Pretreatment system and pretreatment method for oily sludge

A pretreatment and oily sludge technology, applied in sludge treatment, water/sludge/sewage treatment, centrifuged water/sewage treatment, etc., can solve the pollution caused by oily sludge incineration, which is difficult to meet the national environmental protection standards, Problems such as excessive oil content in oily sludge are beneficial to harmless treatment, solving environmental pollution and transportation permits, and using less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

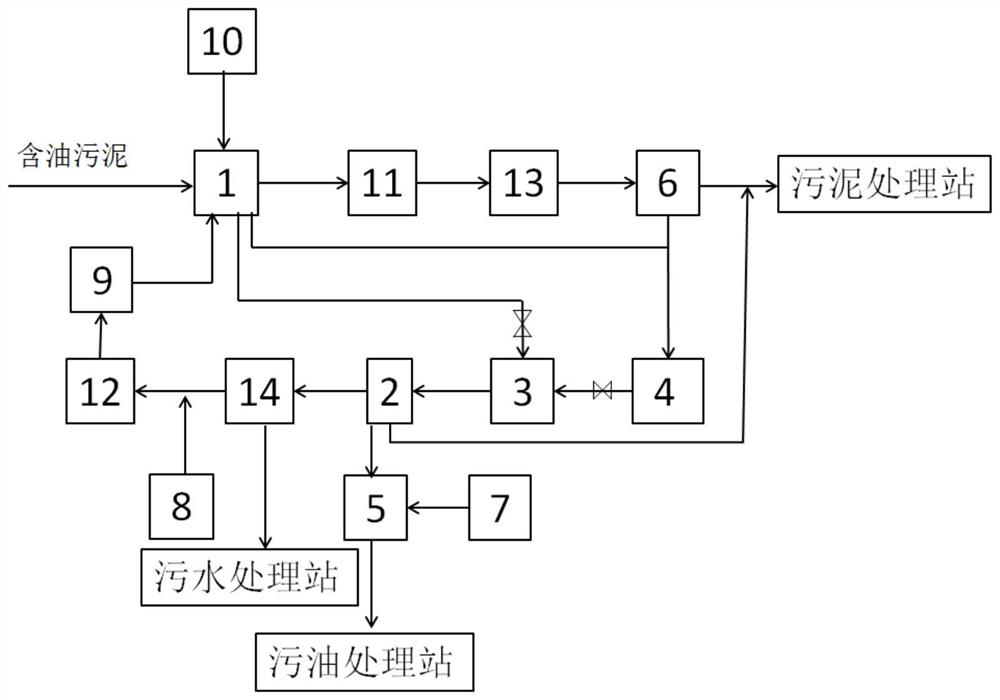

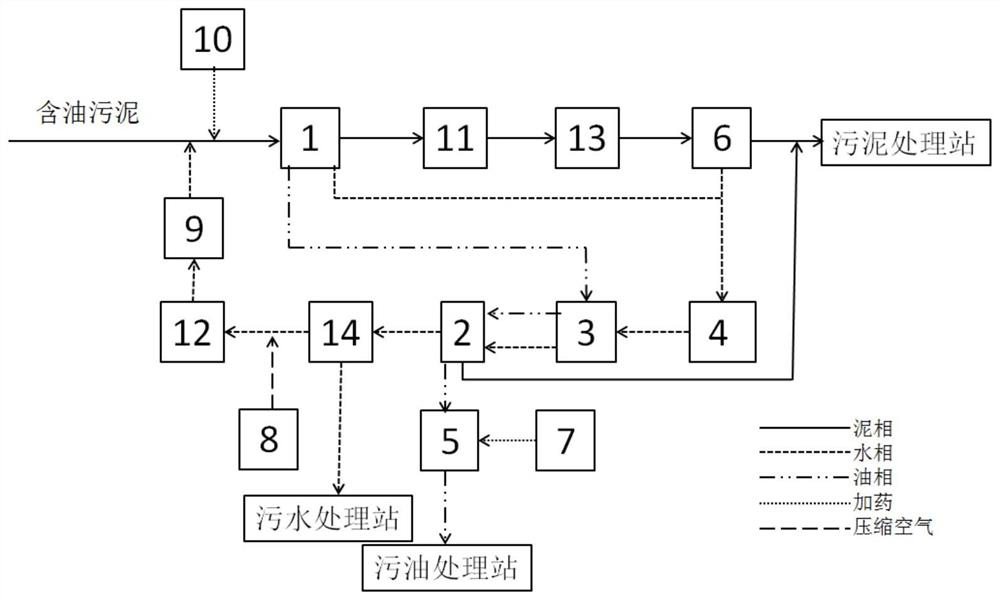

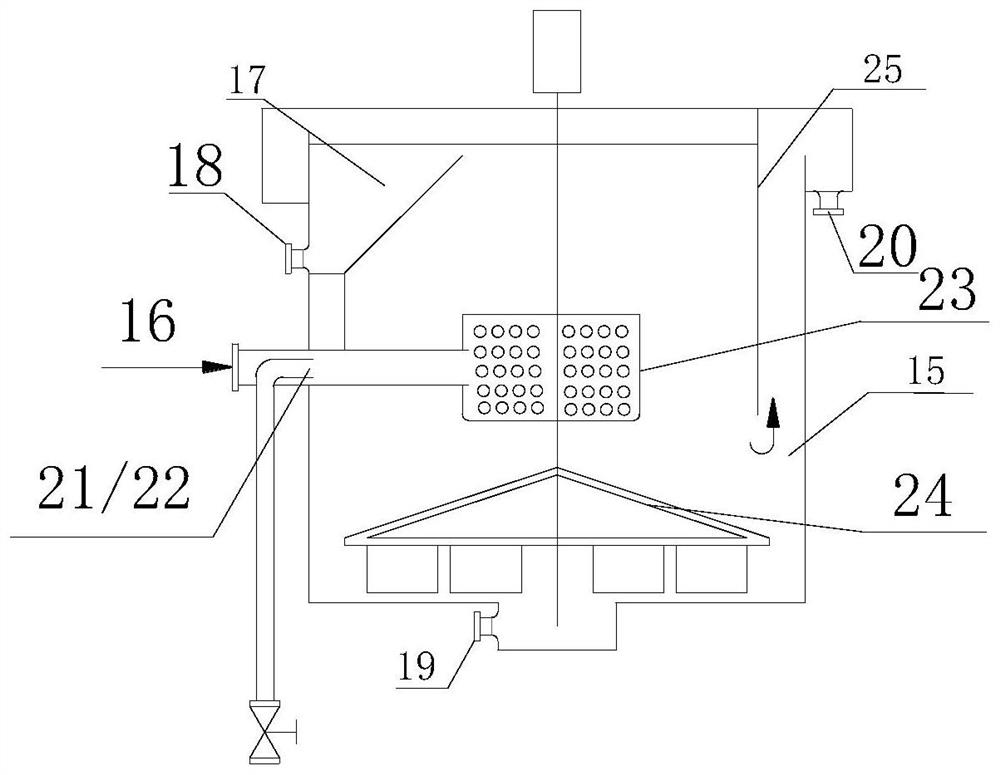

[0057] The present invention is directed to production of large oily sludge prior processing system immature problems and to provide a pretreatment system, comprising oily sludge pre-processing means, three-phase Decanter centrifuge sump oil, a two-phase Decanter Centrifuge machine, water recovery tank, the recovery tank sludge, dosing devices, an air compressor and a dissolved gas tank pressure, the main lift pumps processing apparatus, together with ancillary equipment like valves and metering devices, the formation of a skid-mounted movable oily sludge pre-treatment system, oilfield production needs.

[0058] Pretreatment system of the present invention and the pretreatment method works as follows: first of oily sludge to use pre-processing means "air flotation mainly degreasing, washing and settling supplement" oil, water, mud three phases fluidized, settlement and washing, removal of a large amount of oily sludge waste oil, waste oil obtained, and sewage sludge; sludge treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com