A kind of ag loaded with platinum and silver nanoparticles 0.333 v 2 o 5 Nanorod composites and their preparation and application

A technology of silver nanoparticles and nanorods, which is applied to the composite material of photoelectric catalytic oxidation reaction. The preparation field of the above composite material can solve the problem of low utilization rate of visible light by semiconductors, and achieve suitable for mass production, uniform distribution, photoelectric Effect of Catalytic Oxidation Performance Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

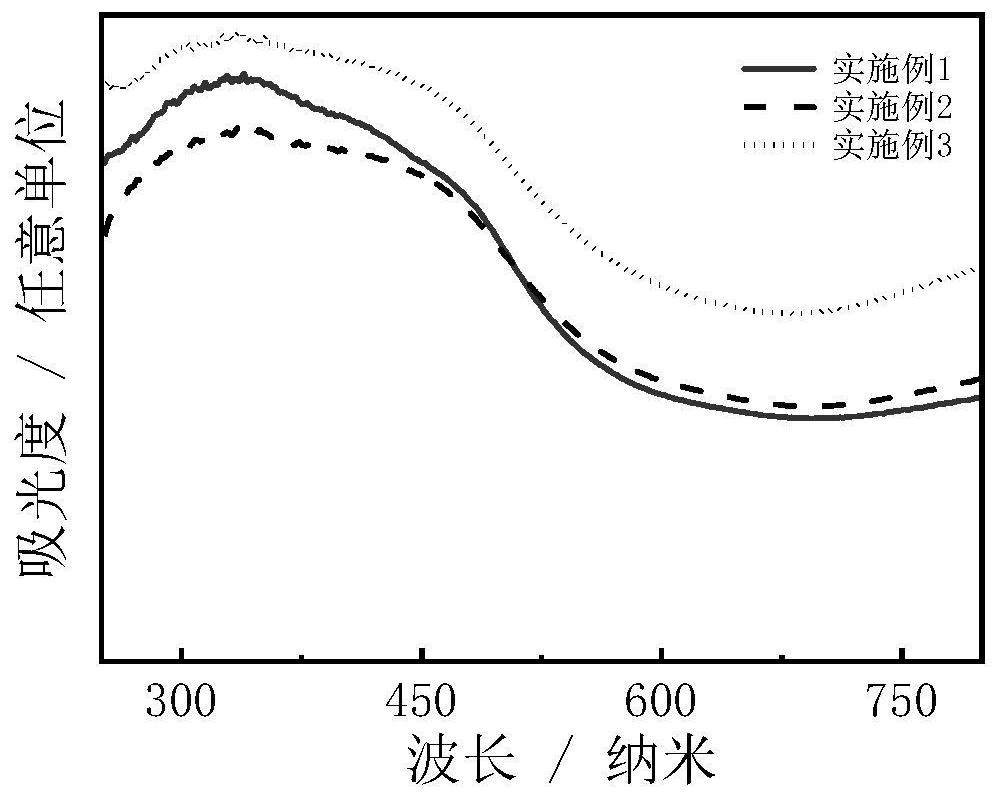

Embodiment 1

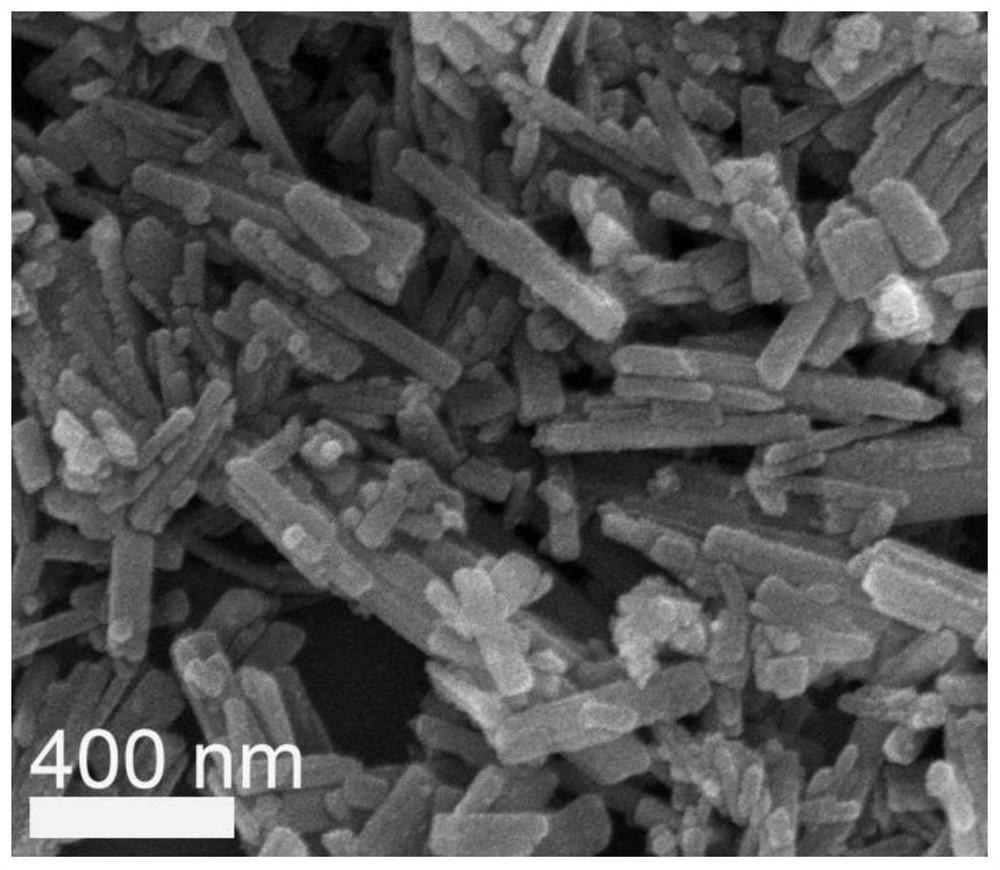

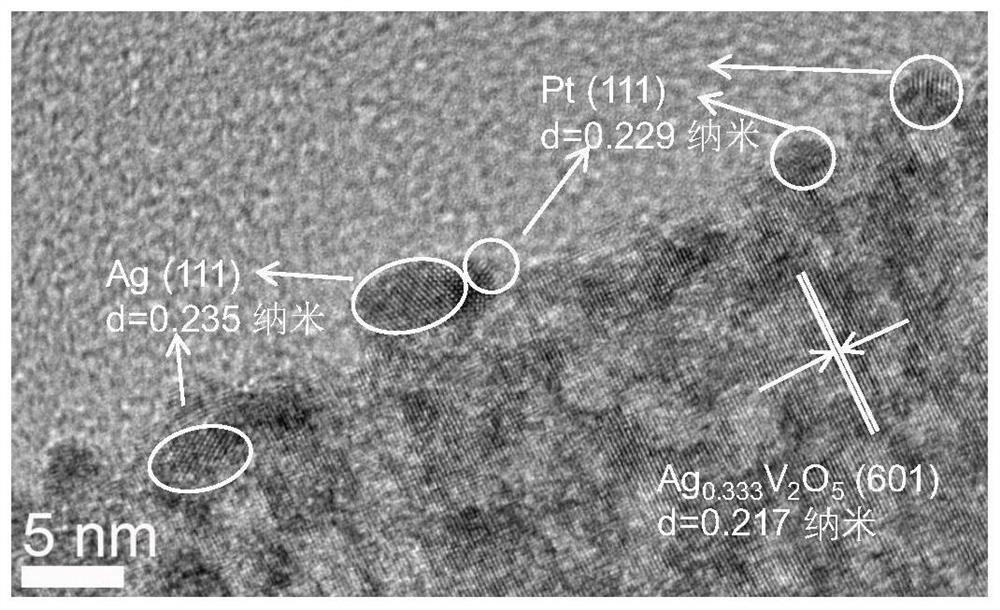

[0028] Step 1: Weigh 0.18 g of vanadium pentoxide powder, add 5 ml of hydrogen peroxide (30 wt %), and react vigorously for a few minutes to form a dark red solution. Pipette 50 ml of deionized water into the above solution to form a reddish-brown transparent solution. Under the condition of magnetic stirring, 10 ml of silver nitrate solution (5 mmol / L) was slowly poured into the above solution. After stirring evenly, the mixed solution was transferred to a 100 ml polytetrafluoroethylene-lined reaction kettle, and the reaction kettle was placed in an oven at 180 degrees Celsius for 24 hours. After naturally cooling to room temperature, the precipitate was centrifuged, washed with deionized water and ethanol, and the obtained samples were dried in a blast drying oven for 24 hours to obtain sample Ag x V 2 O 5 .

[0029] Step 2: Put 95 mg Ag x V 2 O 5 Add 30 ml of deionized water and sonicate for 10 minutes. Add 1.330 mL of chloroplatinic acid aqueous solution with a con...

Embodiment 2

