Controllable magnetic force release microcapsule, preparation method, release control method and application thereof

A microcapsule and magnetic technology, applied in the directions of microcapsule preparation, microsphere preparation, building components, etc., can solve the problems of limited pavement crack repair ability and limited utilization of capsules, and achieve good pavement repair effect and good application and promotion prospects. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

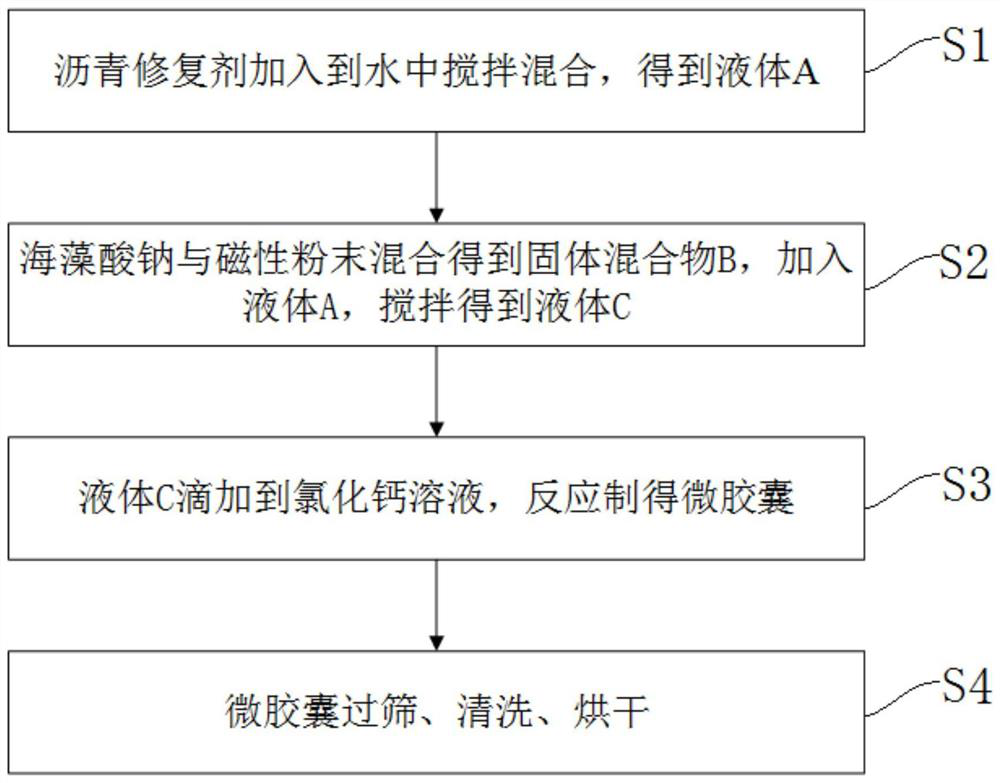

[0035] Another embodiment of the present invention discloses the preparation method of the above-mentioned controllable magnetic release microcapsules, combining figure 1 As shown, it includes the following steps:

[0036] S1: Add the asphalt repair agent into the water and stir to obtain liquid A.

[0037] S2: Weigh sodium alginate and mix with magnetic powder to obtain solid mixture B, add solid mixture B to liquid A, stir and mix to obtain liquid C.

[0038] S3: adding the liquid C dropwise into the calcium chloride solution, stirring and reacting to prepare microcapsules.

[0039] S4: Sieve, wash and dry the microcapsules prepared in step S3.

[0040] The preparation method of the controllable magnetic force release microcapsule is simple, the raw materials are controlled to ensure that there is an appropriate amount of magnetic powder in the microcapsule, and the specific material addition sequence makes the particle size distribution of the prepared microcapsule unifor...

Embodiment 1

[0049] Prepare the following materials: 100ml of sunflower oil, 500ml of water, 0.2g of NdFeB powder, 0.8g of sodium alginate, and 1.2g of calcium chloride dissolved in 60ml of water to prepare a 2%wt calcium chloride solution.

[0050] S1: Add sunflower oil to water, stir to mix, the stirring speed is 300r / min, and the stirring time is 1min, to obtain liquid A.

[0051] S2: Add the solid mixture B of sodium alginate and NdFeB powder into liquid A, stir and mix at a stirring speed of 300r / min for 10min to obtain liquid C.

[0052] S3: The calcium chloride solution is placed on an electromagnetic stirrer, liquid B is dropped into the calcium chloride solution by titration using a constant pressure separating funnel, and stirred for 1 hour to prepare microcapsules.

[0053] S4: Sieve the microcapsules, rinse with deionized water to ensure that the residual substances on the surface are cleaned, put them in an oven, dry at 80°C for 2 hours, take them out, and obtain controllable ...

Embodiment 2

[0055] Prepare the following materials: 100ml sunflower oil, 500ml water, 0.4g NdFeB powder, 0.8g sodium alginate, 1.2g calcium chloride dissolved in 60ml water to prepare a 2%wt calcium chloride solution.

[0056] S1: Add sunflower oil to water, stir to mix, the stirring speed is 300r / min, and the stirring time is 1min, to obtain liquid A.

[0057] S2: Add the solid mixture B of sodium alginate and NdFeB powder into liquid A, stir and mix at a stirring speed of 300r / min for 10min to obtain liquid C.

[0058] S3: The calcium chloride solution is placed on an electromagnetic stirrer, liquid B is dropped into the calcium chloride solution by titration using a constant pressure separating funnel, and stirred for 1 hour to prepare microcapsules.

[0059] S4: Sieve the microcapsules, rinse with deionized water to ensure that the residual substances on the surface are cleaned, put them in an oven, dry at 80°C for 2 hours, take them out, and obtain controllable magnetic release micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com