Alkali gelatinized wet glue as well as preparation method and application thereof

A gelatinization and wet glue technology, which is applied in the direction of starch-derived adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of high cost, poor thermal gelatinization of wet glue, and easy edge warping of wall coverings and other problems, to achieve the effect of high adhesion, good performance, and not easy to warp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

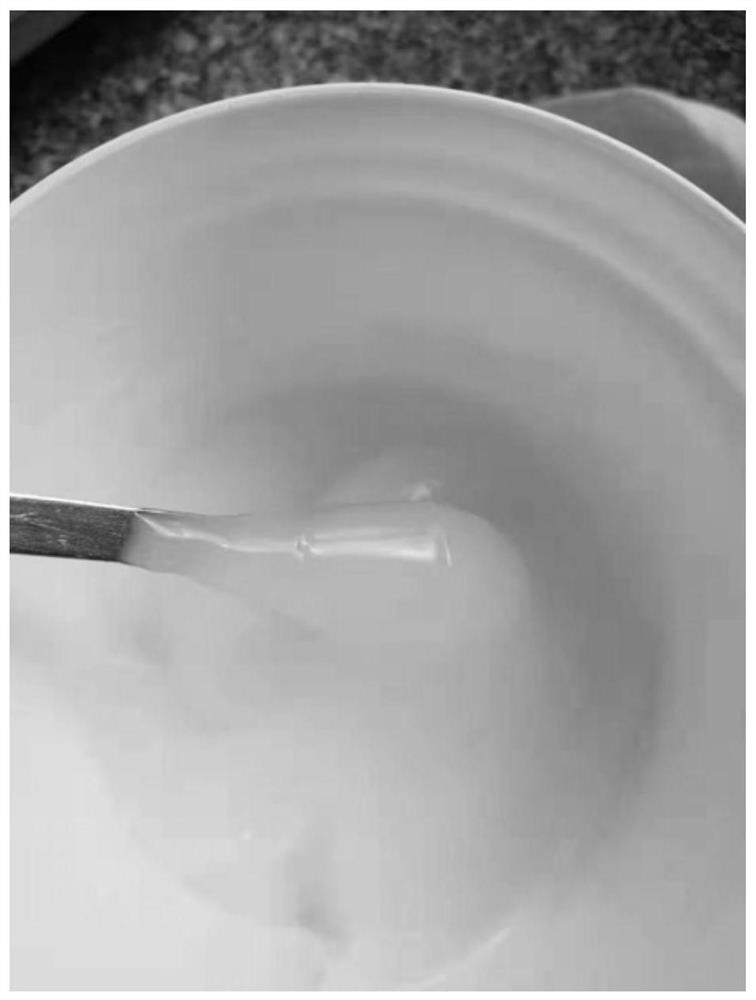

Image

Examples

preparation example Construction

[0071] According to an embodiment of the present invention, the preparation method of the alkali-gelatinized wet glue comprises the following steps:

[0072] Step 1. Add acetylated starch into water, add water-soluble inorganic salt, and stir to obtain dispersed materials;

[0073] Step 2, adding part of the alkaline gelatinizer to the dispersed material and stirring to obtain the pregelatinized dispersed material;

[0074] Step 3, adding hydroxypropyl distarch phosphate to the pregelatinized dispersed material, adding the remaining alkaline gelatinizer, and stirring to obtain the gelatinized material;

[0075] Step 4, adding an acid neutralizer to the gelatinized material, adjusting the pH, adding an auxiliary agent, and stirring to obtain the alkali gelatinized wet glue of the present invention.

[0076] In order to disperse or dissolve the added raw material components in the material system more easily, the raw material components to be added can be pre-dispersed or disso...

Embodiment 1

[0090] In this example, the alkali gelatinized wet glue is made by using an alkaline gelatinizer under certain conditions, and a variety of modified starches are made through an alkali gelatinization process, wherein the alkali gelatinized wet glue is made of the following raw materials in parts by weight Components made:

[0091] 7 parts of acetylated starch, 16 parts of hydroxypropyl distarch phosphate, 5 parts of water-soluble inorganic salt, 1.5 parts of alkaline gelatinizer, 1.7 parts of acid neutralizer, 0.5 part of whitening agent, 0.3 part of humectant, 0.1 parts of freezing agent, 1.4 parts of anti-corrosion and anti-mold agent, and 66.5 parts of water. Among them, the water-soluble inorganic salt is sodium chloride; the alkaline pasting agent is sodium hydroxide; the acid neutralizing agent is hydrochloric acid; the whitening agent is titanium dioxide; the moisturizing agent is glycerin; Mixture; antiseptic antifungal agent is a mixture of sodium diacetate and Katho...

Embodiment 2

[0098] In this example, the alkali gelatinized wet glue is made by using an alkaline gelatinizer under certain conditions, and a variety of modified starches are made through an alkali gelatinization process, wherein the alkali gelatinized wet glue is made of the following raw materials in parts by weight Components made:

[0099]13 parts of acetylated starch, 7 parts of hydroxypropyl distarch phosphate, 5 parts of water-soluble inorganic salt, 1.0 part of alkaline gelatinizer, 1.2 parts of acid neutralizer, 0.5 part of whitening agent, 0.5 part of humectant, 0.1 parts of freezing agent, 1.0 parts of anti-corrosion and anti-mold agent, and 70.7 parts of water. Wherein, the water-soluble inorganic salt is sodium chloride; the alkaline gelatinizer is calcium hydroxide; the acid neutralizer is oxalic acid; the whitening agent is talcum powder; the humectant is carboxymethyl modified starch; the antifreeze agent is propylene glycol; The antiseptic and antifungal agent is organosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com