Graphdiyne modified polyimide ultrasonic motor friction material and preparation method thereof

A polyimide, ultrasonic motor technology, applied in the field of polymer composite materials, can solve the problems of high surface free energy, short service life, poor creep resistance, etc., to improve mechanical strength, improve wear resistance, mechanical The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The parts by mass of the components of the graphyne-modified polyimide composite material for ultrasonic motors are as follows: 100 g of polyimide, 1 g of graphyne, 1 g of carbon nanotubes, and 1 g of aluminum oxide.

[0028] Concrete preparation steps:

[0029] 1) adding polyimide, graphyne, carbon nanotubes, and alumina powder into alcohol for ball milling for 4 hours, mixing thoroughly, and then drying, pulverizing, and sieving;

[0030] 2) Pour the mixed molding material into the mold for hot pressing and sintering molding. The molding temperature is 375°C, the pressure is 20MPa, and the mold is demoulded by natural cooling;

[0031] 3) Slicing the polyimide composite material, pasting it with the aluminum alloy rotor and surface treatment for the ultrasonic motor.

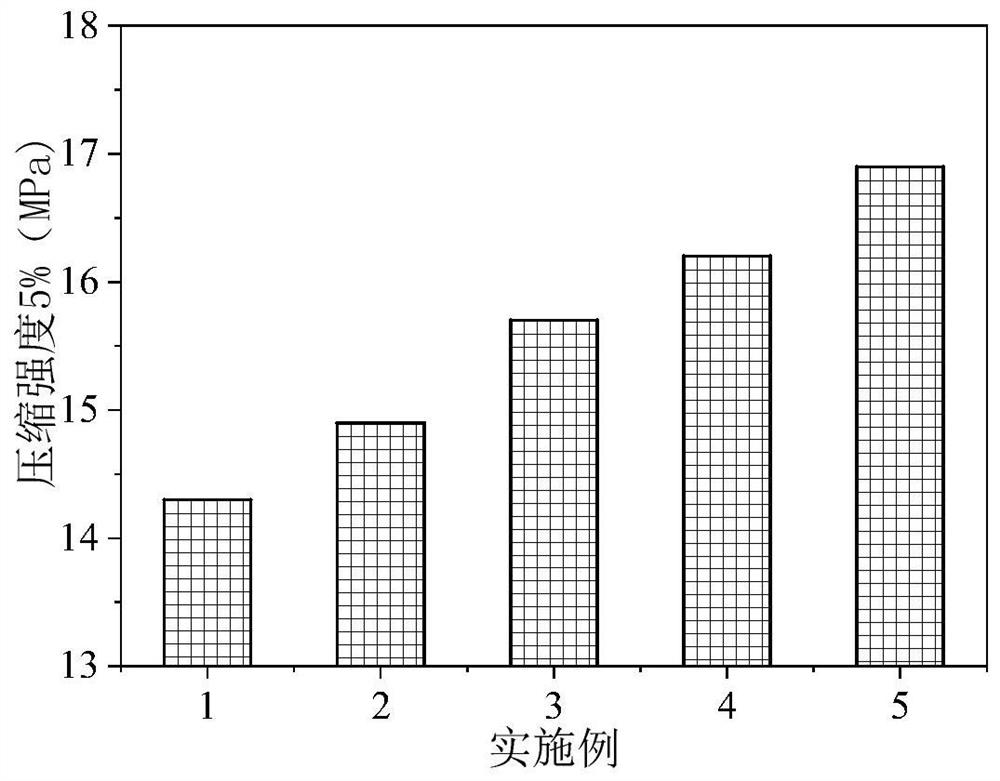

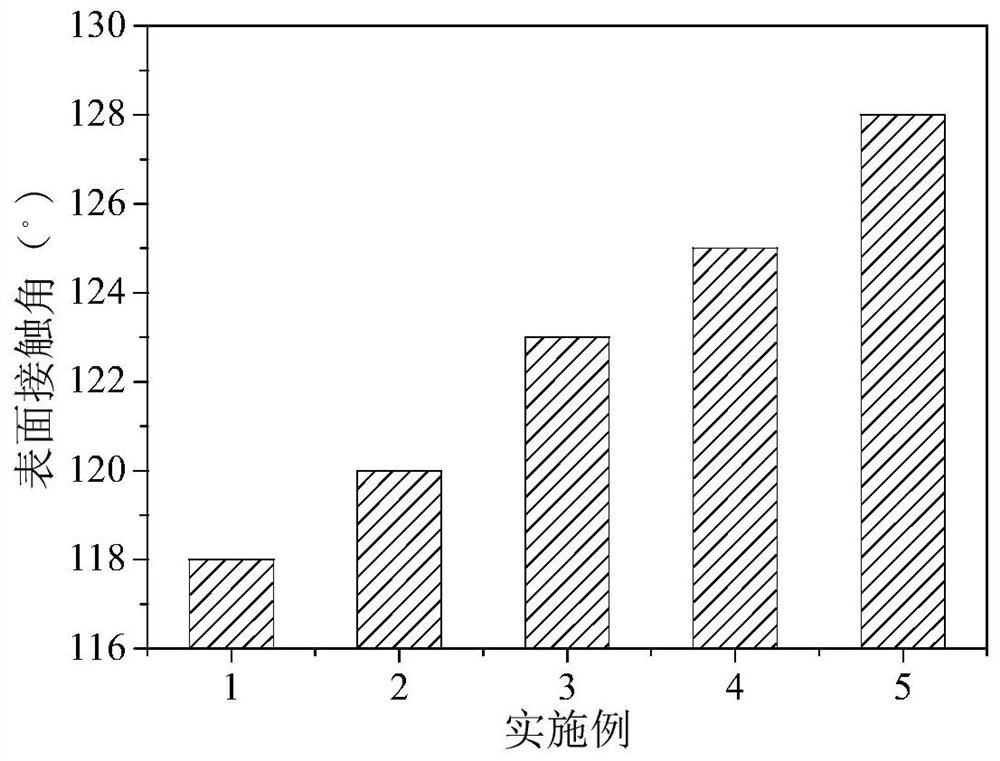

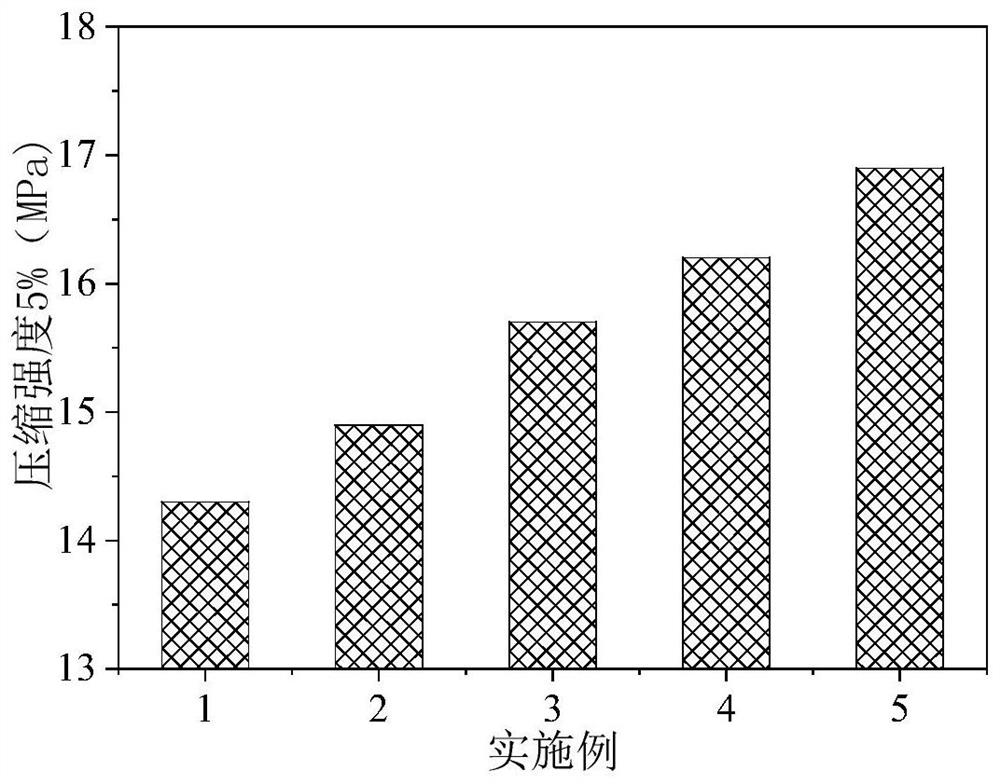

[0032] The compressive strength 5% of the polyimide composite material prepared in this example is 14.3MPa, the contact angle is 118°, the friction coefficient with the phosphor bronze stator pair is 0...

Embodiment 2

[0034] The parts by mass of the components of the graphyne-modified polyimide composite material for ultrasonic motors are as follows: 100 g of polyimide, 2 g of graphyne, 2 g of carbon nanotubes, and 2 g of aluminum oxide.

[0035] Concrete preparation steps:

