Composite negative electrode material for lithium metal battery

A technology for lithium metal batteries and negative electrode materials, applied in battery electrodes, lithium batteries, nitrogen-metal/silicon/boron binary compounds, etc. Problems such as the energy density of the metal negative electrode and the inability to realize the interaction of lithium ions better

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

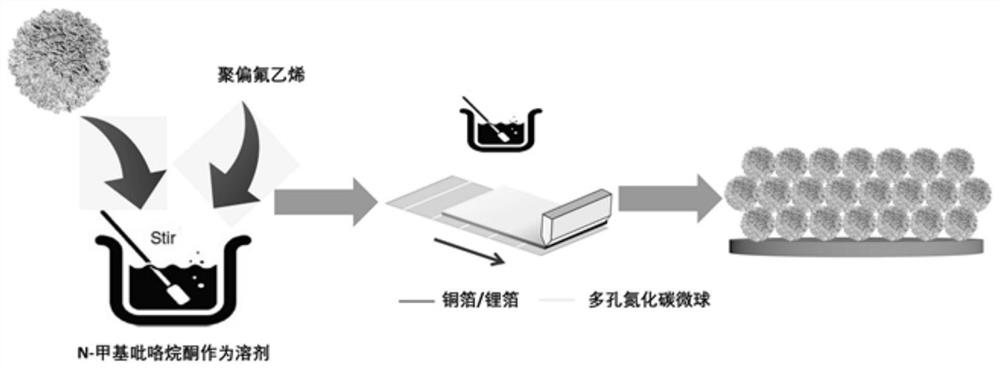

[0051] 1) 7.92mmol melamine was dissolved in 40mL dimethyl sulfoxide (DMSO) (Aladdin, Pur≥99.0%); 7.92mmol cyanuric acid (Aladdin, Pur≥99.0%) was dissolved in 20mL DMSO;

[0052] 2) The two solutions were heated to 60°C, stirred and mixed for about 15 minutes, and filtered;

[0053] 3) wash the filtrate several times with ethanol and deionized water respectively, and dry at 80°C;

[0054] 4) Dry the obtained white powder under argon at 550°C at 2°C min -1 The heating rate was calcined for 4 hours. In addition, a small amount of oxygen (0.1%-2%) was introduced during the calcining process, and finally, yellow porous carbon nitride microsphere powder was obtained;

[0055] 5) Mix the prepared porous carbon nitride microsphere powder with polyvinylidene fluoride (PVDF) in a 1-methyl-2-pyrrolidone (NMP) solvent at a mass ratio of 1:1, and stir for 10 hours to form a stable and uniform The massfraction of the total material is the slurry of 10wt%;

Embodiment 2

[0064] The preparation method is the same as in Example 1, the only difference being that the concentration of the slurry is 5%, a composite electrode is obtained, and the performance of the detection electrode is specifically as follows:

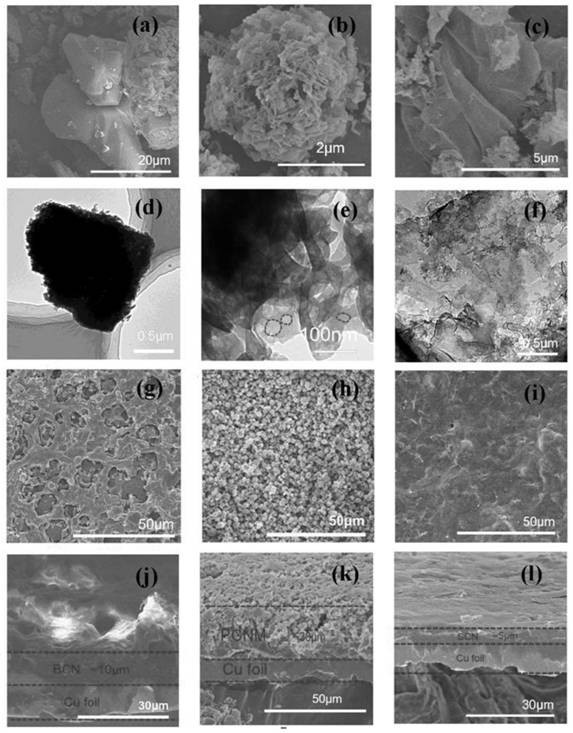

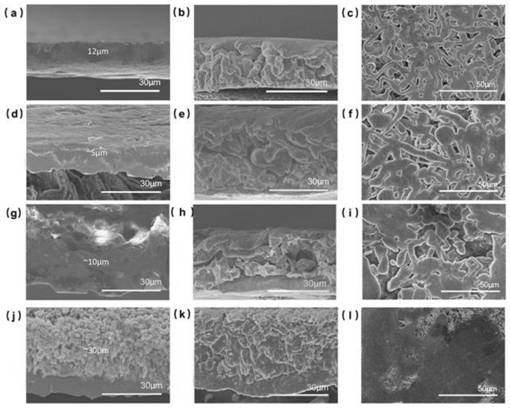

[0065] Image 6 It is the SEM photo of the composite electrode obtained by coating with different slurry concentrations, the left picture is the SEM photo of the 5% composite electrode, and the right picture is the SEM photo of the 10% composite electrode; Figure 7 The coulombic efficiency graph of the electrode obtained by coating under different slurry concentrations (PCNM+PVDF) in the lithium-copper half-cell test; Image 6 It can be seen that the slurry with a concentration of 5% is too diluted, the coated pole piece is very uneven, the surface presents a pitted structure, and there is obvious copper exposure, which is not conducive to the impact of carbon nitride microspheres on copper foil. / lithium foil for protection ( Image 6 ...

Embodiment 3

[0067] The preparation method is the same as that of Example 1, the only difference is that the thickness of the slurry is 100 μm, a composite electrode is obtained, and the performance of the electrode is tested, and the results are as follows:

[0068] As a result, it was found that the cross-section and surface of the electrode sheet obtained by the coating thickness of 100 μm were not smooth enough, and there was obvious copper exposure ( Figure 8 (a-b)); while the cross-section and surface of the electrode sheet obtained with a coating thickness of 200 μm are unconventional and uniform, and there is no obvious copper exposure ( Figure 8 (c-d)). from Figure 9 It can also be found that the coulombic efficiency of the electrode sheet with a coating thickness of 200 μm is better than that of the electrode sheet with a coating thickness of 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com