Non-noble metal chlorine evolution catalyst electrode and preparation method thereof

A non-precious metal and catalyst technology, applied in the field of non-precious metal chlorine analysis catalyst electrode and preparation, to achieve the effect of improving electrocatalytic activity, harmless to the environment, and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

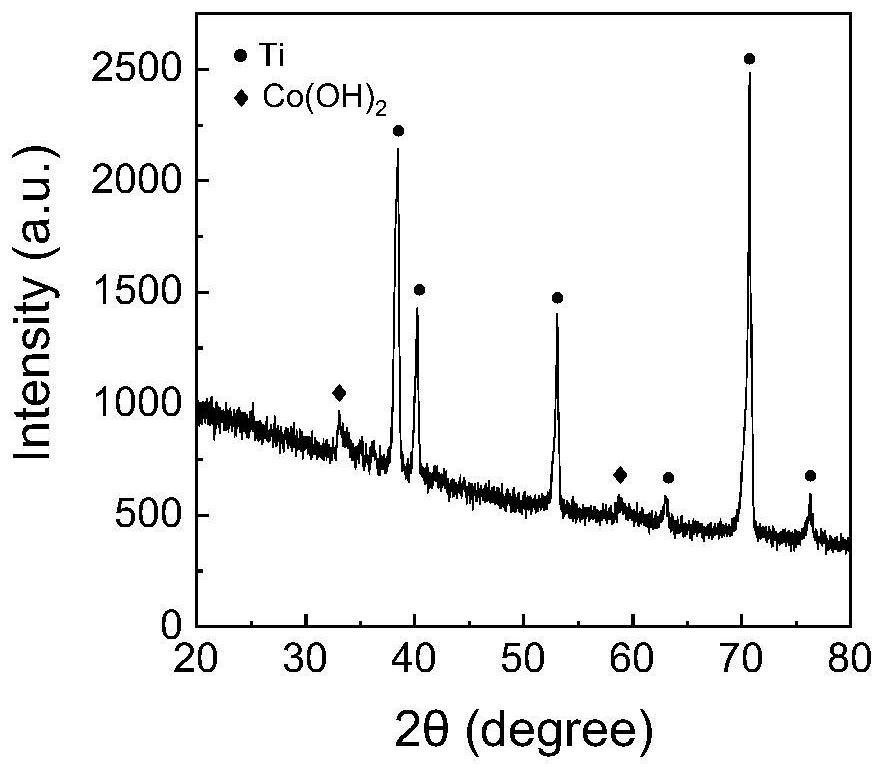

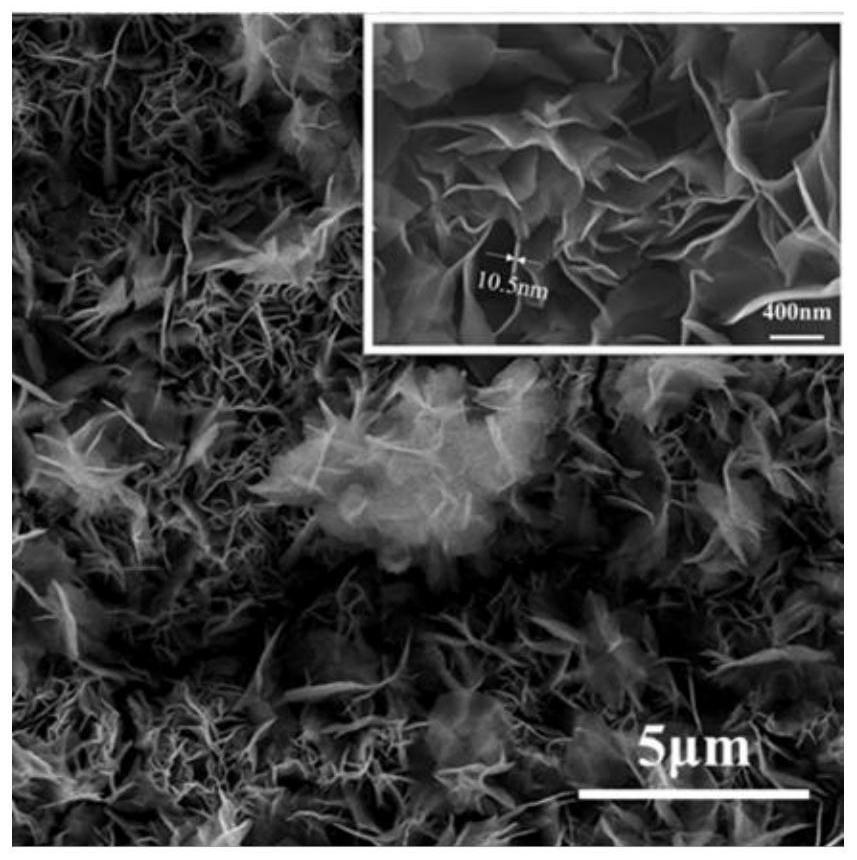

[0022] Example 1 The non-precious metal chlorine evolution catalyst electrode provided in this example mainly consists of a titanium mesh and a thin film catalyst Co(OH) on the surface of the titanium mesh. 2 constitute.

