Intelligent spraying vehicle system for circumferential spraying in beam field and operation method

A technology for spraying vehicles and vehicle-mounted control systems, which is applied in the field of beam-field circumferential spraying intelligent spraying vehicle systems, can solve problems such as low scalability, limited maintenance area, and no data interface, and achieves both system performance and Cost, prospect of wide application and promotion, effect of high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

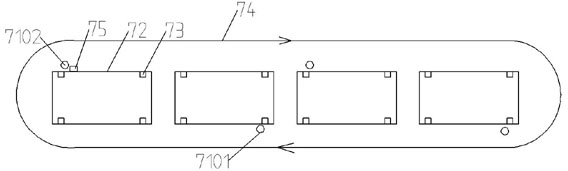

[0087] Embodiment 1, taking the maintenance of four prefabricated beams in one maintenance cycle as an example, this scheme is explained:

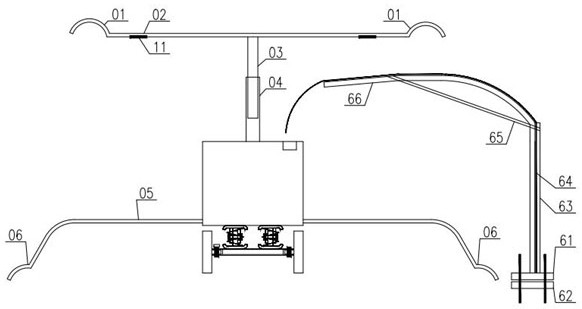

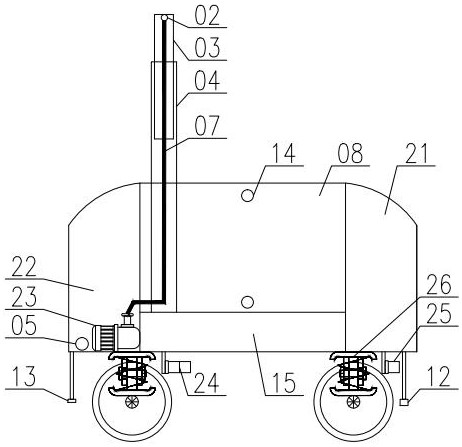

[0088] An intelligent spray vehicle system for circumferential spraying of a beam field. The beam field includes four prefabricated beams 72, and the four prefabricated beams 72 are arranged side by side at intervals. It also includes an intelligent spray vehicle and a host computer. The host computer It includes a computer integrated with embedded programs, and the computer and the vehicle-mounted control system of the intelligent spraying vehicle are integrated and controlled through information fusion, wherein the screen of the computer is a touch screen. The beam field circumferential spraying intelligent spraying vehicle system includes:

[0089] Communication system, the communication system includes more than one wireless data transmission station based on Ethernet, the wireless data transmission station communicates with the compute...

Embodiment 2

[0108] Embodiment two, such as Figure 8 as shown,

[0109] According to the first aspect of the disclosed embodiments of the present invention, there is provided a manual operation method suitable for the above-mentioned beam field circumferential spray intelligent spray vehicle system, the manual operation method includes:

[0110] Step S01: Select the control mode of the intelligent spray vehicle, wherein,

[0111] Step S01.1: Power on and scan;

[0112] Step S01.2: manual / automatic control mode selection;

[0113] Step S02: The intelligent spray vehicle is switched to manual control operation;

[0114] Step S03: start the motion control device;

[0115] Step S04: Enter the manual single-item control operation mode;

[0116] Step S05: single item debugging, it should be further pointed out that single item debugging includes:

[0117] Running along the magnetic force line; water injection; charging; arm opening and closing; steering, the above individual adjustments a...

Embodiment 3

[0120] Embodiment three, such as Figure 9 Shown:

[0121] According to the first aspect of the disclosed embodiments of the present invention, there is provided an automatic operation method suitable for the above-mentioned beam field circumferential spraying intelligent spraying vehicle system, wherein the priority of the liquid level detection of the low liquid level sensor is higher than that of the infrared distance The priority of the sensor detection, when the beam and the low water level are detected at the same time, the water will be injected and charged at the same time; the priority of the detection of the water injection point system is higher than the priority of the low water level detection of the low liquid level sensor. When it reaches the water injection point system, Regardless of whether it is at a low water level, priority is given to filling water and charging at the same time:

[0122] The automated work methods include:

[0123] Step S01: Select the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com