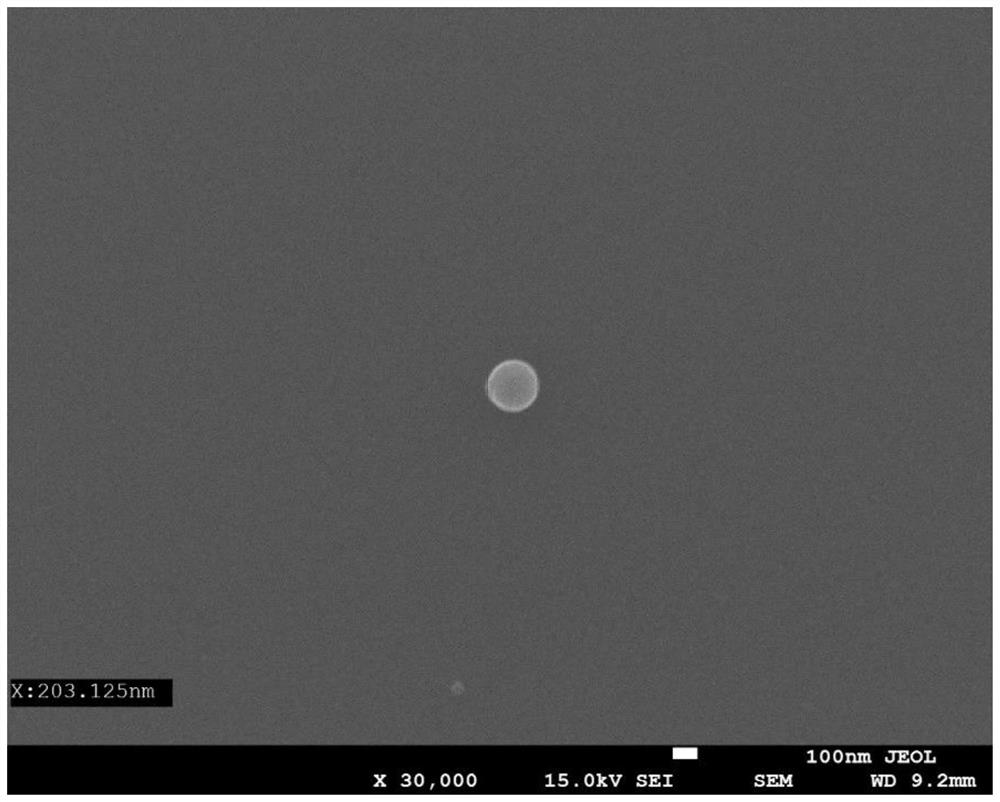

A silicon nanometer and silicon wafer technology is applied in the field of preparation of silicon nanospheres, which can solve the problems of complex production process, small average particle size of silicon nanoparticle, fixed reaction area, etc., and achieves green environmental protection, large diameter, and easy operation in the preparation process. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing silicon nanospheres, comprising the following steps:

[0037] Step 1: Ultrasonic cleaning of silicon wafers;

[0038] Step 2: Fix the cleaned silicon wafer in a quartz petri dish filled with deionized water, and fix the quartz sample cell above the three-dimensional electric translation stage of the femtosecond laser micro-nano processing system;

[0039] Step 3: Focus the femtosecond pulsed laser on the surface of the silicon wafer;

[0040] Step 4: Use the motion control software to set the movement parameters of the three-dimensional electric translation platform;

