Copper-based current collector for inducing preferential transverse deposition of lithium metal negative electrode as well as preparation method and application of copper-based current collector

A lithium metal negative electrode and current collector technology, which is applied in the direction of negative electrodes, electrode carriers/current collectors, battery electrodes, etc., can solve the problems of induction or limitation of metal negative electrode deposition directions, and achieve easy scale-up and industrial application, with low equipment requirements , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a copper-based current collector that induces preferential lateral deposition of lithium metal negative electrodes, comprising the following steps:

[0053] S1. Clean the surface of copper-zinc-based foil: ultrasonically clean commercially available commercial brass foil three times with absolute ethanol, wipe the surface with dust-free paper, and then soak it in 0.1mol / L dilute hydrochloric acid for 30s to remove The oxide impurities on the surface of the foil are rinsed with deionized water and absolute ethanol and dried at room temperature for later use. The brass foil used is H62, the thickness is 20 μm, and the price is low.

[0054] S2. Precursor preparation by wet chemical method: Prepare an ammonia solution with a concentration of 0.03mol / L with deionized water and concentrated ammonia water, and then pre-cool at 2-8°C. After the solution temperature reaches the specified temperature, the copper after S1 treatment The zinc-based foil was e...

experiment example 1

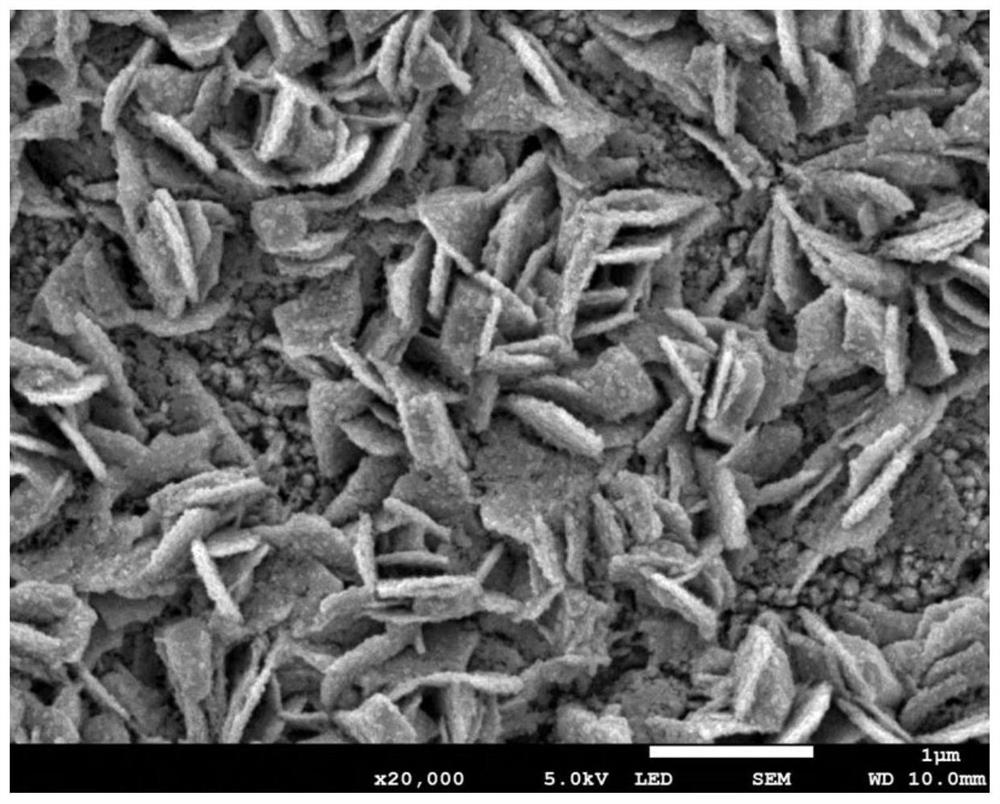

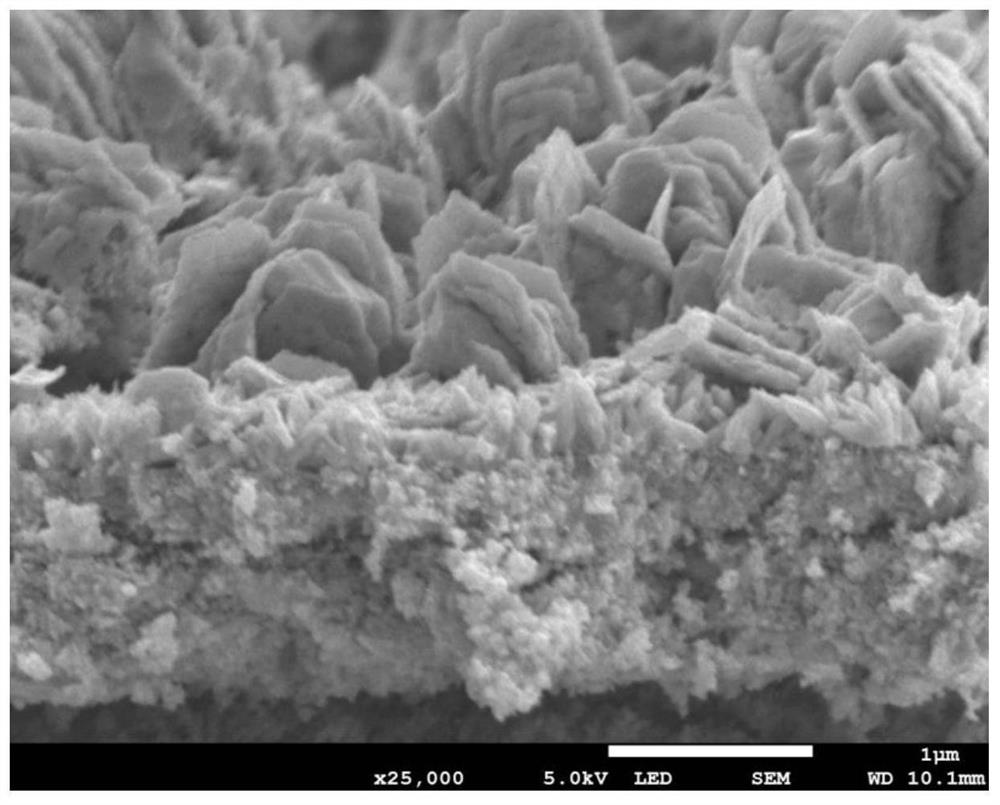

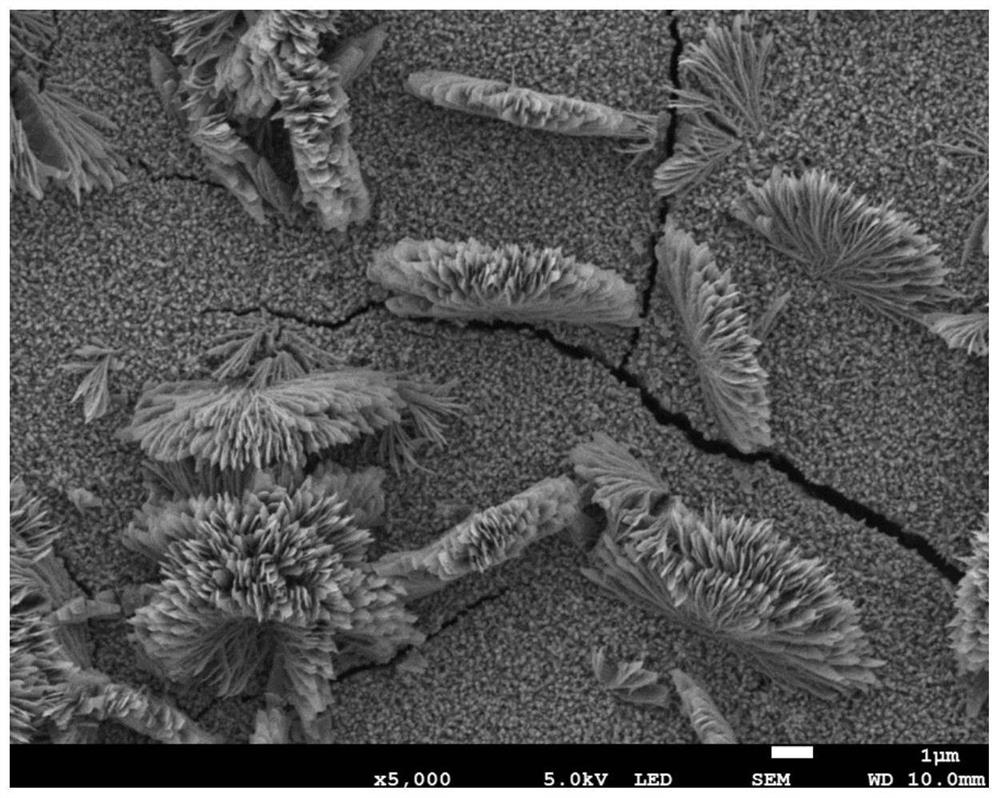

[0069] This experimental example compares the deposition morphology of lithium metal on a planar copper current collector and on a copper-based current collector that can induce its preferential lateral deposition.

