Nitrogen-phosphorus co-doped porous carbon material and preparation and application methods thereof

A porous carbon material and co-doping technology, applied in the field of water treatment, can solve the problem of low chloride ion electro-adsorption performance, and achieve the effects of controllable preparation method, improved removal efficiency, and improved electro-adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

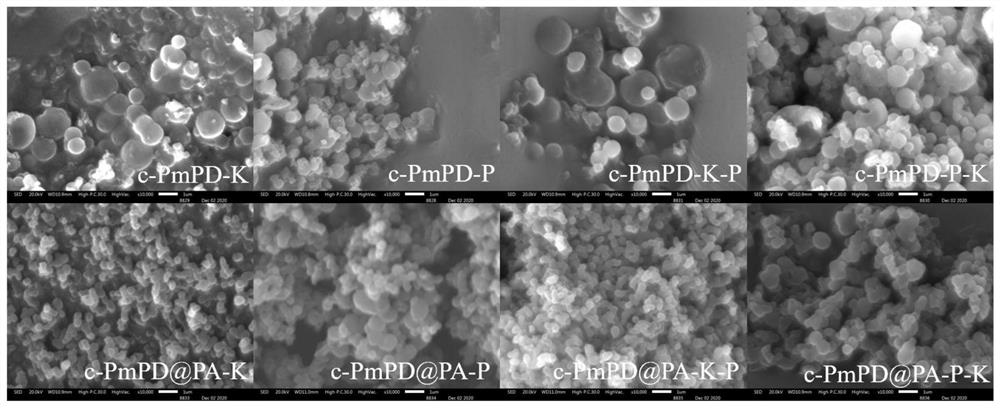

[0039]In order to obtain a nitrogen-phosphorus co-doped porous carbon material with high adsorption efficiency for chloride ions, the invention provides a method for preparing a nitrogen-phosphorus co-doped porous carbon material for electroadsorption of chloride ions, comprising steps:

[0040] S1, add the aqueous solution of persulfate and phytic acid solution to the aqueous solution of m-phenylenediamine to carry out polymerization reaction, and then sequentially separate, wash and dry the products obtained in the polymerization reaction to obtain poly-m-phenylenediamine@phytic acid particles.

[0041] Wherein, the step of adding the aqueous solution of persulfate and the phytic acid solution into the aqueous solution of m-phenylenediamine to carry out the polymerization reaction may include: adding the aqueous solution of persulfate and the phytic acid solution into the m-phenylenediamine Aqueous solution of amine, and carry out standing reaction at a temperature of 0-40°C...

Embodiment 1

[0106] A kind of material and preparation method thereof for electroadsorbing chloride ions

[0107] 1. Weigh 1g of m-phenylenediamine monomer and place it in a petri dish, add 10mL of deionized water, and magnetically stir to completely dissolve m-phenylenediamine to obtain an aqueous solution of m-phenylenediamine; weigh 2.6191g of sodium persulfate and set In a beaker, add 10mL of deionized water to dissolve it to obtain an aqueous solution of sodium persulfate.

[0108] 2. Add the aqueous solution of sodium persulfate dropwise into the petri dish containing the aqueous solution of m-phenylenediamine, then add 1.68mL 50% phytic acid solution, and let it stand for 24 hours to make the polymerization reaction complete; after the polymerization reaction ends, The product obtained by the polymerization reaction is separated by suction filtration, and then washed with 25-28% ammonia water and deionized water to remove impurities, and dried after washing, and the obtained black p...

Embodiment 2

[0113] A kind of material and preparation method thereof for electroadsorbing chloride ions

[0114] 1. Weigh 1g of m-phenylenediamine monomer and place it in a petri dish, add 10mL of deionized water, and magnetically stir to completely dissolve m-phenylenediamine to obtain an aqueous solution of m-phenylenediamine; weigh 2.6191g of sodium persulfate and set In a beaker, add 10mL of deionized water to dissolve it to obtain an aqueous solution of sodium persulfate.

[0115] 2. Add the aqueous solution of sodium persulfate dropwise into the petri dish containing the aqueous solution of m-phenylenediamine, then add 1.68mL 50% phytic acid solution, and let it stand for 24 hours to make the polymerization reaction complete; after the polymerization reaction ends, The product obtained by the polymerization reaction is separated by suction filtration, and then washed with 25-28% ammonia water and deionized water to remove impurities, and dried after washing, and the obtained black p...

PUM

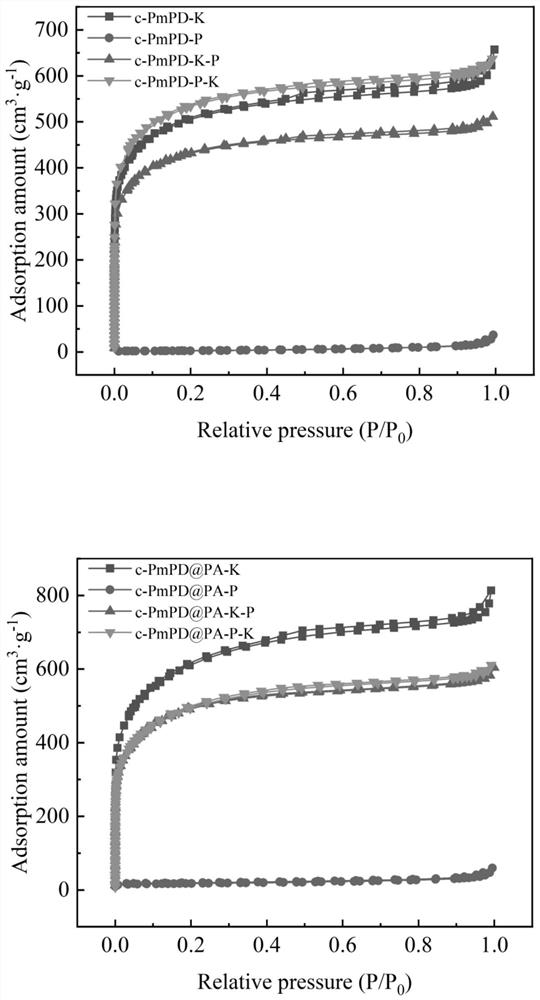

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com