Preparation method of narrow-particle-size polyvinyl acetate embolization microspheres with controllable drug loading performance

A technology of polyvinyl acetate embolization microspheres and vinyl acetate, which is applied in medical science, surgery, surgical adhesives, etc., can solve the problems of low drug loading, complex structure, and high preparation cost of Callisphere, and achieve a wide range of applicable drugs , The preparation process is simple, the drug loading effect is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

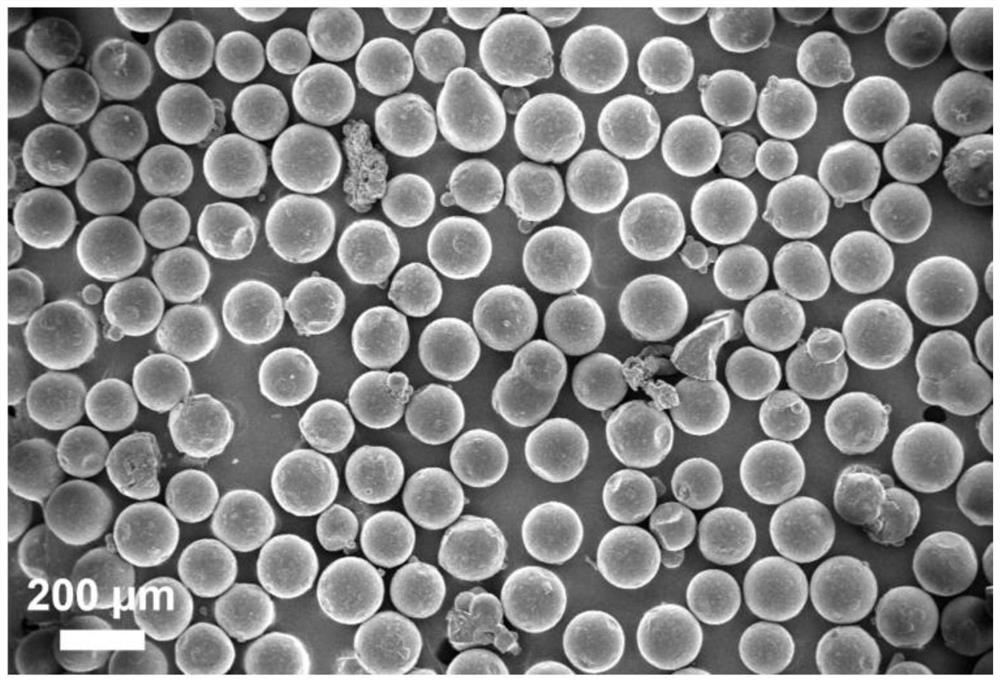

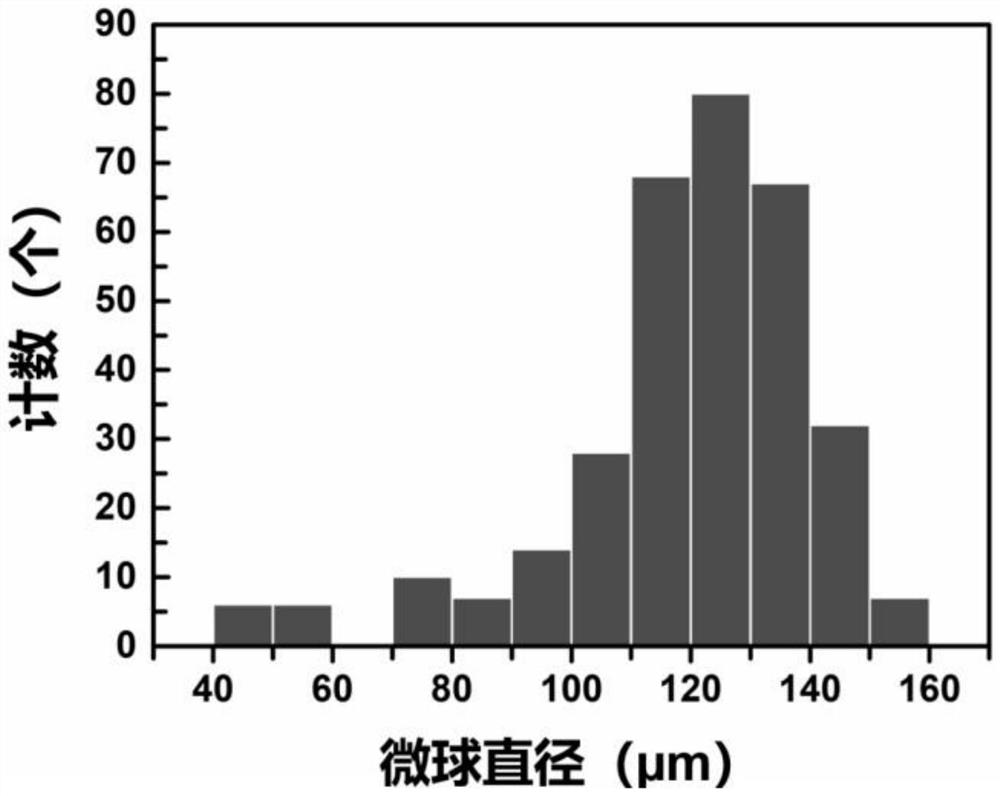

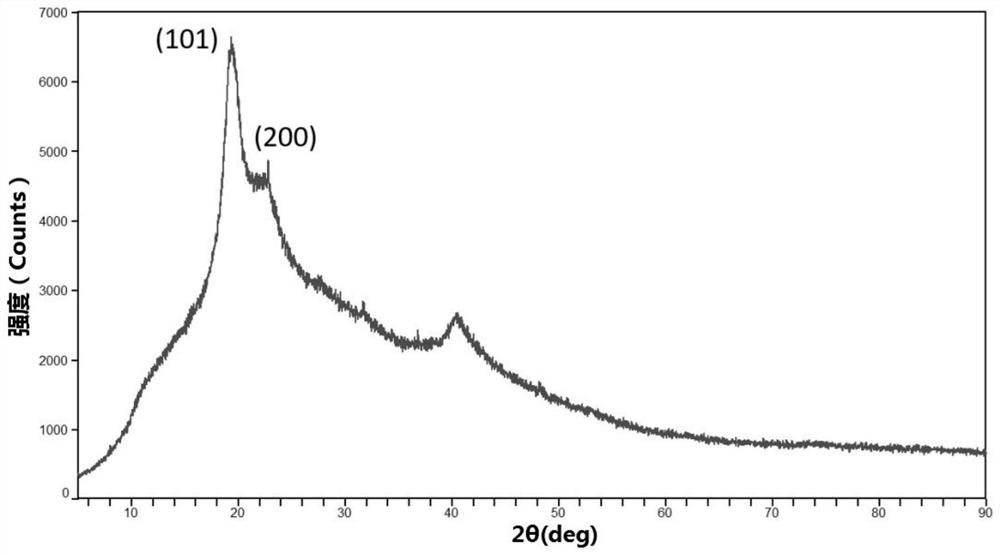

[0038] Synthesis of embodiment 1 polyvinyl acetate embolic microspheres

[0039] (1) Put 100 mL of deionized water into a 250 mL three-necked flask connected with a condensing reflux device. Under nitrogen protection, 0.5 g of polyvinylpyrrolidone (molecular weight = 29000) was dissolved in 100 mL of deionized water in a three-necked flask under magnetic stirring (stirring speed: 300-350 rpm).

[0040](2) 0.134g of azobisisobutyronitrile (AIBN) was stirred and dissolved in 50mL of vinyl acetate (VAc), and the temperature of the solution in the three-necked flask was heated to 65°C. Then slowly pour the VAc monomer dissolved with AIBN into a three-necked flask, and raise the temperature of the solution to 70°C for two hours, and then raise the temperature of the solution to 75°C for two hours; during the reaction, keep Nitrogen was bubbled continuously (the nitrogen outlet was extended from the conduit to the bottom of the reaction solution).

[0041] (3) After the reaction w...

Embodiment 2

[0042] Synthesis of embodiment 2 polyvinyl acetate embolic microspheres