[0070] Electrodeposition of lithium metal by assembling half-cells. In the half-cell, use commercial lithium foil as the negative electrode, 1MLiTFSI / DOL+DME (volume ratio 1:1)+1% LiNO 3 It is the electrolyte, PP is the diaphragm, and the current collector is the positive electrode. The assembly of the battery is carried out in a glove box protected by an argon atmosphere, and the oxygen value of water in the atmosphere is lower than 0.01ppm. The half-cells left for 24 hours were charged and discharged five times at a current density of 50 μA and a voltage range of 0 to 1 V for activation treatment, and then activated at 1 mA / cm 2 Electrodeposition was performed by discharging for two hours at a certain current density. The cells that completed the electrodepos...

experiment example 2

[0073] In this experimental example, the Coulombic efficiency of lithium metal deposition / dissolution was compared on a planar copper current collector and a copper-based current collector that can induce preferential lateral deposition of lithium metal.

[0074] This experimental example is tested in a half-cell, and the assembly method of the half-cell is the same as that of Experimental Example 1. The coulombic efficiency test was carried out by Xinwei 5V / 10mA battery tester. The deposition capacity is 1mAh / cm 2 , the stripping cut-off voltage is 1V. The current density of deposition and stripping is 1mA / cm 2 .

[0075] Figure 7 is the Coulombic efficiency curve of the half-cell obtained in Experimental Example 2.

[0076] Because on the copper-based current collector that can induce the preferential lateral deposition of lithium metal, the deposition of lithium metal is smoother, the formation of lithium dendrites is suppressed, and the generation of dead lithium is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com