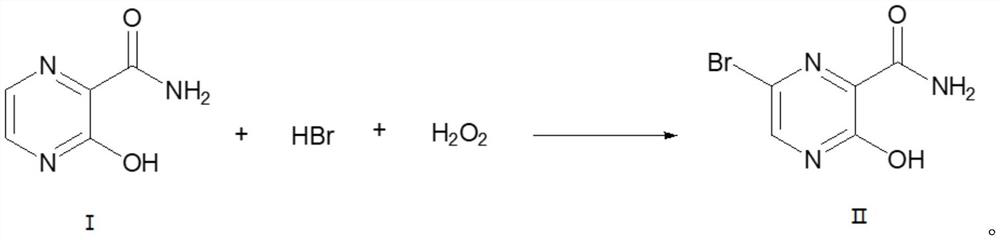

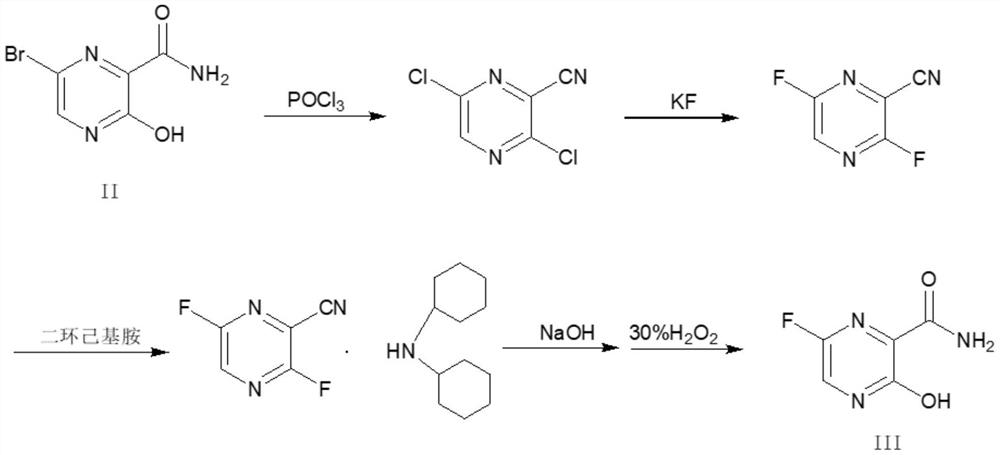

Synthetic method of favipiravir intermediate 6-bromo-3-hydroxypyrazine-2-formamide

A technology of hydroxypyrazine and favipiravir, which is applied in the synthesis of pharmaceutical intermediates and the synthesis of 6-bromo-3-hydroxypyrazine-2-carboxamide, which can solve sudden temperature rise, high reaction temperature, and increased storage costs and other problems, to achieve the effect of increasing post-treatment pressure, high purity and content, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 200mL 1,2-dichloroethane and 100g 3-hydroxypyrazine-2-carboxamide (I) (0.72mol) and 174.96g 40% hydrobromic acid aqueous solution (0.864mol) in the four-necked flask, control temperature 0°C to 20°C, stir, slowly add 163.2g (1.44mol) of 30% hydrogen peroxide dropwise, keep warm for 5 minutes after the dropwise addition, stop the reaction, cool the system, separate the water layer, wash the organic layer twice with 200mL purified water, The solvent was evaporated to dryness and dried in a vacuum oven at 40°C to obtain 145.54 g of 6-bromo-3-hydroxypyrazine-2-carboxamide (II), with a yield of 92.8%, an HPLC purity of 99.92%, and an external standard content of 99.5%.

Embodiment 2

[0035] Add 800mL 1,2-dichloroethane and 100g 3-hydroxypyrazine-2-carboxamide (I) (0.72mol) and 194.4g 48% hydrobromic acid aqueous solution (1.152mol) in the four-neck flask, control temperature -10°C~0°C, stir, slowly add 391.7g (5.76mol) of 50% hydrogen peroxide dropwise, keep it warm for 2 hours after the dropwise addition, stop the reaction, cool the system, separate the water layer, and wash the organic layer twice with 800mL purified water , evaporated the solvent to dryness, and put it into a vacuum oven for drying at 70° C. to obtain 147.11 g of 6-bromo-3-hydroxypyrazine-2-carboxamide (II), with a yield of 93.8%, an HPLC purity of 99.93%, and an external standard content of 99.3%.

Embodiment 3

[0037] Add 200mL 1,2-dichloroethane and 100g 3-hydroxypyrazine-2-carboxamide (I) (0.72mol) and 145.8g 48% hydrobromic acid aqueous solution (0.864mol) in the four-necked flask, control temperature Stir at 20°C to 30°C, slowly add 391.7g (5.76mol) of 50% hydrogen peroxide dropwise, keep the temperature for 60 minutes after the dropwise addition, stop the reaction, cool the system, separate the water layer, wash the organic layer twice with 200mL purified water, Evaporate the solvent to dryness and dry in a vacuum oven at 50°C to obtain 144.76gg of 6-bromo-3-hydroxypyrazine-2-carboxamide (II), with a yield of 92.3%, an HPLC purity of 99.91%, and an external standard content of 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com