System and method for synthesizing rubber scorch retarder CTP through continuous flow micro-reaction

一种合成橡胶、防焦剂的技术,应用在化学仪器和方法、化学/物理/物理化学反应器、化学/物理/物理化学过程等方向,能够解决副反应多、反应时间长、传质效率差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

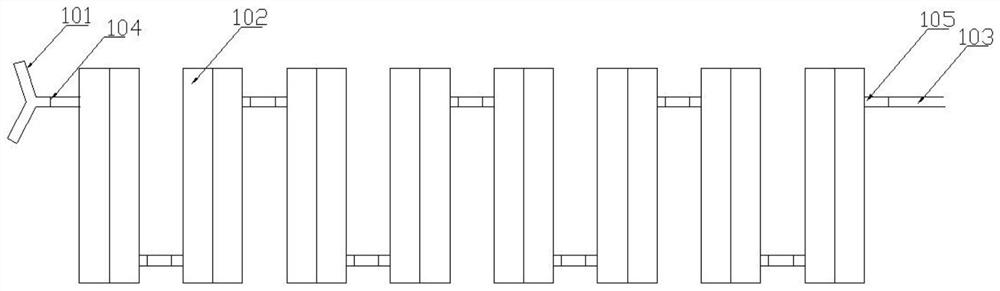

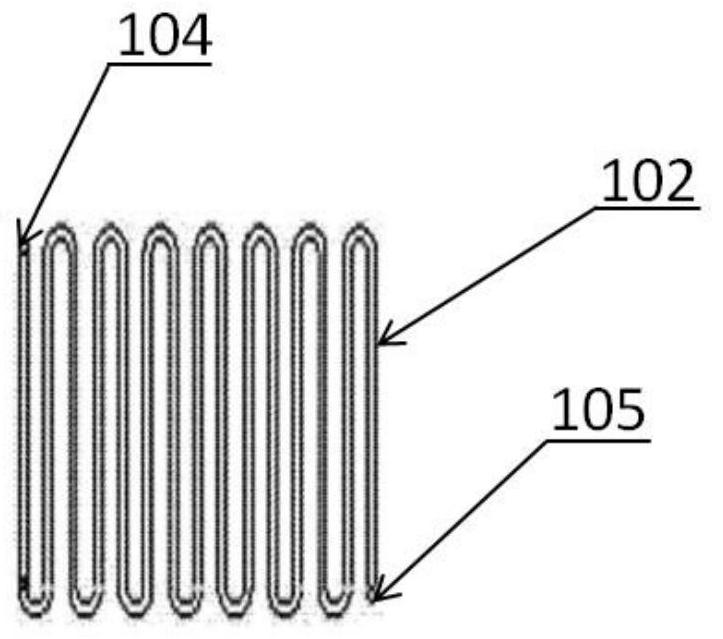

[0063] Continuous flow micro-reaction synthetic rubber anti-scorch agent CTP system

[0064] This embodiment provides a Figure 5 The shown continuous flow micro-reaction synthetic rubber anti-scorch agent CTP system includes: cyclohexyl sulfenyl chloride and catalyst mixed solution delivery pipeline 1, phthalimide sodium salt and catalyst mixed solution delivery pipeline 2, micro-reaction device 11, acidity Meter 12 and post-processing device 13.

[0065] In this embodiment, the cyclohexylsulfenyl chloride and catalyst mixed liquid delivery pipeline 1 is sequentially provided with a first filter 3, a first advection metering pump 5, a first mass flow meter 7 and a first pressure gauge9.

[0066] In this embodiment, the phthalimide sodium salt and the catalyst mixed liquid delivery pipeline 2 are sequentially provided with a second filter 4, a second advection metering pump 6, a second mass flow meter 8 and a second flow meter along the mixed liquid delivery direction. Two ...