[0043] (1) Put 100 mL of deionized water into a 250 mL three-necked flask connected with a condensing reflux device. Under nitrogen protection, 1.5 g of polyvinyl alcohol 1788 was dissolved in 100 mL of deionized water in a three-necked flask under magnetic stirring (stirring speed: 300-350 rpm).

[0044] (2) 0.2 g of dibenzoyl peroxide (BPO) was stirred and dissolved in 50 mL of vinyl acetate (VAc), and the temperature of the solution in the three-necked flask was heated to 65° C. Then the VAc monomer dissolved with BPO was slowly poured into a three-necked flask, and the temperature of the solution was raised to 70° C. for two hours. Afterwards, the temperature of the solution was raised to 75° C. for two hours.

[0045] (3) After the reaction was finished, the three-necked flask was placed in room temperature and cooled slowly. After the cooling was finished, the reactant in the bottle was transfer...

Embodiment 3

[0046] Synthesis of embodiment 3 polyvinyl acetate embolic microspheres

[0047] (1) Put 100 mL of deionized water into a 250 mL three-necked flask connected with a condensing reflux device. Under nitrogen protection, 2.0 g of polyvinyl alcohol 1788 was dissolved in 100 mL of deionized water in a three-necked flask under magnetic stirring (stirring speed: 300-350 rpm).

[0048] (2) 0.134g of azobisisobutyronitrile (AIBN) was stirred and dissolved in 50mL of vinyl acetate (VAc), and the temperature of the solution in the three-necked flask was heated to 65°C. Then the VAc monomer dissolved with AIBN was slowly poured into a three-necked flask, and the temperature of the solution was raised to 70° C. for two hours. Afterwards, the temperature of the solution was raised to 75° C. for two hours.

[0049] (3) After the reaction was finished, the three-necked flask was placed in room temperature and cooled slowly. After the cooling was finished, the reactant in the bottle was tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com