Impact-resistant antistatic polyethylene material and preparation method thereof

An antistatic and polyethylene technology, which is applied in the field of impact-resistant and antistatic polyethylene materials and its preparation, can solve the problems of unusable, high viscosity of heavy oil, sticking and clogging, etc., and achieve prolonging service life, convenient manufacturing process and stable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

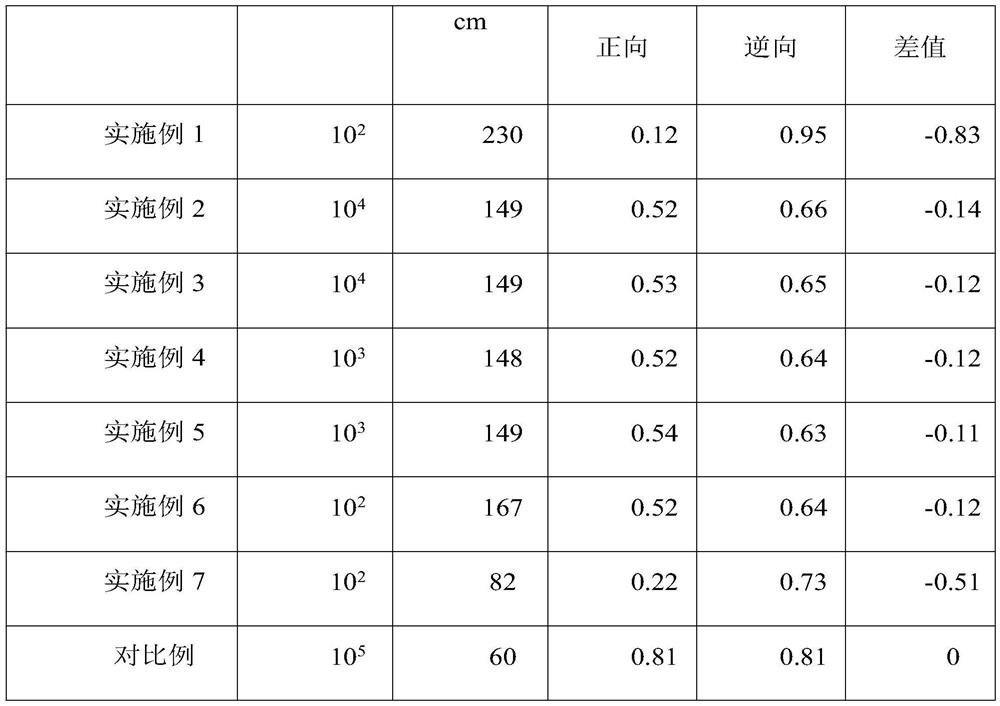

Examples

Embodiment 1

[0034] An impact-resistant and antistatic polyethylene material mainly includes the following raw material components in parts by weight: 25 parts of metal-coated glass fiber and 75 parts of modified high-density polyethylene emulsion.

[0035] A method for preparing an impact-resistant and antistatic polyethylene material mainly includes the following preparation steps:

[0036] (1) Coarsening the ultrafine glass fibers to obtain a coarsened glass fiber solution;

[0037] (2) Mix the 10g / L titanium dioxide aqueous solution and the roughened glass fiber solution at a volume ratio of 1:1 to obtain a mixed solution, then add 0.125g / L palladium chloride aqueous solution that is 40 times the volume of the mixed solution, Mix evenly to obtain the sensitized glass fiber solution;

[0038] (3) Separating the layered niobate powder between layers to obtain a niobate film;

[0039] (4) mixing the niobate film and the sensitized glass fiber solution to obtain a metal-coated glass fibe...

Embodiment 2

[0048] An impact-resistant and antistatic polyethylene material mainly includes the following raw material components in parts by weight: 25 parts of metal-coated glass fiber and 75 parts of modified high-density polyethylene emulsion.

[0049] A method for preparing an impact-resistant and antistatic polyethylene material mainly includes the following preparation steps:

[0050] (1) Mix 10g / L titanium trioxide aqueous solution and glass fiber solution at a volume ratio of 1:1 to obtain a mixed solution, then add 0.125g / L palladium chloride aqueous solution that is 40 times the volume of the mixed solution, and mix evenly. Obtain sensitized glass fiber solution;

[0051] (2) Separating the layered niobate powder between layers to obtain a niobate film;

[0052] (3) mixing the niobate film and the sensitized glass fiber solution to obtain a metal-coated glass fiber solution, and leaving the metal-coated glass fiber solution at room temperature for 12 hours to obtain a metal-co...

Embodiment 3

[0061] An impact-resistant and antistatic polyethylene material mainly includes the following raw material components in parts by weight: 25 parts of metal-coated glass fiber and 75 parts of modified high-density polyethylene emulsion.

[0062] A method for preparing an impact-resistant and antistatic polyethylene material mainly includes the following preparation steps:

[0063] (1) Coarsening the ultrafine glass fibers to obtain a coarsened glass fiber solution;

[0064] (2) Separating the layered niobate powder between layers to obtain a niobate film;

[0065] (3) mixing the niobate film and the roughened glass fiber solution to obtain a metal-coated glass fiber solution, and leaving the metal-coated glass fiber solution at room temperature for 12 hours to obtain a metal-coated glass fiber;

[0066] (4) prepare modified high-density polyethylene emulsion;

[0067] (5) Mix the metal-coated glass fiber and the modified high-density polyethylene emulsion evenly, place it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com