Flash super-wear-resistant diamond glaze, ceramic tile and preparation method thereof

A super wear-resistant, diamond glaze technology, applied in the field of building ceramic materials, can solve the problems of unsustainable anti-fouling property, affecting the anti-fouling property of bricks, etc., and achieve the effect of improving the flashing effect, good flashing effect and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

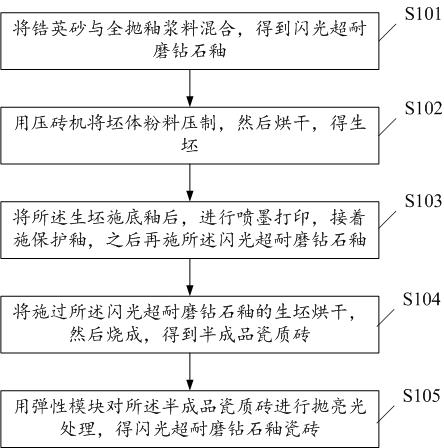

[0086] Corresponding, such as figure 1 , The present invention also provides a flash superabrasive diamond glazed tile production method, comprising:

[0087] S101, the zircon enamel paste is mixed with the whole cast, get flash super wear-resistant diamond enamel;

[0088] S102, pressed powder body with the brick press, and then dried to obtain a green body;

[0089] S103, after the end of the green enamel is applied, ink jet printing, followed by protection of the glaze is applied, then reapplied to the flash superabrasive diamond enamel;

[0090] S104, be administered through the flash drying green diamond superabrasive glaze, and then fired to obtain a semi-finished ceramic tile;

[0091] S105, processing for throwing light on the semifinished ceramic tile module with an elastic, wear-resistant diamond flash obtain glazed ceramic tile.

[0092] Specifically, the step S101 comprises:

[0093] The chemical composition of the whole cast glaze slurry in a ball mill related materia...

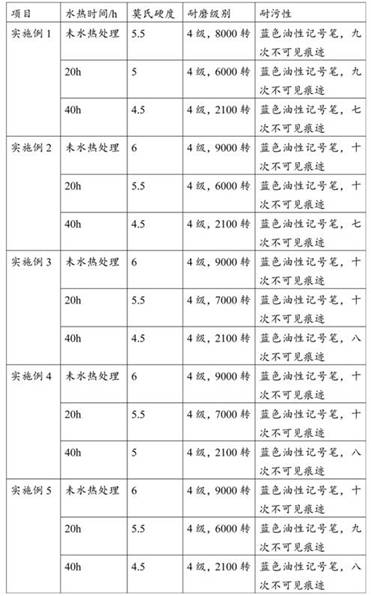

Embodiment 1

[0111] 1) with potassium sodium feldspar, quartz powder, talc burning, barium carbonate, strontium carbonate, zinc oxide, wollastonite, corundum, dolomite, diopside, zircon sand, water reducer and water and other raw materials according to the chemical quality ingredients are:

[0112] SiO 2 + Al 2 O 3 = 71.9wt%, CaO + MgO + ZnO + BaO + SrO = 25wt%, Na 2 O + K 2 O = 1.9wt%, P 2 O 5 = 1.0wt%, ZrO 2 = 0.2wt%, SiO 2 / Al 2 O 3 Ratio = 1.8, was weighed into a ball mill for milling. 10 hours after milling to a fineness of 0.7%.

[0113] 2) the object 60 to 130 zircon sand in a 1: 9 mass ratio of the glaze is mixed with the whole cast slurry, followed by addition of 0.6% aqueous polyurethane, fully stirred, to obtain a flash superabrasive diamond enamel;

[0114] 3) Press for the porcelain powder pressed into a green body, dried and then sent to kiln drying at 200 degrees, to obtain a green ceramic tile;

[0115] 4) After administered after drying the green body porcelain enamel substra...

Embodiment 2

[0119] 1) with potassium sodium feldspar, quartz powder, talc burning, barium carbonate, strontium carbonate, zinc oxide, wollastonite, corundum, dolomite, diopside, zircon sand, water reducer and water and other raw materials according to the chemical quality ingredients are:

[0120] SiO 2 + Al 2 O 3 = 76wt%, CaO + MgO + ZnO + BaO + SrO = 20wt%, Na 2 O + K 2 O = 2.2wt%, P 2 O 5 = 1.55wt%, ZrO 2 = 0.25wt%, SiO 2 / Al 2 O 3 Ratio = 1.5, was weighed into a ball mill for milling. 9 hours after milling to a fineness of 0.75%.

[0121] 2) 70 ~ 160 mesh zircon sand mixed with a mass ratio of 1:12 according to the full glaze polishing slurry, followed by addition of 0.7% aqueous polyurethane, fully stirred, to obtain a flash superabrasive diamond enamel;

[0122] 3) Press for the porcelain powder pressed into a green body, dried and then sent to kiln drying at 190 degrees, to obtain a green ceramic tile;

[0123] 4) After administered after drying the green body porcelain enamel substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com