Method and device for preparing sodium vanadate by taking vanadium fine slag as raw material

A technology of sodium vanadate and raw materials, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve the problems of low vanadium conversion rate, increased energy consumption, and low vanadium extraction efficiency, so as to improve vanadium conversion rate and improve The effect of contact area and avoiding material agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

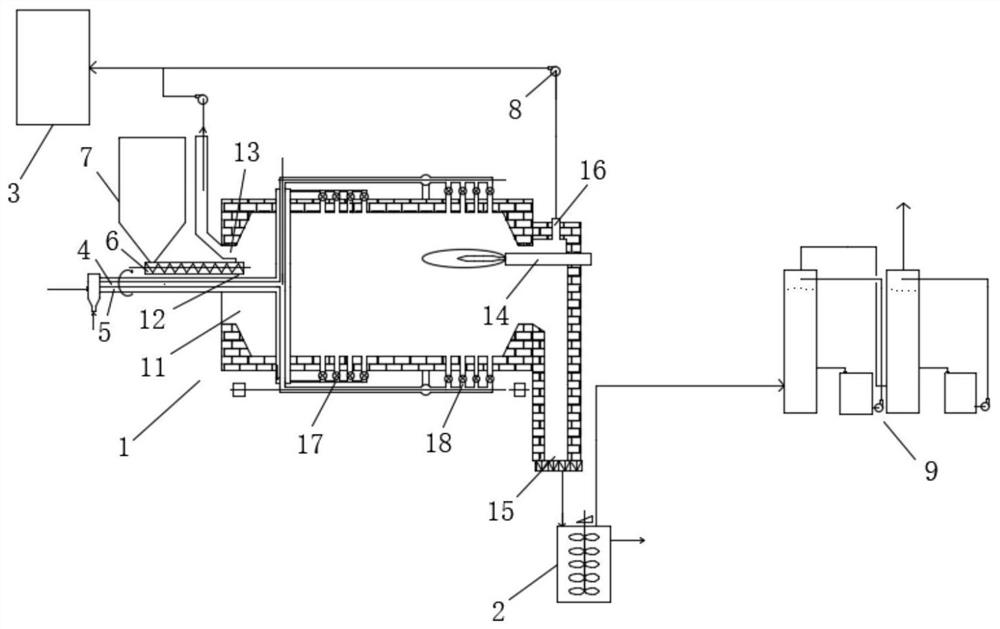

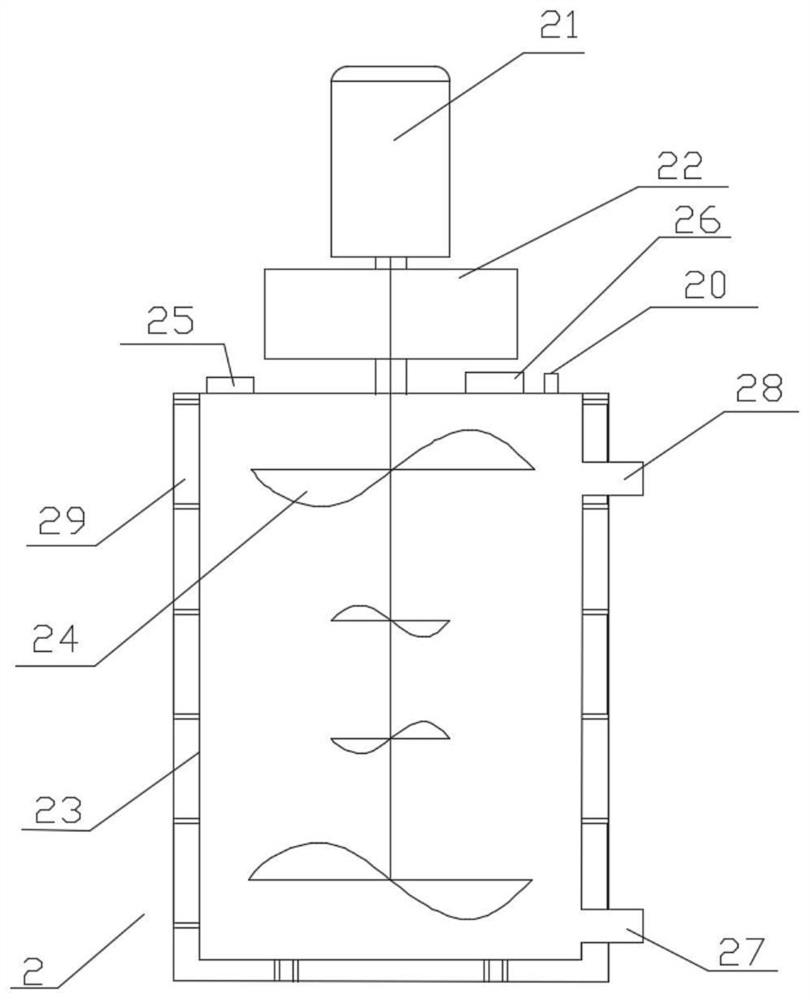

[0062] Present embodiment is a kind of method that takes vanadium concentrate slag as raw material to prepare sodium vanadate, and this method comprises the steps:

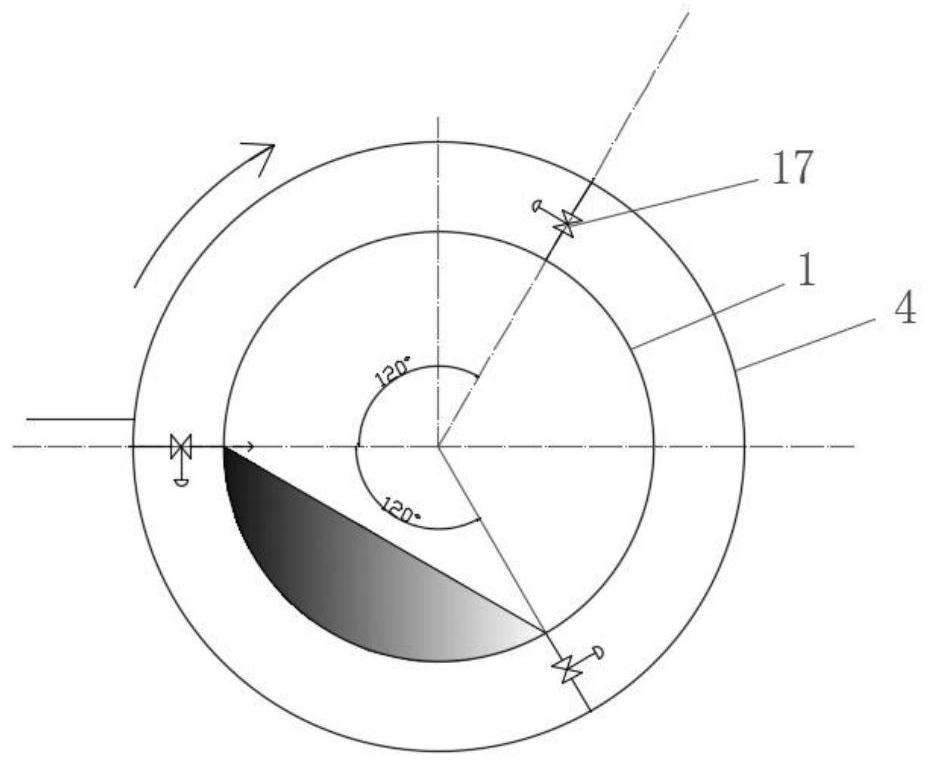

[0063] (a) Dry and grind the vanadium slag until the particle size is not less than 120 mesh, and remove the metallic iron through the automatic continuous dry electromagnetic iron remover to obtain the vanadium slag material, and then mix the vanadium slag material with the sodium salt additive , obtain mixed material, wherein, the content of MFe is 2.43% in the vanadium fine slag material, and the mass ratio of vanadium fine slag material and sodium salt additive is 1: 0.07, and sodium salt additive is made up of sodium chloride and sodium carbonate, chlorine The mass ratio of sodium chloride and sodium carbonate is 1: 1.5;

[0064] (b) Perform pre-oxidation treatment on the mixed material under the conditions of 0.4r / min rotary turning and 0.5Mpa air injection to obtain the pre-oxidation material, wherein the p...

Embodiment 2

[0068] Present embodiment is a kind of method that takes vanadium concentrate slag as raw material to prepare sodium vanadate, and this method comprises the steps:

[0069] (a) Dry and grind the vanadium slag until the particle size is not less than 120 mesh, and remove the metallic iron through the automatic continuous dry electromagnetic iron remover to obtain the vanadium slag material, and then mix the vanadium slag material with the sodium salt additive , obtain mixed material, wherein, the content of MFe is 4.28% in the vanadium fine slag material, and the mass ratio of vanadium fine slag material and sodium salt additive is 1: 0.3, and sodium salt additive is made up of sodium chloride and sodium carbonate, chlorine The mass ratio of sodium chloride and sodium carbonate is 1: 2;

[0070](b) Perform pre-oxidation treatment on the mixed material under the conditions of 1.2r / min rotary turning and 1.6Mpa blowing air to obtain pre-oxidation material, wherein the pre-oxidati...

Embodiment 3

[0074] Present embodiment is a kind of method that takes vanadium concentrate slag as raw material to prepare sodium vanadate, and this method comprises the steps:

[0075] (a) Dry and grind the vanadium slag until the particle size is not less than 120 mesh, and remove the metallic iron through the automatic continuous dry electromagnetic iron remover to obtain the vanadium slag material, and then mix the vanadium slag material with the sodium salt additive , obtain mixed material, wherein, the content of MFe is 4.43% in the vanadium fine slag material, and the mass ratio of vanadium fine slag material and sodium salt additive is 1: 0.1, and sodium salt additive is made up of sodium chloride and sodium carbonate, chlorine The mass ratio of sodium chloride and sodium carbonate is 1: 1.8;

[0076] (b) Perform pre-oxidation treatment on the mixed material under the conditions of 1r / min rotary turning and 1.0Mpa air injection to obtain pre-oxidized material, wherein the pre-oxidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com