High-efficiency low-temperature honeycomb type SCR denitration catalyst and preparation method thereof

A denitrification catalyst and honeycomb-type technology, applied in the field of denitrification catalysts, can solve the problem of catalyst NOx removal activity reduction, etc., and achieve the effects of easy large-scale industrial production, high removal rate, and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

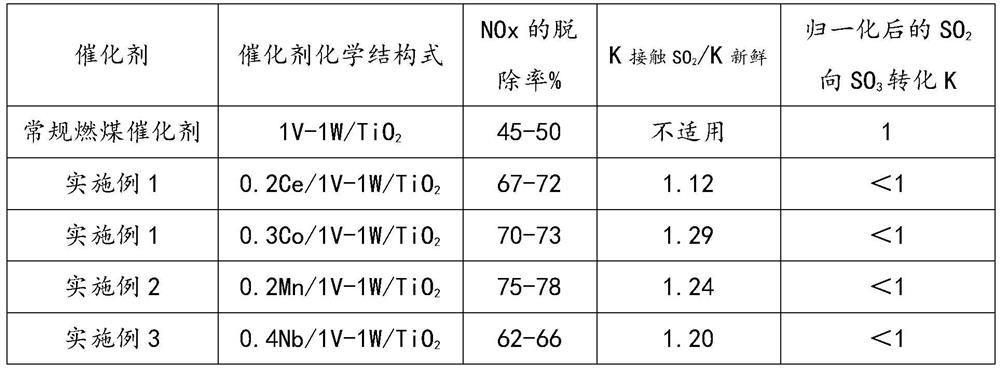

Examples

preparation example Construction

[0022] It can be understood that the present invention uses some embodiments in order to achieve the purpose of the present invention. The present invention provides a method for preparing a high-efficiency low-temperature honeycomb SCR denitration catalyst, comprising the following steps:

[0023] S1 In a temperature environment of 60-80°C, add carriers, active agents, active substances, compound additives, active agents, binders, lubricants, pore-forming agents and solvents and stir and mix in the reactor for 6-12 hours , the mixed mud material is obtained and extruded into a honeycomb mud billet;

[0024] The S2 honeycomb mud is dried at a temperature of 80-130°C for 8-24 hours to obtain a dried honeycomb mud;

[0025] S3 The dried honeycomb mud is roasted at a temperature of 550-600°C for 12-36 hours to obtain a high-efficiency low-temperature honeycomb SCR denitration catalyst;

[0026] Wherein the carrier is TiO in the step S1 2 , the coagent is WO 3 , the active subs...

Embodiment 1

[0032] This embodiment provides a method for preparing a high-efficiency low-temperature honeycomb SCR denitration catalyst, including the following steps:

[0033] S1 weighs the precursor material of the catalyst and weighs the carrier TiO 2 Powder 2000g, according to the carrier TiO in high-efficiency low-temperature honeycomb SCR denitration catalyst 1 2 , coagent WO 3 , active substance V 2 o 5 The weight ratio of 8:1:1 is reversed to calculate the carrier TiO in the precursor material of the corresponding catalyst 2 , coagent WO 3 and active substance V 2 o 5 weight, and on the carrier TiO 2 , coagent WO 3 and active substance V 2 o 5 Carry out calculation and weighing, and add cerium nitrate according to the molar ratio of V element and Ce element in the high-efficiency low-temperature honeycomb SCR denitration catalyst at a ratio of 1:0.2, calculate and weigh the appropriate proportion of binder, stearic acid, kapok and ammonia water ;

[0034] S2 Prepare th...

Embodiment 2

[0038] This embodiment provides a method for preparing a high-efficiency low-temperature honeycomb SCR denitration catalyst, including the following steps:

[0039] S1 weighs the precursor material of the catalyst and weighs the carrier TiO 2 Powder 2600g, according to the high-efficiency low-temperature honeycomb SCR denitration catalyst 2 carrier TiO 2 , coagent WO 3 , active substance V 2 o 5 The weight ratio of 8:1:1 is reversed to calculate the carrier TiO in the precursor material of the corresponding catalyst 2 , coagent WO 3 and active substance V 2 o 5 weight, and on the carrier TiO 2 , coagent WO 3 and active substance V 2 o 5 Carry out calculation and weighing, and add cobalt nitrate according to the molar ratio of V element and Co element in the high-efficiency low-temperature honeycomb SCR denitration catalyst at a ratio of 1:0.3, and calculate and weigh the binder, Stearic acid, kapok and ammonia;

[0040]S2 Prepare the mixed mud by weighing the precu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com