Sugammadex sodium freeze-dried powder injection and preparation method thereof

A technology of sugammadex sodium and freeze-dried powder injection, which is applied in the field of medicine, can solve the problems of high and low degradation impurities, and achieve the effects of high clarity, short reconstitution time and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

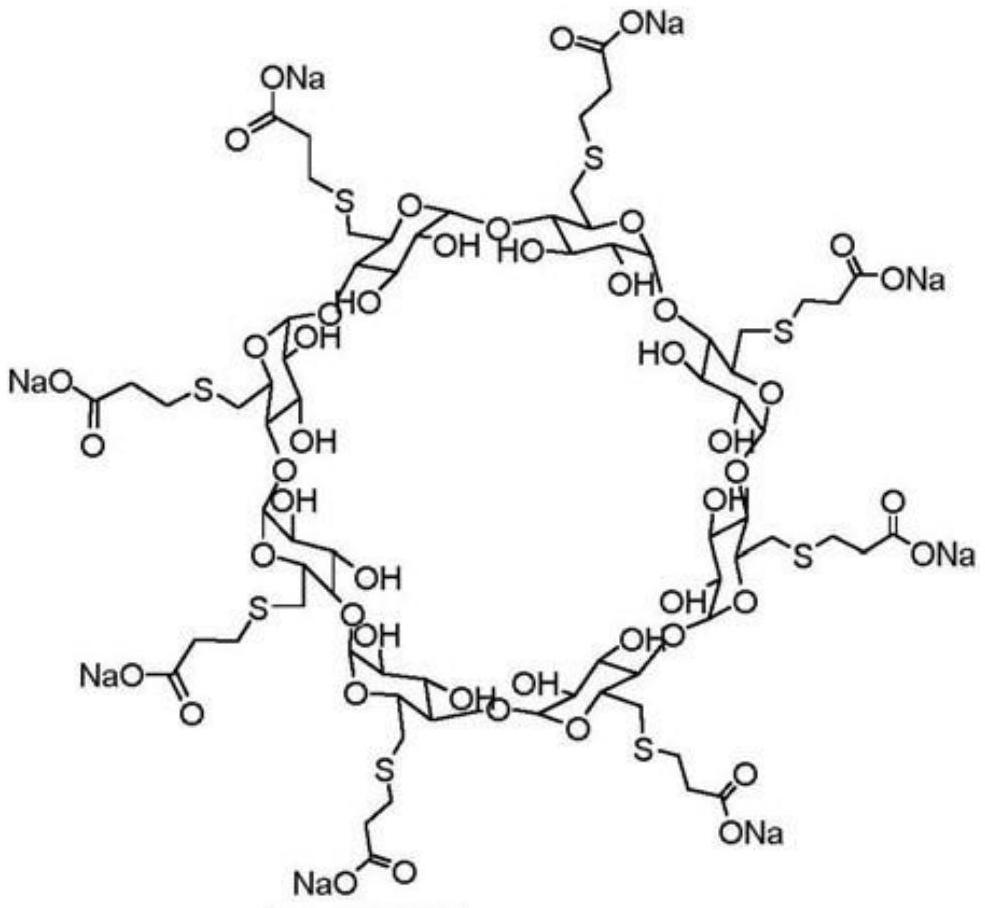

Image

Examples

Embodiment 1

[0026] prescription

[0027]

[0028] Accurately weigh 90% of the prescribed amount of water for injection; weigh the prescribed amount of sugammadex sodium and mannitol, slowly add to the water for injection, stir until dissolved, adjust the pH value to 7.50 with hydrochloric acid, stir for about 5 minutes, filter, The filtered filtrate is filled in vials at 5ml / bottle, and half-stoppered; the freeze dryer is cooled to -40°C in advance, and the filled samples are sent to the freeze-drying box, and the vacuum in the freeze-dryer is maintained at 0.15±0.02 mbar, keep it for 3h; keep the vacuum in the freeze dryer, raise the temperature of the shelf to -25°C at 0.5°C / h, and keep it warm for 5h; then raise the temperature of the shelf to -5°C at a rate of 1.5°C / h, and release the vacuum in the freeze dryer To standard atmospheric pressure, keep warm for 6 hours; vacuumize the freeze dryer and maintain 0.10±0.02mbar, then raise the shelf temperature to 20℃ at 2.0℃ / h, keep warm ...

Embodiment 2

[0030] prescription

[0031]

[0032] Accurately weigh 90% of the prescribed amount of water for injection; weigh the prescribed amount of sugammadex sodium and mannitol, slowly add to the water for injection, stir until dissolved, adjust the pH value to 7.47 with hydrochloric acid, stir for about 5 minutes, filter, The filtered filtrate is filled in vials at 5ml / bottle, and half-stoppered; the freeze dryer is cooled to -45°C in advance, and the filled samples are sent to the freeze-drying box, and the vacuum in the freeze-dryer is maintained at 0.15±0.02 mbar, keep it for 5h; the freeze dryer maintains vacuum, the shelf temperature rises to -20°C at 0.5°C / h, and keeps warm for 6h; the shelf temperature rises to -2°C at 1.5°C / h, and releases the vacuum in the freeze dryer To standard atmospheric pressure, keep warm for 6 hours; vacuumize the freeze dryer and maintain 0.10±0.02mbar, then raise the shelf temperature to 15℃ at 2.0℃ / h, keep warm for 8h; then raise the shelf tem...

Embodiment 3

[0034] prescription

[0035]

[0036] Accurately weigh 90% of the prescribed amount of water for injection; weigh the prescribed amount of sugammadex sodium and mannitol, slowly add to the water for injection, stir until dissolved, adjust the pH value to 7.51 with hydrochloric acid, stir for about 5 minutes, filter, The filtered filtrate is filled in vials at 5ml / bottle, and half-stoppered; the freeze dryer is cooled to -42°C in advance, and the filled samples are sent to the freeze-drying box, and the vacuum in the freeze-dryer is maintained at 0.15±0.02 mbar, keep for 4 hours; the freeze dryer maintains vacuum, the shelf temperature rises to -30°C at 0.5°C / h, and keeps warm for 5h; the shelf temperature rises to -8°C at 1.5°C / h, and releases the vacuum in the freeze dryer To standard atmospheric pressure, keep warm for 7 hours; vacuumize the freeze dryer and maintain 0.10±0.02mbar, then raise the shelf temperature to 25℃ at 2.0℃ / h, keep warm for 8h; then raise the shelf t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com