Preparation method of nitrogen-rich ionic liquid polymer and application of nitrogen-rich ionic liquid polymer in catalytic hydrogenation reaction

A technology of ionic liquids and polymers, applied in the field of palladium catalysts, can solve problems such as unsatisfactory designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of nitrogen-enriched ionic liquid polymer:

[0032] (1) By reacting imidazole and cyanuric chloride, the precursor trimidazole-triazine TIMT of synthesizing triimidazole triazine structure: imidazole (6g, 80mmol) and cyanuric chloride (3g, 16mmol) are dissolved in 40ml THF, in Mix in a three-necked flask, stir for 24 hours at 80°C under a nitrogen atmosphere, filter and wash with water, and dry to obtain 3.3 g of white precipitate, with a yield of 78.6%;

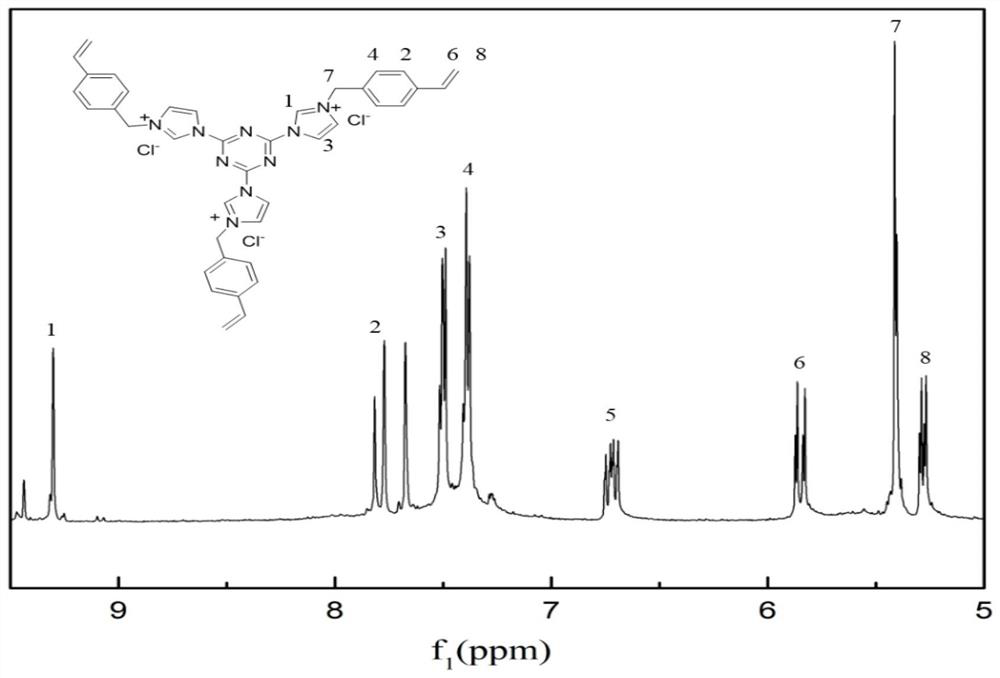

[0033] (2) Synthesis of ionic liquid with 4-vinylbenzyl chloride and trimidazole-triazine (TIMT): step (1) product TIMT (0.6g, 2.15mmol) and vinylbenzyl chloride (1.2g, 7.9mmol), DMSO 15ml As a solvent, stir for 48 hours under a nitrogen atmosphere at 80°C to obtain a dark brown liquid. After the reaction, wash with ethyl acetate three times to remove unreacted vinylbenzyl chloride and solvent DMSO, and dry the solid by centrifugation to obtain light yellow powder Cl-IL 1.4g, yield 88.6%;

[0034] (3) Cl...

Embodiment 2

[0037] Metal load: the PIL-Tf that the vacuum drying that embodiment obtains obtains 2 N 1g and enough chloropalladic acid were stirred in water at room temperature for 24 hours. Filtered, dried in vacuo, and the solid was reduced with excess sodium borohydride solution to give 2wt% Pd-PIL-TF 2 N.

