Preparation method of beta-nicotinamide mononucleotide

A single nucleotide, nicotinamide technology, applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of long production process, high organic impurity content, and high energy consumption, and achieves safety and reliability. The effect of improving environmental protection, reducing the content of organic impurities, and shortening the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

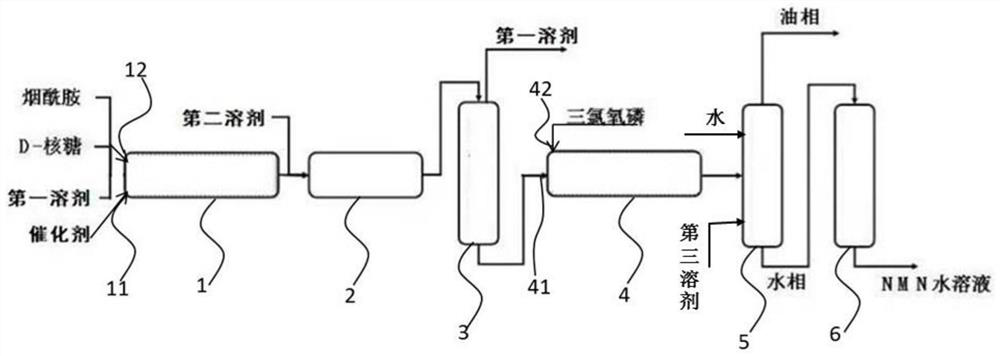

[0070] in such as figure 1 Carry out following reaction or separation step in the reaction system shown:

[0071] S1: Condensation reaction

[0072] Mix 38 parts of nicotinamide, 48 parts of D-ribose and 400 parts of tetrahydrofuran in the feeding tank, and add 70 parts of triethylsilicon trifluoromethanesulfonate into another feeding tank, and the liquids in the two feeding tanks are respectively from The first feed port 12 and the second feed port 11 are driven into the first microchannel reactor 1, and the temperature of the first nine microchannel modules of the first microchannel reactor 1 is set to be 80° C., and the tenth microchannel The module temperature is 75°C, the total residence time is set to 2 minutes, and the material A is obtained through condensation reaction.

[0073] S2: thin film evaporator evaporation

[0074] Material A and triethyl phosphate are mixed in the mixer 2 at a mass ratio of 5:3, and then poured into the thin film evaporator 3 continuously...

Embodiment 2

[0080] S1: Condensation reaction

[0081] Mix 38 parts of nicotinamide, 48 parts of D-ribose and 500 parts of tetrahydrofuran in the feeding tank, and add 70 parts of triethylsilicon trifluoromethanesulfonate into another feeding tank, and the liquids in the two feeding tanks are respectively from The first feed port 12 and the second feed port 11 are driven into the first microchannel reactor 1, and the temperature of the first nine microchannel modules of the first microchannel reactor 1 is set to be 75° C., and the tenth microchannel The module temperature is 70°C, the total residence time is set to 4 minutes, and the material A is obtained through condensation reaction.

[0082] S2: thin film evaporator evaporation

[0083] Material A and triethyl phosphate were mixed in the mixer 2 at a mass ratio of 5:4 and then poured into the thin-film evaporator 3 continuously. Other steps were the same as S2 in Example 1.

[0084] Both S3 and S4 are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com