Embodiment 2

[0075] Method for synthesizing rubber anti-scorch agent CTP by continuous flow micro-reaction

[0076] Carry out the synthesis of rubber anti-scorch agent CTP in the system that embodiment 1 provides, wherein, the micro-reaction device in the described system selects Y-type feed inlet microchannel reactor, and concrete synthetic process is as follows:

[0077]Mix the catalyst (benzyltriethylammonium chloride) evenly into the prepared cyclohexylsulfenyl chloride solution with a concentration of 12 to 25 wt% and a temperature of -5 to 15°C. The amount of the catalyst is cyclohexyl 5‰ of the mass of the sulfenyl chloride solution; the prepared sodium phthalimide solution with a concentration of 15-30 wt% is stored in an environment of -3-10°C.

[0078] Start the first and second advection metering pumps simultaneously afterwards, and the mixed solution of cyclohexylsulfenyl chloride and catalyst (referred to as reaction solution A) and phthalimide sodium salt solution (referred t...

Embodiment 3

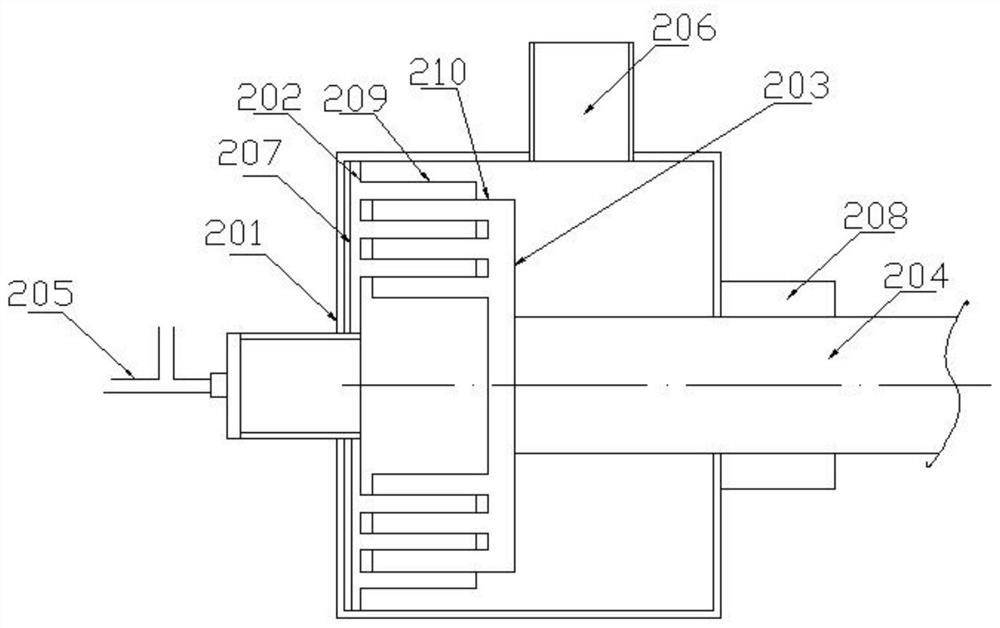

[0082] Method for synthesizing rubber anti-scorch agent CTP by continuous flow micro-reaction

[0083] Carry out the synthesis of rubber anti-scorch agent CTP in the system that embodiment 1 provides, wherein, the micro-reaction device in the described system selects to have multi-stage stator-rotor high-shear reactor, and concrete synthetic process is as follows:

[0084] Mix the catalyst (benzyltriethylammonium chloride) evenly into the sodium phthalimide salt solution with a concentration of 15-30wt% and a temperature of -3-10°C. The amount of catalyst used is sodium phthalimide 5‰ of the quality of the salt solution; the prepared cyclohexylsulfenyl chloride solution with a concentration of 12-25 wt% is stored in an environment of -5-15°C.

[0085] Start the first and second advection metering pumps simultaneously afterwards, and the mixed solution of cyclohexylsulfenyl chloride solution (referred to as reaction solution A) and phthalimide sodium salt and catalyst (referred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com