Method for extracting cannabidiol from industrial cannabis sativa leaves

A technology for industrial hemp and cannabidiol, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as waste and inefficiency, increase extraction efficiency, improve extract yield, and achieve practical methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

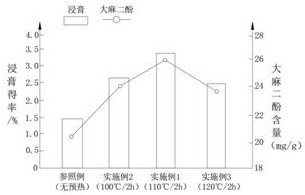

Embodiment 1

[0025] In an embodiment of the present invention, a method for extracting cannabidiol from industrial hemp leaves is characterized in that it comprises the following steps;

[0026] Step 1: Clean the industrial hemp leaves, dry them naturally, place them on a tray covered with aluminum foil, put them in an oven at 110°C for preheating for 2 hours, and cool them down for later use;

[0027] Step 2: Put the preheated industrial hemp leaves in a shaker, add an appropriate amount of enzyme solution to hydrolyze for 45 minutes, and obtain a hydrolyzate;

[0028] Step 3: Put the hydrolyzed solution in a blender, add 360ml of extraction solvent to stir and mix, and then perform rotary evaporation to remove the extraction solvent to obtain an oil;

[0029] Add anhydrous methanol to the oil, place it in a freezer at -37°C for 1 hour, and then centrifuge it in an environment at -5°C to obtain a supernatant;

[0030] Heating 10% activated carbon corresponding to the oil in the supernata...

Embodiment 2

[0041] Completely implement the scheme according to Example 1, the difference from Example 1 is: Step 1: Clean the industrial hemp leaves, dry them naturally, put them into a tray covered with aluminum foil, and put them in a 100°C oven for preheating. Treat for 2h, cool for later use.

Embodiment 3

[0043] Completely follow the scheme of Example 1, the difference from Example 1 and Example 2 is: Step 1: Clean the industrial hemp leaves, dry them naturally, put them in a tray covered with aluminum foil, and put them in a 120°C oven Preheating for 2 hours in the middle, cooling for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com