Composite fiber, preparation method of composite fiber and electronic component

A composite fiber and molecular chain technology, applied in the field of composite fiber and its preparation method and electronic components, can solve the problems of low thermal conductivity and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

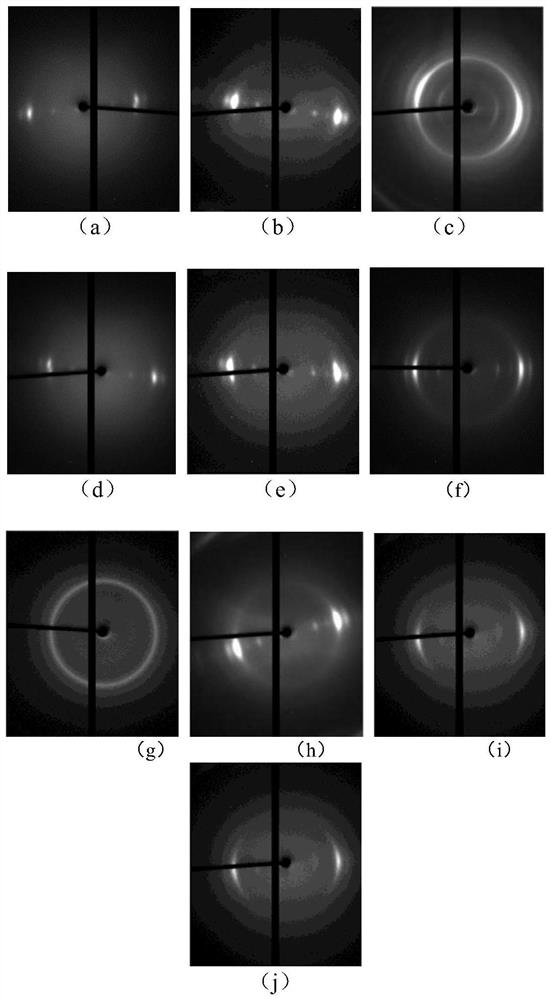

Image

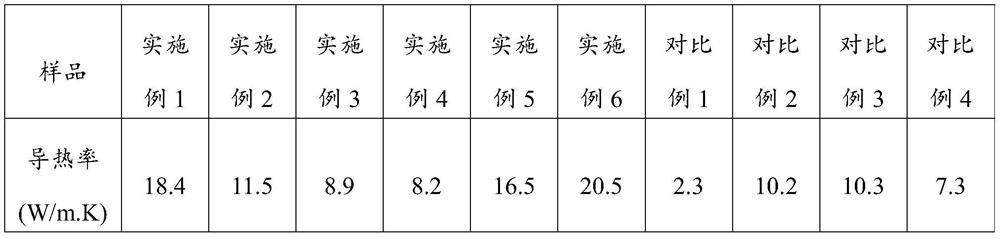

Examples

Embodiment 1

[0024] This embodiment has prepared a kind of composite fiber, and specific process comprises the following steps:

[0025] S1. Weigh 0.6g of carbon material modified dispersant TNWDIS at room temperature and add it to 100g of DMSO solution, stir with a magnetic stirrer for 20min to make TNWDIS evenly dispersed; add 2g of TNSM2 carbon nanotubes (CNTs), and stir with a magnetic stirrer , so that the carbon nanotubes are completely wetted by the solvent DMSO solution instead of floating on the water surface; then ultrasonic treatment for 5 minutes, the dispersion liquid is taken out and placed in ice water to cool, defoam, and then continue ultrasonication for a total of 30 minutes; after the ultrasonic , the dispersion liquid was centrifugally settled to remove undispersed agglomerated particles, the centrifugal speed was 2000r / min, and the centrifugal time was 30min; liquid, denoted as the first dispersion liquid A 1 . Dry the lower layer and precipitate to constant weight, ...

Embodiment 2

[0030] This embodiment has prepared a kind of composite fiber, and specific process comprises the following steps:

[0031]S1. Weigh 2g of TNSM2 carbon nanotubes (CNTs) at room temperature and add them to 100g of DMSO solution, stir with a magnetic stirrer to make the carbon nanotubes completely wetted by the DMSO solution; then ultrasonically treat for 5min, take out the dispersion and let it stand Cool in ice water, defoam, and then continue to sonicate for a total of 30min; Pass the upper liquid through a 300-mesh filter cloth to obtain the final dispersion of carbon nanotubes (CNTs), which is referred to as the first dispersion A 2 . Dry the lower layer and precipitate to constant weight, denoted as G 2 , the actual content of carbon nanotubes in the dispersion = 2-G 2 .

[0032] S2, at normal temperature, weigh 20g of PVA powder (model PVA-224, degree of alcoholysis 88%, degree of polymerization 2400), wash with deionized water, and then put it into an oven for drying...

Embodiment 3

[0036] This embodiment has prepared a kind of composite fiber, and specific process comprises the following steps:

[0037] S1. Weigh 0.6g carbon material modified dispersant TNWDIS at room temperature, add 58g dimethyl sulfoxide (DMSO) and 42mL deionized water blend solution, stir for 20min with a magnetic stirrer, so that TNWDIS is uniformly dispersed; add 2gTNSM2 Model carbon nanotubes (CNTs), use a magnetic stirrer to stir, so that the carbon nanotubes are completely wetted by the solvent DMSO / water blend solution, instead of floating on the water; then ultrasonic treatment for 5min, the dispersion is taken out and placed on ice Cool in water, defoam, and then continue ultrasonication for a total of 30 minutes; after the end of ultrasonication, centrifugally settle the dispersion to remove undispersed aggregated particles; The liquid passes through a 300-mesh filter cloth to obtain the final dispersion of carbon nanotubes (CNTs), which is referred to as the first dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com