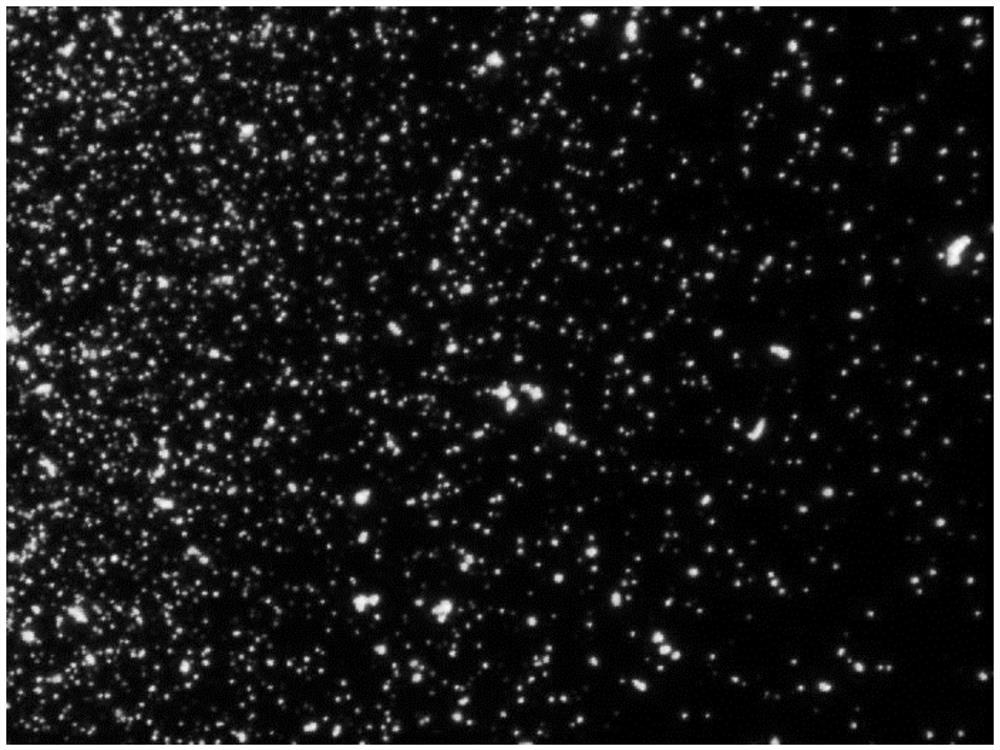

[0041] Step 5: The silicon wafer is moved by program control, and the femtosecond pulse laser ablates the surface of the silicon wafer to obtain a pale yellow colloidal silicon nano-water solution.

Embodiment 1

[0043] 1. The silicon wafer (10mm×12mm) and a quartz Petri dish were ultrasonically cleaned in deionized water for 20 minutes, and then dried.

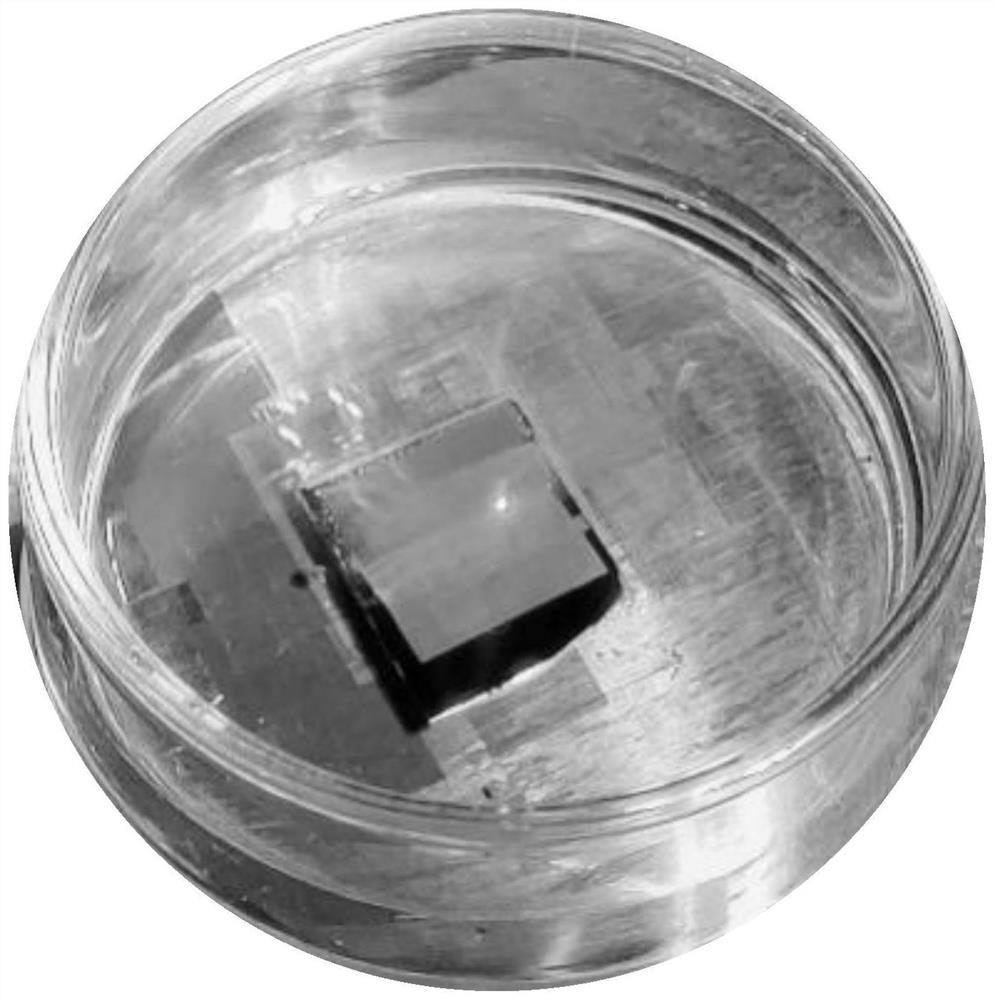

[0044] 2. Fix the cleaned silicon wafer in a quartz petri dish filled with 3ml deionized water, and fix the quartz sample cell on the femtosecond laser micro-nano processing system.

[0045] 3. Lead the laser to the top of the three-dimensional electric translation platform of the femtosecond laser micro-nano processing system. The output center wavelength of the laser amplification stage used is 800nm, the pulse width is 100fs, and the repetition frequency is 1kHz. The laser power can be continuously adjusted to 4mW by combining a half-wave plate and a Glan prism. The laser is focused by a lens with a focal length of 15cm and irradiates the silicon wafer. On the surface, the diameter of the focused spot is about 40 μm.

[0046] 4. Use the motion control software to set the moving parameters of the three-dimensional electric translat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com