POE (Polyolefin Elastomer) material-based high-weather-resistance photovoltaic adhesive film preparation process

A preparation process and weather resistance technology, which is applied in the field of photovoltaic adhesive film preparation process, can solve the problems of panel corrosion damage, lack of breathable and waterproof ability of the base layer, lack of water permeable protection ability of the base layer, etc., to avoid corrosion, improve the overall weather resistance, and enhance the resistance The effect of impact power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

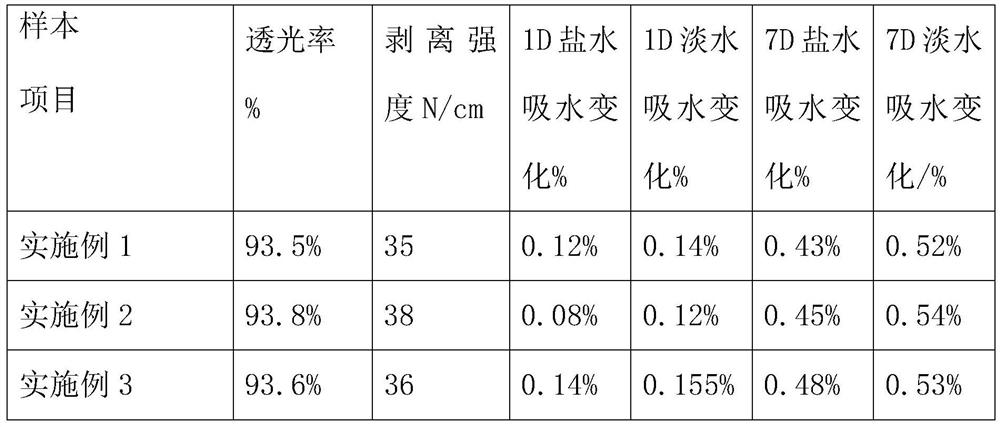

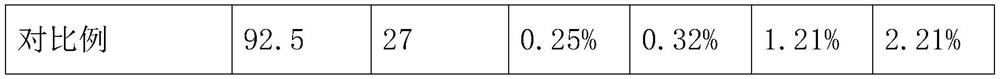

Examples

Embodiment 1

[0033] The present invention provides a technical solution: a preparation process based on the POE material is strongly resistant, and specifically includes the steps of:

[0034] S1, feedstock prefabrication, a plurality of master bbs in the first substrate, the second substrate, and the third substrate are placed in a dryer for 20 minutes, and the moisture in the master bump in each of the matrix is removed.

[0035] S2, raw material weighing, according to the equipped equivalent, the first substrate, the second substrate, and the third substrate, weigh the cross-linking agent of the corresponding formation amount of the first substrate, the second substrate, and the third substrate. Adhesive, anti-aging additives and a certain amount of water;

[0036] S3, the mixed extrusion, the first substrate, the second substrate, and the third substrate, respectively, inserted into the multilayer coextrusion equipment, respectively, the outer layer, the inner layer, and the core layer d...

Embodiment 2

[0045] Unlike Example 1, the present invention also provides a highly weather-based photovoltaic material POE film manufacturing process, comprises the steps of:

[0046] S1, feedstock prefabrication, a plurality of master bbs in the first substrate, the second substrate, and the third substrate are placed in a dryer for 20 minutes, and the moisture in the master bump in each of the matrix is removed.

[0047] S2, raw material weighing, according to the equipped equivalent, the first substrate, the second substrate, and the third substrate, weigh the cross-linking agent of the corresponding formation amount of the first substrate, the second substrate, and the third substrate. Adhesive, anti-aging additives and a certain amount of water;

[0048] S3, the mixed extrusion, the first substrate, the second substrate, and the third substrate, respectively, inserted into the multilayer coextrusion equipment, respectively, the outer layer, the inner layer, and the core layer double scr...

Embodiment 3

[0057] Unlike Examples 1-2, the present invention also discloses a photovoltaic film preparation process based on the POE material, and specifically includes the following steps:

[0058] S1, feedstock prefabrication, a plurality of master bbs in the first substrate, the second substrate, and the third substrate are placed in a dryer for 20 minutes, and the moisture in the master bump in each of the matrix is removed.

[0059] S2, raw material weighing, according to the equipped equivalent, the first substrate, the second substrate, and the third substrate, weigh the cross-linking agent of the corresponding formation amount of the first substrate, the second substrate, and the third substrate. Adhesive, anti-aging additives and a certain amount of water;

[0060] S3, the mixed extrusion, the first substrate, the second substrate, and the third substrate, respectively, inserted into the multilayer coextrusion equipment, respectively, the outer layer, the inner layer, and the core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com