[0038] Same as above, using PIL-Cl-IL, PIL-PF 6 -IL carries out metal loading, and ICP-MS test shows that the actual loading is 1.05wt% Pd-PIL-Tf 2 N, 1.05wt% Pd-PIL-Cl, 1.55wt% Pd-PIL-PF 6 catalyst.

Embodiment 3

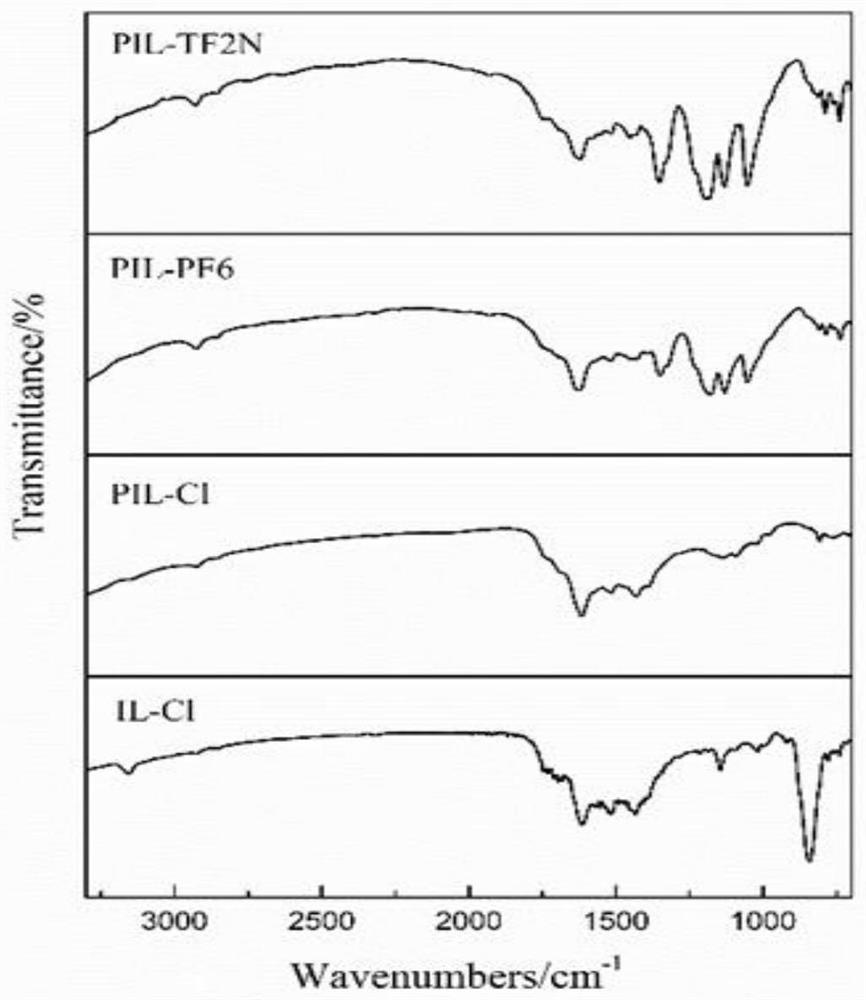

[0040] In order to confirm the successful polymerization of polyionic liquids and determine the structure of the polymerized catalyst, the synthesized polyionic liquids were characterized by FT-IR. Three kinds of polyionic liquids after anion exchange (PIL-Tf 2 N, PIL-Cl, PIL-PF 6 ) infrared spectrum such as figure 2 shown.

[0041] Such as figure 2 As shown, the three catalysts are all at 2960-2840cm -1 There are obvious absorption peaks between the three catalysts and the monomers contain -CH 2 -structure. Compared with other catalysts, the monomer IL-Cl catalyst is at 3150cm -1 There is a relatively obvious absorption peak, here is the vinyl C-H stretching vibration peak, 840cm -1 There is an obvious peak at , which is the out-of-plane rocking vibration absorption peak of vinyl. None of the two peaks existed in the three polymerized catalysts, which proved that the free radical polymerization with AIBN as the initiator was successful. All three catalysts are at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com