Method for preparing fine niobium powder through calcium thermal reduction of niobium chloride in calcium chloride molten salt

A technology of calcium chloride molten salt and niobium chloride, applied in the field of calcithermal reduction of niobium chloride to prepare fine niobium powder, which can solve the problems of high energy consumption, low current efficiency, uneven particle size distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

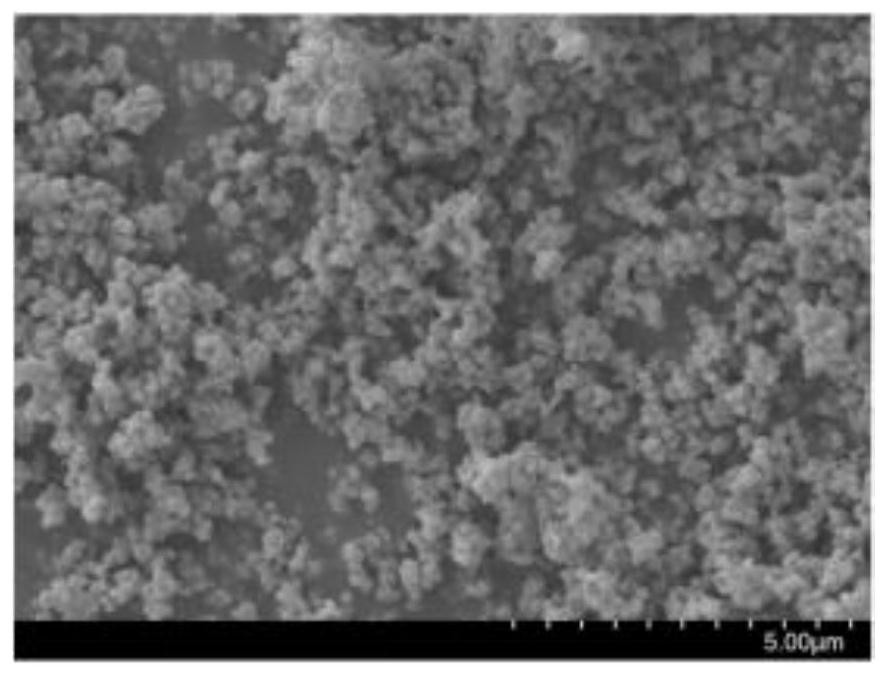

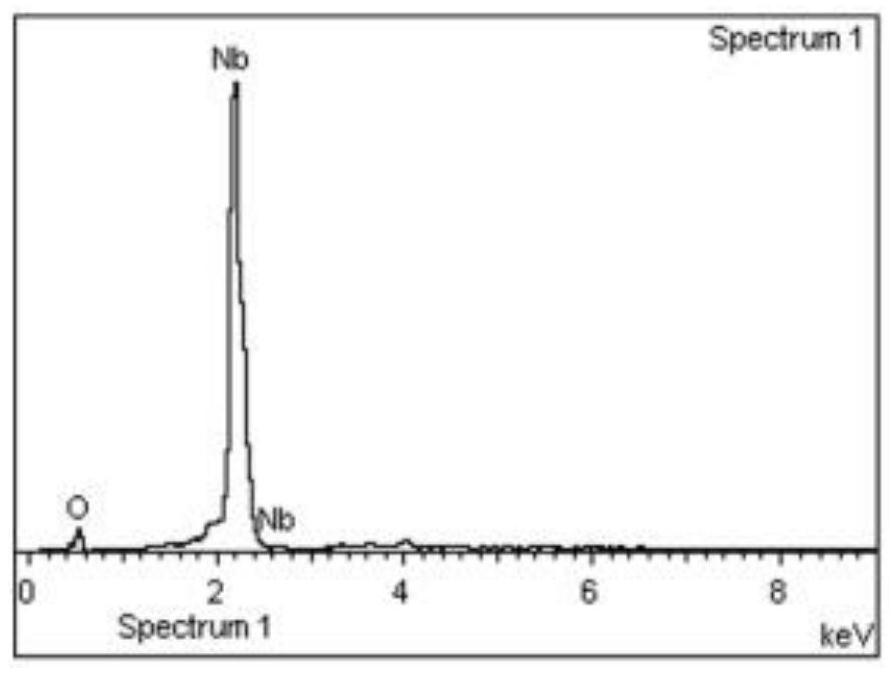

Image

Examples

Embodiment 1

[0023] A method for preparing fine niobium powder by calcithermal reduction of niobium chloride in calcium chloride molten salt, carried out according to the following steps:

[0024] S1. Vacuumize and dehydrate anhydrous calcium chloride in an atmosphere furnace. The vacuum dehydration temperature is 500° C., and the dehydration time is 12 hours; then add metallic calcium, and the mass ratio of added metallic calcium to anhydrous calcium chloride is 1. :50, raise the atmosphere furnace to the specified reaction temperature of 900°C and stir with argon gas to promote the dissolution of calcium metal in the molten calcium chloride salt. At the same time, the calcium metal in the molten calcium chloride salt is saturated before the calcium metal reacts. state;

[0025] S2, and then use argon gas to pass the evaporated niobium pentachloride gas into the calcium chloride molten salt that dissolves metallic calcium, so that a calcithermal reaction occurs to obtain a reduction produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com