[0023] The non-noble metal chlorine analysis catalyst electrode of this embodiment is prepared by a cathode constant voltage electrodeposition method, which specifically includes the following steps:

[0024] (1) Cut the titanium mesh with a purity of 99.99% by 1cm×1cm, and rinse the surface of the titanium mesh with distilled water. After rinsing, use absolute ethanol to ultrasonically clean it for 20 minutes. After cleaning, pour out the absolute ethanol and replace it with distilled water for 20 minutes of ultrasonic cleaning. After cleaning, put it in an oven at 60 °C to make the surface dry quickly .

[0025] (2) Clamp the treated titanium mesh with the electrode holder as the working electrode, and the platinum mesh and saturated calomel electrode as...

Embodiment 2

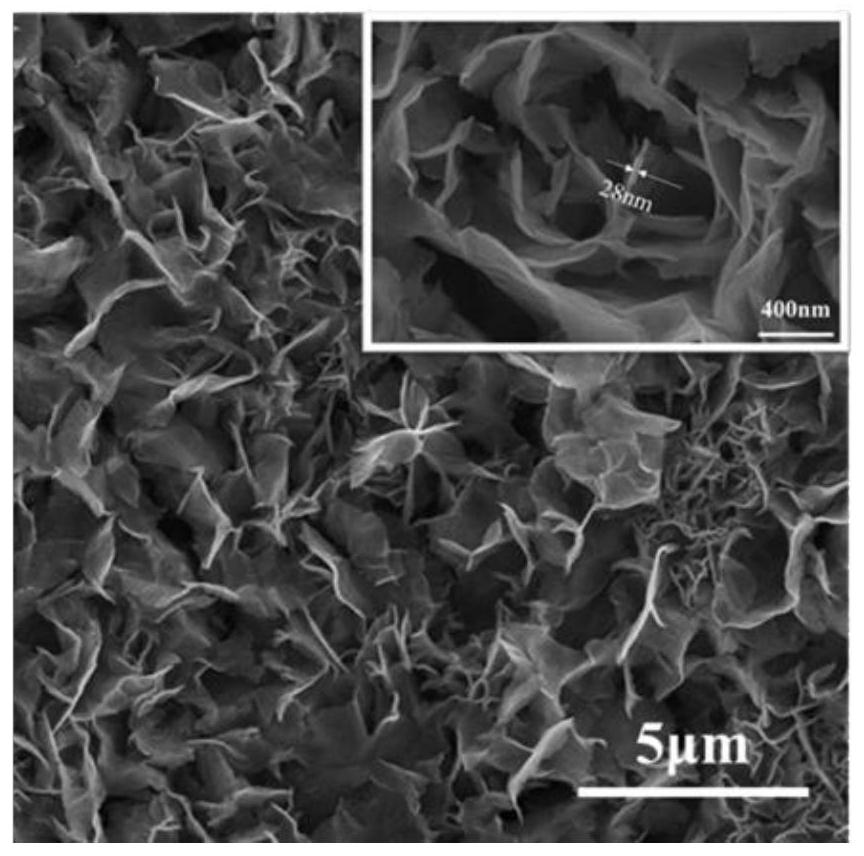

[0033] Example 2 The non-precious metal chlorine evolution catalyst electrode provided in this example mainly consists of a titanium sheet and a thin film catalyst Co(OH) on the surface of the titanium sheet. 2 constitute.

[0034] The non-noble metal chlorine evolution catalyst electrode of this embodiment is prepared by a cathode constant voltage electrodeposition method, which specifically includes the following steps:

[0035] (1) Cut the titanium sheet by 1cm×1cm, and rinse the surface of the titanium sheet with distilled water. After rinsing, use absolute ethanol to ultrasonically clean it for 20 minutes. After cleaning, pour out the absolute ethanol and replace it with distilled water for 20 minutes of ultrasonic cleaning. After cleaning, put it in an oven at 60 °C to make the surface dry quickly .

[0036] (2) Clamp the processed titanium sheet with an electrode holder as the working electrode, and the platinum mesh and saturated calomel electrode as the counter elec...

Embodiment 3

[0038] Example 3 The non-noble metal chlorine evolution catalyst electrode provided in this example is mainly composed of a titanium sheet and a catalyst Co(OH) on the surface of the titanium sheet. 2 constitute.

[0039] The non-noble metal chlorine analysis catalyst electrode of this embodiment is prepared by a cathode constant voltage electrodeposition method, which specifically includes the following steps:

[0040] (1) Cut the titanium sheet by 1cm×1cm, and rinse the surface of the titanium sheet with distilled water. After rinsing, use absolute ethanol to ultrasonically clean it for 20 minutes. After cleaning, pour out the absolute ethanol and replace it with distilled water for 20 minutes of ultrasonic cleaning. After cleaning, put it in an oven at 60 °C to make the surface dry quickly .

[0041] (2) Clamp the processed titanium sheet with an electrode holder as the working electrode, and the platinum mesh and saturated calomel electrode as the counter electrode and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com