Microporous rubber backing plate and production method thereof

A technology of microporous rubber and backing plate, which is applied to other household appliances, flat products, household appliances, etc., can solve the problems of products with excellent performance parameters, complicated processes, and increased production line costs, so as to shorten the production cycle and reduce the microporous The effect of uniform distribution and simplified production process

Active Publication Date: 2022-05-31

HEBEI TIEKE YICHEN NEW MATERIAL TECH CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the production of this kind of products is mainly produced by the two-stage vulcanization method, first vulcanized in the mold, then cooled, and then further baked and solidified in the oven, the process is complicated

Aiming at the above defects, CN110484917A discloses a microporous rubber backing plate and its preparation method, which is made of the following raw materials in proportion by weight: 100 parts of EPDM, 4-10 parts of active agent, 2-4 parts of anti-aging agent, 50-150 parts of reinforcing filler, 30-70 parts of softening plasticizer, and 5-10 parts of vulcanizing agent, after one stage of mixing, two stages of mixing, extrusion, cutting, and vulcanization, the product is obtained. The technical solution Although the production process has been simplified to a certain extent, it has not obtained products with excellent performance parameters.

CN109096619A discloses a new type of elastic support block type slag-free track foam pad, including the following process steps: mixing, extrusion molding, embossing, high temperature setting, microwave vulcanization, hot air vulcanization, forced cooling, automatic cutting, The introduction of microwave vulcanization increases the cost of the production line

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

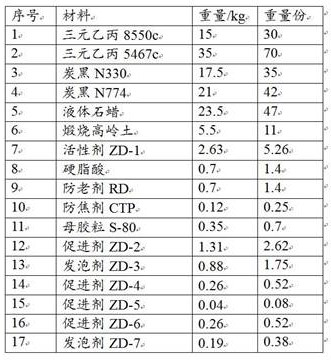

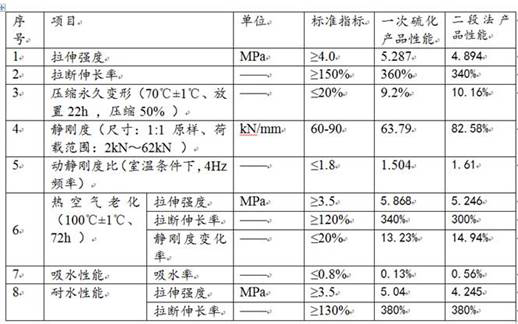

Embodiment 1

[0035]

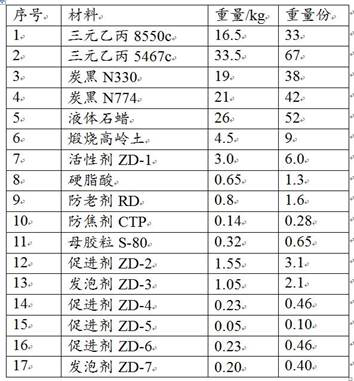

Embodiment 2

[0051]

Embodiment 3

[0067]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a microporous rubber backing plate and a preparation method thereof, which is made of the following raw materials in parts by weight: 100 parts of EPDM rubber, 70-85 parts of carbon black, 42-52 parts of liquid paraffin, and calcined kaolin 9~13 parts, 1.3~1.5 parts of stearic acid, 1.2~1.6 parts of antioxidant RD, 0.22~0.28 parts of anti-scorch agent CTP, 0.65~0.75 parts of masterbatch S‑80, 4.5~6.0 parts of active agent ZD‑1 , accelerator ZD‑2 2.1~3.1 parts, blowing agent ZD‑3 1.4~2.1 parts, accelerator ZD‑4 0.45~0.60 parts, accelerator ZD‑5 0.06~0.11 parts, accelerator ZD‑6 0.45~0.60 parts, blowing agent ZD-7 0.33~0.41 parts. The micropore distribution of the rubber backing plate obtained by the present invention is even, strong in elasticity, has lower static stiffness and dynamic-static stiffness ratio, and still has excellent tensile strength and elongation at break under heat-resistant and water-resistant conditions, and is especially suitable for Passenger and freight collinear and heavy-haul railway ballastless track shock absorption.

Description

Microporous rubber backing plate and production method thereof technical field The present invention relates to the technical field of microporous rubber backing plate, in particular to a kind of microporous rubber backing plate and production method thereof. Background technique [0002] The microporous rubber backing plate is used in the ballastless track, and is wrapped in the boots together with the concrete blocks on it. The bottom of the support block acts as a shock absorber to reduce the vibration and shock generated when the train is running, and reduce the compressive stress of the track bed and roadbed. Reduce the deformation and damage of the track bed and protect the track bed. At present, mainly adopt two-stage vulcanization production for the production of this type of product, first vulcanize in mould, then cold However, it is further baked and cured in the oven, and the process is complicated. In view of the above defects, CN110484917A discloses a mic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08J9/10C08J9/00C08L23/16C08L91/06C08K3/04C08K3/34C08K5/09C08K13/02B29C48/505B29C48/625B29D7/01

CPCC08J9/103C08J9/0061C08J9/0095B29D7/01B29C48/505B29C48/625C08J2203/04C08J2323/16C08J2423/16C08J2491/06C08K3/04C08K3/346C08K5/09C08K13/02C08J2205/044

Inventor 崔永生杨凯仇鹏闫思梦吴明明胡学欢姜若琳陈敬牛伟

Owner HEBEI TIEKE YICHEN NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com