Polytrifluorochloroethylene film as well as preparation method and application thereof

A polychlorotrifluoroethylene and film technology, which is applied in the field of polychlorotrifluoroethylene film preparation, can solve the problems of unobtainable performance and excellent film products, and achieve the effect of maintaining performance advantages and avoiding degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

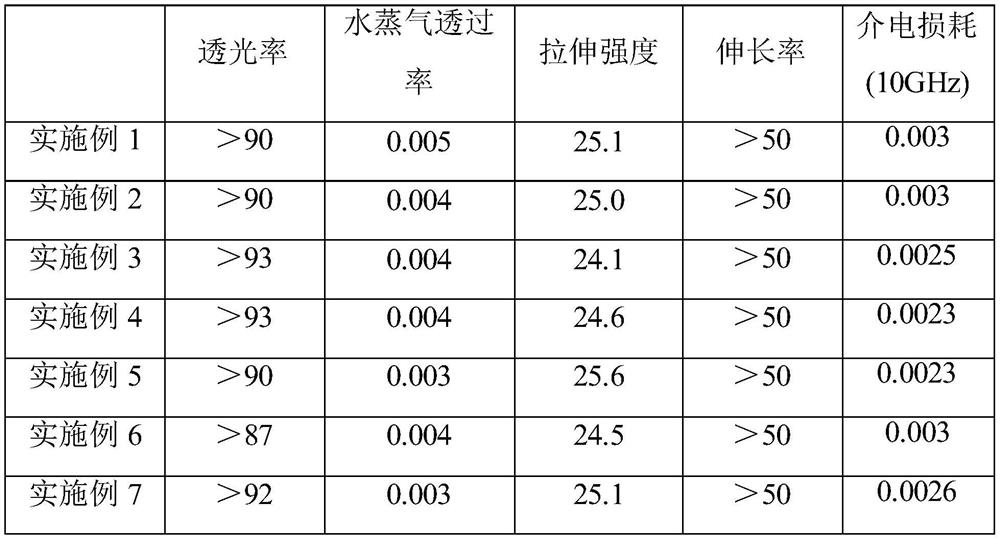

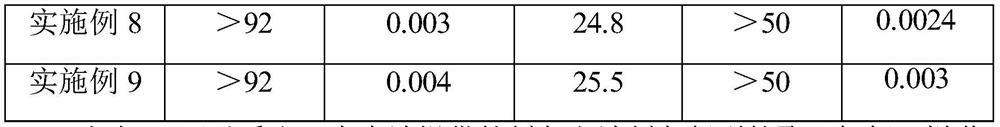

Examples

preparation example Construction

[0044] In view of this, the present application creatively proposes a method for preparing a polychlorotrifluoroethylene film, which mainly includes the following steps: the polychlorotrifluoroethylene suspension obtained after dispersing polychlorotrifluoroethylene in a mixed dispersion medium is supported on The surface of the substrate material is dried, sintered, and the substrate material is subsequently removed.

[0045] The method is to prepare the PCTFE film by carrying the suspension on the substrate material, followed by drying, sintering and removing the substrate material. This method does not have too high requirements on the fluidity of the polymer melt, and PCTFE can be formed without additional high-pressure and high-shear effects, that is, the entire process is carried out without high temperature (the maximum forming temperature is not higher than 280°C). And high force field (including extrusion or shear force) environment, effectively avoiding the degradati...

Embodiment 1

[0080] The present embodiment provides a kind of preparation method of polychlorotrifluoroethylene film, specifically as follows:

[0081] First, weigh 2g of sodium dodecylbenzenesulfonate and dissolve it in 80g of deionized water, then add it together with 80g of PCTFE powder into the mixing tank, set the speed of the mixer to 400rpm, and the mixing time to 24h, then use ammonia water to adjust the pH of the system When the value reaches 10.0, a stable PCTFE suspension is obtained. Next, using high borosilicate glass as the substrate material, an automatic coating machine is used to coat a wet film of PCTFE suspension with a thickness of 40 μm on the high borosilicate glass. Then, set the temperature of the coater to 60°C, and dry the wet film thoroughly. Next, move the glass and the dry film it carries into the sintering furnace and place it horizontally, set the heating rate at 20°C / min, sinter at 210°C for 15 minutes, and then sinter at 260°C for 35 minutes. Finally, put...

Embodiment 2

[0083] Weigh 1.5g of sodium perfluorobutane sulfonate and 0.5g of sodium cetyl sulfate and dissolve them in 80g of deionized water. The rest of the operating steps and equipment are the same as in Example 1. Finally, a colorless and transparent PCTFE film is obtained with a thickness of about 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com