Hf-containing multi-element boron-free nickel-based alloy brazing filler metal, and preparation method and brazing method of Hf-containing multi-element boron-free nickel-based alloy brazing filler metal

A technology of nickel-based alloy and brazing method, applied in metal processing equipment, welding medium, manufacturing tools, etc., can solve problems such as residual stress thermal damage, chemical erosion, diamond graphitization, etc., to improve wear resistance and lower melting point , to suppress the effect of generating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

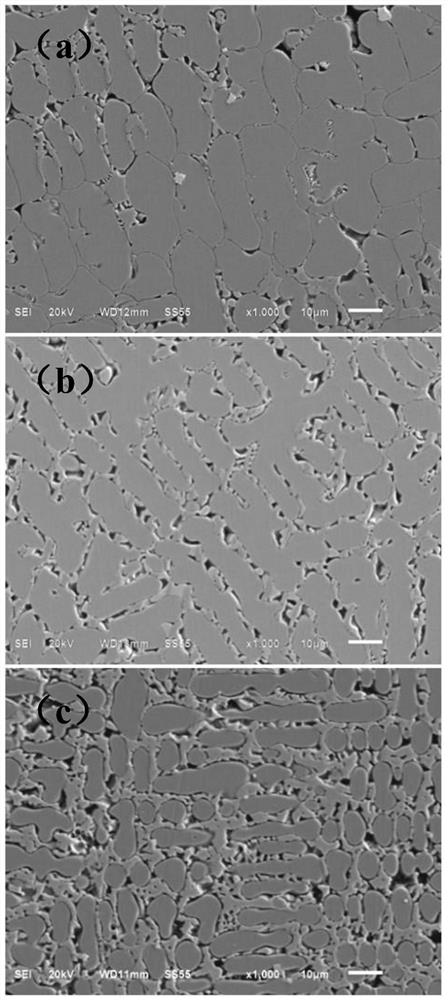

[0040] Composition (mass percentage): Ni: 55.0%, Cr: 15.0%, Si: 5.0%, Cu: 20.0%, Sn: 5.0%, Hf: 0%.

[0041] Preparation:

[0042] (1) Weigh the corresponding elemental metal raw materials according to the mass percentage of each element: use sandpaper to polish the oxide skin and impurities on the surface of the corresponding elemental metal raw materials, and weigh the corresponding 5.5g Ni, 1.5g Cr, 0.5g Si, 2g Cu, 0.5g Sn , and ultrasonically cleaned with acetone for about 10 minutes, dried for later use.

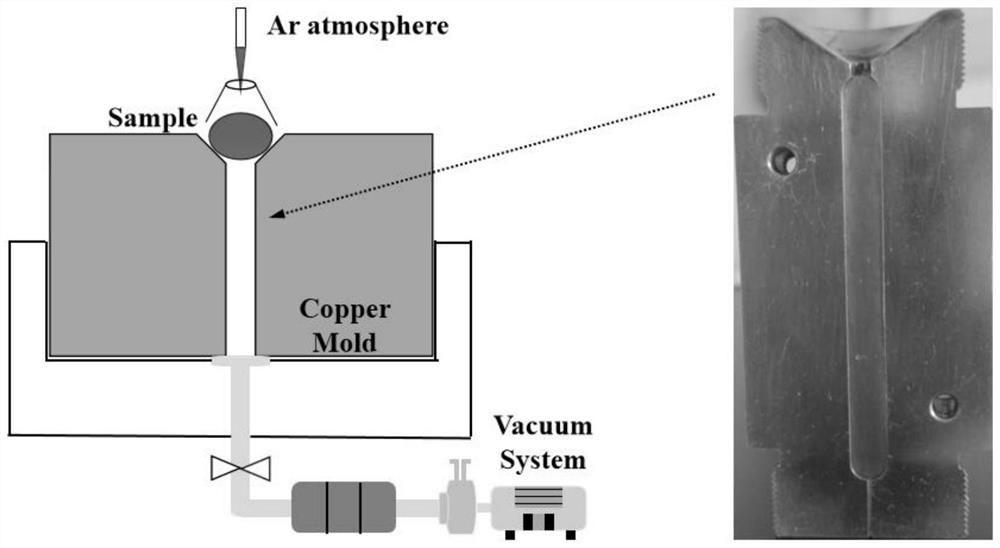

[0043] (2) Place the dried metal raw material in a vacuum electric arc furnace, and evacuate to a vacuum degree of 3×10 -3 Pa, and Ar gas is passed in as a protective gas, and the raw materials of various metals are put into the crucible from top to bottom according to the melting point, and the Sn metal is at the bottom, which can effectively avoid the volatilization of raw materials during smelting; The material alloy is remelted-solidified-remelted-solidified 3 to 4...

Embodiment 2

[0049] Composition (mass percentage): Ni: 54.0%, Cr: 15.0%, Si: 5.0%, Cu: 20.0%, Sn: 5.0%, Hf: 1.0%.

[0050] (1) Weigh the corresponding elemental metal raw materials according to the mass percentage of each element: sand the scale and impurities on the surface of the corresponding elemental metal raw materials and weigh the corresponding 5.4g Ni, 1.5g Cr, 0.5g Si, 2g Cu, 0.5g Sn and 0.1gHf, and ultrasonically cleaned with acetone for about 10 minutes, dried for use.

[0051] (2) Place the dried metal raw material in a vacuum electric arc furnace, and evacuate to a vacuum degree of 3×10 -3 Pa, and Ar gas is introduced as a protective gas, and the raw materials of various metals are put into the crucible from top to bottom according to the melting point, and the Sn metal is at the bottom, which can effectively avoid the volatilization of raw materials during smelting; The material alloy is remelted-solidified-remelted-solidified 3 to 4 times, and after the solder alloy is coo...

Embodiment 3

[0057] Composition (mass percentage): Ni: 51.0%, Cr: 15.0%, Si: 5.0%, Cu: 20.0%, Sn: 5.0%, Hf: 4.0%

[0058] (1) Weigh the corresponding elemental metal raw materials according to the mass percentage of each element: use sandpaper to polish the oxide skin and impurities on the surface of the corresponding elemental metal raw materials, and weigh the corresponding 5.1g Ni, 1.5g Cr, 0.5g Si, 2g Cu, 0.5g Sn and 0.4gHf, and ultrasonically cleaned with acetone for about 10 minutes, dried for later use.

[0059] (2) Place the dried metal raw material in a vacuum electric arc furnace, and evacuate to a vacuum degree of 3×10 -3 Pa, and Ar gas is introduced as a protective gas, and the raw materials of various metals are put into the crucible from top to bottom according to the melting point, and the Sn metal is at the bottom, which can effectively avoid the volatilization of raw materials during smelting; The material alloy is remelted-solidified-remelted-solidified 3 to 4 times, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com