IGCC combined heat and power generation system and method with high heat and power ratio

A combined heat and power generation and high heat technology, applied in the direction of charging system, turbine/propellant fuel delivery system, combined combustion mitigation, etc., can solve the problems of limited central heating and cooling functions, limited steam volume, low heat-to-electricity ratio, etc. Achieve the effect of reducing heating cost, lowering construction cost and high heat quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

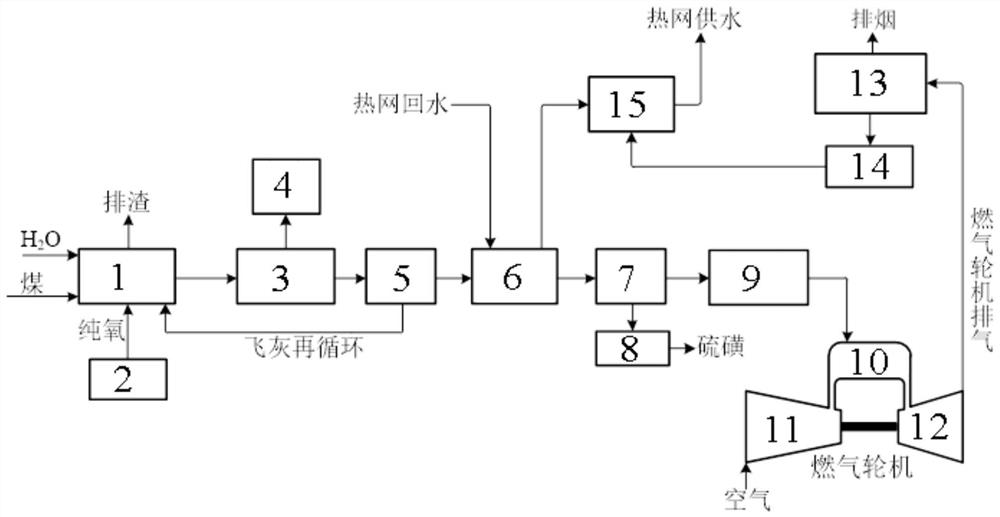

[0029] Such as figure 1 As shown, the IGCC cogeneration system with high heat-to-electricity ratio described in this application includes a gasifier 1, a chilling unit 3, a dust removal unit 5, a waste heat recovery unit 6, a desulfurization unit 7, a syngas modulation unit 9, Combustion chamber 10, turbine 12, waste heat boiler 13, steam turbine 14 and peak heater 15.

[0030] The gasifier 1 is connected with water vapor and coal, and the gasifier 1 is connected with a cryogenic air separation system 2, and the cryogenic air separation system 2 is used to input pure oxygen into the gasifier 1.

[0031] The chilling unit 3 is connected to the gray water treatment unit 4. The crude syngas is quenched and cooled by water in the chilling unit 3, and gray water is generated at the same time, which is sent to the gray water treatment unit 4 to treat the gray water to avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com