[0036] 1) adding polyimide, graphyne, carbon nanotubes, and alumina powder into alcohol for ball milling for 5 hours, fully mixing, and then drying, pulverizing and sieving;

[0037] 2) Pour the mixed molding material into the mold for hot pressing and sintering molding. The molding temperature is 375°C, the pressure is 20MPa, and the mold is demoulded by natural cooling;

[0038] 3) Slicing the polyimide composite material, pasting it with the aluminum alloy rotor and surface treatment for the ultrasonic motor.

[0039] The compressive strength 5% of the polyimide composite material prepared in this example is 14.9MPa, the contact angle is 120°, the friction coefficient with the phosphor bronze stator pair is 0.169 u...

Embodiment 3

[0041] The parts by mass of the components of the graphyne-modified polyimide composite material for ultrasonic motors are as follows: 100 g of polyimide, 3 g of graphyne, 3 g of carbon nanotubes, and 3 g of aluminum oxide.

[0042] Concrete preparation steps:

[0043] 1) adding polyimide, graphyne, carbon nanotubes, and alumina powder into alcohol for ball milling for 6 hours, fully mixing, and then drying, pulverizing, and sieving;

[0044] 2) Pour the mixed molding material into the mold for hot pressing and sintering molding. The molding temperature is 375°C, the pressure is 20MPa, and the mold is demoulded by natural cooling;

[0045] 3) Slicing the polyimide composite material, pasting it with the aluminum alloy rotor and surface treatment for the ultrasonic motor.

[0046] The compressive strength 5% of the polyimide composite material prepared in this example is 15.7MPa, the contact angle is 123°, the friction coefficient with the phosphor bronze stator pair is 0.164 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com