Lithium vanadium fluorophosphate silicate positive electrode material and preparation method thereof

A technology of lithium vanadium silicate and positive electrode materials, which is applied in the direction of fluosilicic acid, positive electrodes, lithium batteries, etc., to achieve the effects of excellent rate, low cost, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

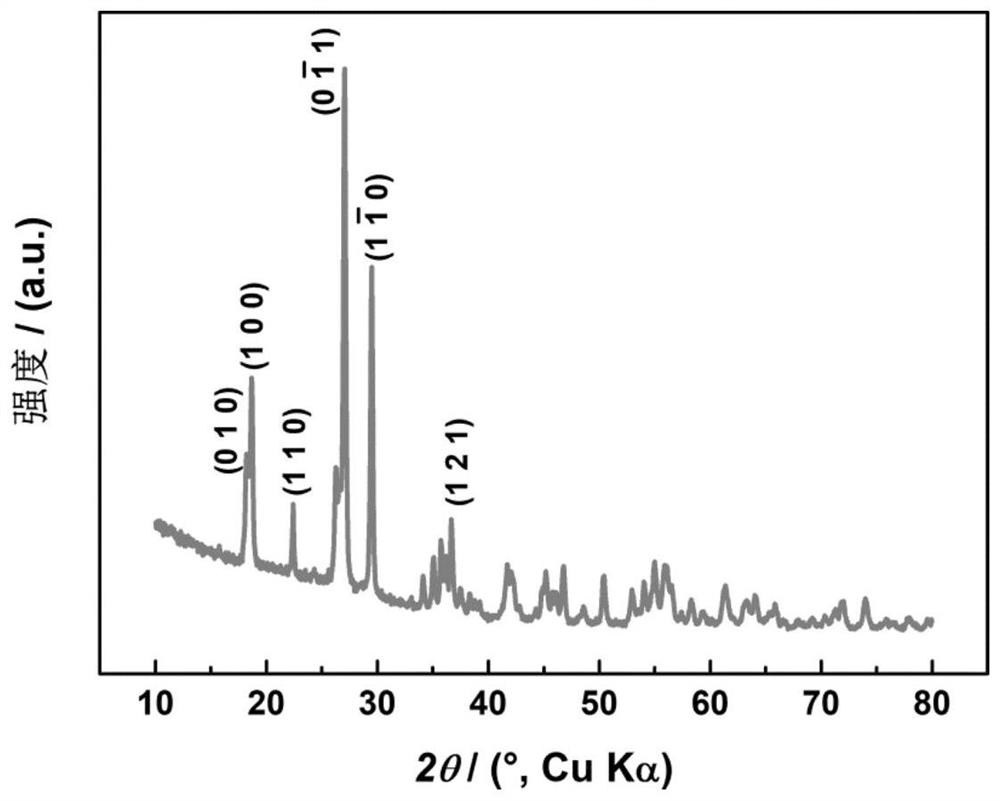

[0028] This embodiment is a lithium vanadium fluorophosphosilicate positive electrode material, and its chemical formula is: LiVP 0.9 Si0.1 o 4 F, the specific preparation method comprises the following steps:

[0029] 1. Weigh the vanadium source, silicon source, phosphorus source and carbon source according to the molar ratio of 1:0.1:0.9:1.05, use absolute ethanol as the dispersant, ball mill, disperse and mix in a ball mill for 12 hours.

[0030] 2. Place the ball-milled mixture in an oven to dry, grind, press into tablets, and sinter at 700°C for 6 hours in an inert atmosphere.

[0031] 3. The product after sintering is weighed with the lithium source according to the ratio of 1:1.02 in molar ratio, and then adding a carbon source and a fluorine source with a mass ratio of 6% and 20% respectively, with dehydrated alcohol as a dispersant, in Mill, disperse and mix in a ball mill for 18 hours.

[0032] 4. Dry the mixture in an oven, grind, press into tablets, and sinter ...

Embodiment 2

[0045] This embodiment is a lithium vanadium fluorophosphosilicate positive electrode material, and its chemical formula is: LiVP 0.8 Si 0.2 o 4 F, the specific preparation method comprises the following steps:

[0046] 1. Weigh the vanadium source, silicon source, phosphorus source and carbon source according to the molar ratio of 1:0.2:0.8:0.9, use absolute ethanol as the dispersant, ball mill, disperse and mix in a ball mill for 12 hours.

[0047] 2. Place the ball-milled mixture in an oven to dry, grind, press into tablets, and sinter at 750°C for 4 hours in an inert atmosphere.

[0048] 3. The product after sintering is weighed according to the molar ratio of 1:1.04 with the lithium source, and the carbon source and the fluorine source are added with a mass ratio of 15% and 10%, respectively, and dehydrated alcohol is used as a dispersant. Mill, disperse and mix in a ball mill for 18 hours.

[0049] 4. Dry the mixture in an oven, grind, press into tablets, and sinter ...

Embodiment 3

[0060] This embodiment is a lithium vanadium fluorophosphosilicate positive electrode material, and its chemical formula is: LiVP 0.6 Si 0.4 o 4 F, the specific preparation method comprises the following steps:

[0061] 1. Weigh the vanadium source, silicon source, phosphorus source and carbon source according to the molar ratio of 1:0.4:0.6:1, and use the mixture of absolute ethanol and deionized water according to the volume ratio of 7:3 as the dispersant, Ball mill, disperse and mix in a ball mill for 12 hours.

[0062] 2. Place the ball-milled mixture in an oven to dry, grind, press into tablets, and sinter at 700°C for 6 hours in an inert atmosphere.

[0063] 3. Weigh the sintered product with lithium source and fluorine source according to the molar ratio of 1:1:1, then add carbon source and fluorine source with mass ratio of 20% and 2% respectively, and use absolute ethanol The mixture of deionized water and deionized water according to the volume ratio of 7:3 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com