[0031] Step 1: Weigh 0.18 g of vanadium pentoxide powder, add 5 ml of hydrogen peroxide (30 wt%), and react vigorously for a few minutes to form a dark red solution. Pipette 35 ml of deionized water into the above solution to form a reddish-brown transparent solution. Under the condition of magnetic stirring, 25 ml of silver nitrate solution (5 mmol / L) was slowly poured into the above solution. After stirring evenly, the mixed solution was transferred to a 100 ml polytetrafluoroethylene-lined reaction kettle, and the reaction kettle was placed in an oven at 180 degrees Celsius for 24 hours. After cooling to room temperature naturally, the precipitate was centrifuged and used for Ionized water and ethanol were centrifuged and washed, and the obtained sample was dried in a blast drying oven for 24 hours to obtain sample Ag x V 2 O 5 .

[0032] Step 2 is the same as in Example 1.

Embodiment 3

[0034] Step 1: Weigh 0.18 g of vanadium pentoxide powder, add 5 ml of hydrogen peroxide (30 wt %), and react vigorously for a few minutes to form a dark red solution. Pipette 20 ml of deionized water into the above solution to form a reddish-brown transparent solution. Under magnetic stirring, 40 ml of silver nitrate solution (5 mmol / L) was slowly poured into the above solution. After stirring evenly, the mixed solution was transferred to a 100-ml polytetrafluoroethylene-lined reaction kettle, and the reaction kettle was placed in an oven at 180 degrees Celsius for 24 hours. After cooling to room temperature naturally, the precipitate was centrifuged and used for Ionized water and ethanol were centrifuged and washed, and the obtained sample was dried in a blast drying oven for 24 hours to obtain sample Ag x V 2 O 5 .

[0035] Step 2 is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com