Acrylic acid high-elastic waterproof coating for metal roofs and preparation method thereof

An acrylic high-elastic and waterproof coating technology, applied in the direction of reflection/signal coating, coating, etc., can solve the problems of poor ventilation effect, poor light reflection ability and heat insulation ability of waterproof coating film, unfavorable health and other problems, and achieve good water resistance performance, good light reflection and heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

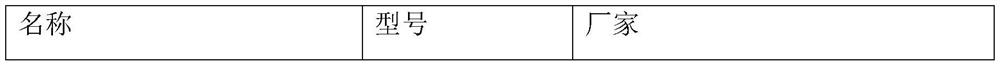

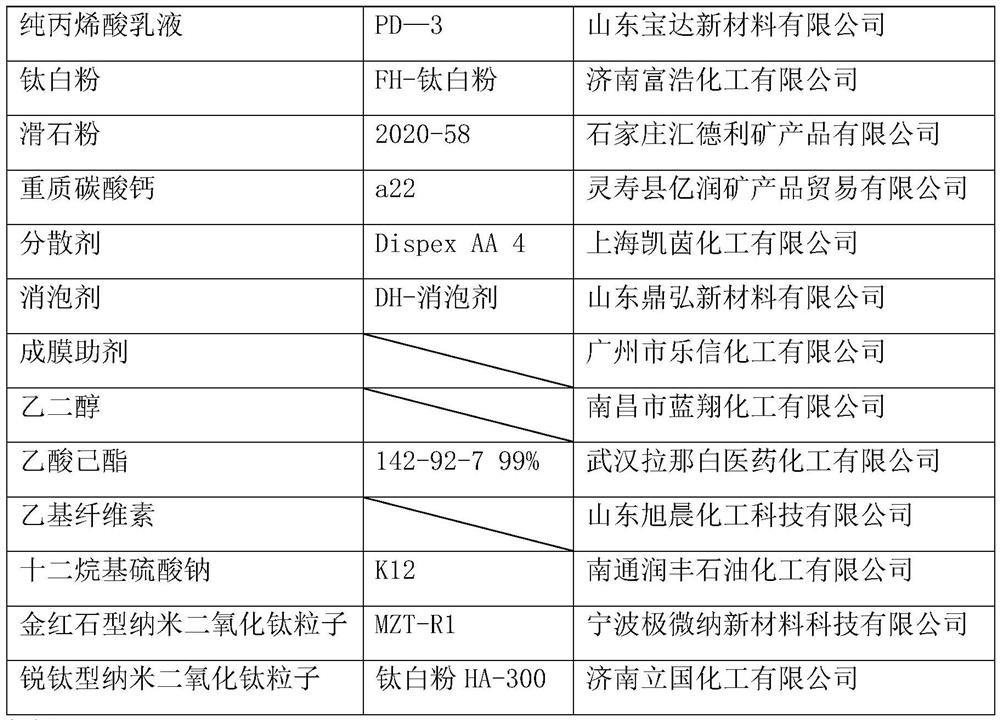

Image

Examples

preparation example 1

[0034] The thermal insulation filler titanium dioxide / ethyl cellulose composite porous microsphere material is prepared by the following method:

[0035] S1, adding ethyl cellulose to hexyl acetate, stirring evenly, then adding nano-titanium dioxide particles (selected from rutile nano-titanium dioxide particles) and stirring evenly; S2, adding sodium lauryl sulfate to ethyl acetate saturated in the aqueous solution and stirred evenly; S3, the solution obtained from S1 was added to the solution obtained from S2 and stirred uniformly; S4, the solution obtained from S3 was added to the deionized aqueous solution of sodium lauryl sulfate and stirred uniformly; S5, The solution obtained in S4 was vacuum filtered to collect the powder and dried; wherein the weight ratio of nano-titanium dioxide particles to ethyl cellulose was 1:2.

preparation example 2

[0037] The difference from Preparation Example 1 is that the weight ratio of nano-titanium dioxide particles to ethyl cellulose is 1:3.

preparation example 3

[0039] The difference from Preparation Example 1 is that the weight ratio of nano-titanium dioxide particles to ethyl cellulose is 1:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com