Readily adherable polyester film

A polyester film, easy-adhesive technology, applied in the direction of polyester coatings, film/sheet adhesives, adhesives, etc., can solve the high toxicity of organotin, the limitation of organotin compounds, and light-curable adhesives Eliminates problems such as reduced adhesion with the easy-adhesive layer, and achieves excellent adhesion and environmental suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0199] (1) Adjustment of coating liquid

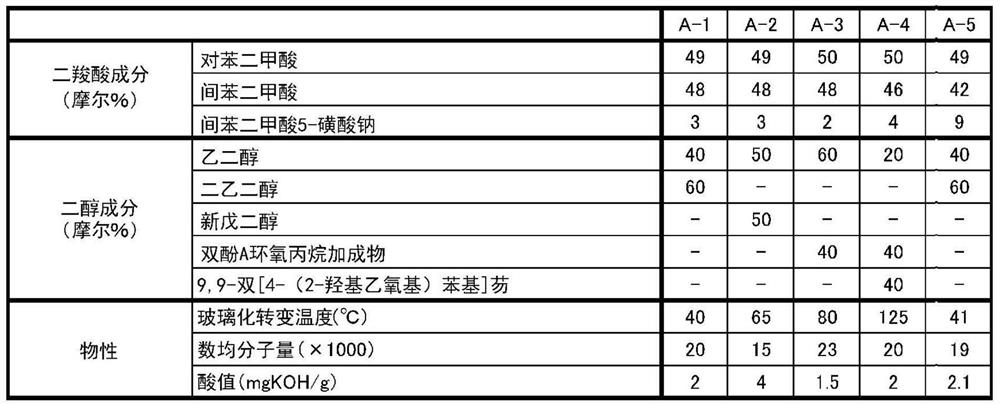

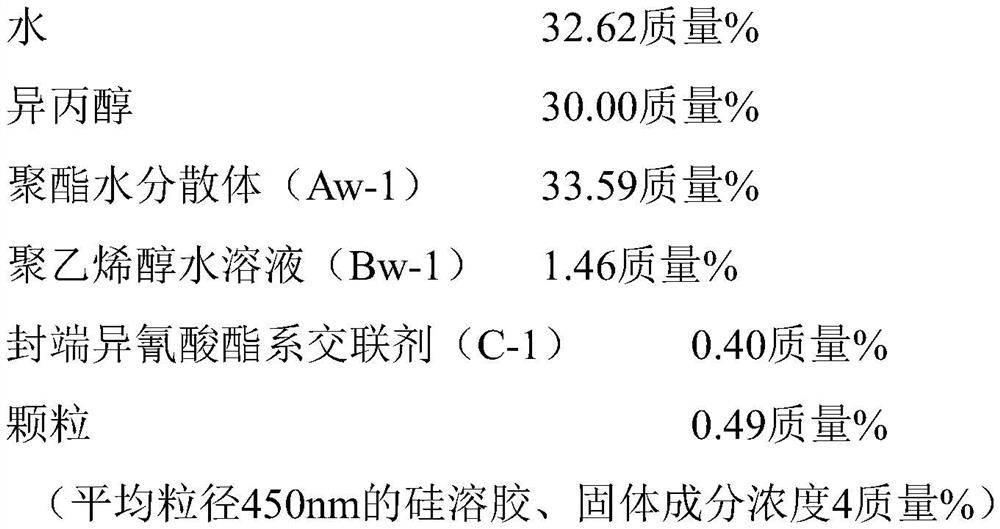

[0200] Mix the following coating agents to prepare the solid content ratio of polyester resin (A-1) / polyvinyl alcohol resin (B-1) / reactive methylene-blocked isocyanate crosslinking agent (C-1) It became a coating liquid of 92 / 3 / 5. The aqueous polyester dispersion uses the aqueous dispersion (Aw-1) that is dispersed with the polyester resin of acid value 2KOHmg / g, and the polyvinyl alcohol aqueous solution uses the aqueous solution that is dissolved in the polyvinyl alcohol (Bw- 1).

[0201]

[0202]

[0203] (2) Manufacture of easy-adhesive polyester film

[0204] As a film base polymer, PET resin pellets having an intrinsic viscosity (solvent: phenol / tetrachloroethane = 60 / 40) of 0.62 dl / g and substantially no particles were dried at 135°C under a reduced pressure of 133 Pa. 6 hours. Then, it was supplied to an extruder, melt-extruded into a sheet form at about 280° C., and quenched and solidified on a rotating cooling metal...

Embodiment 2

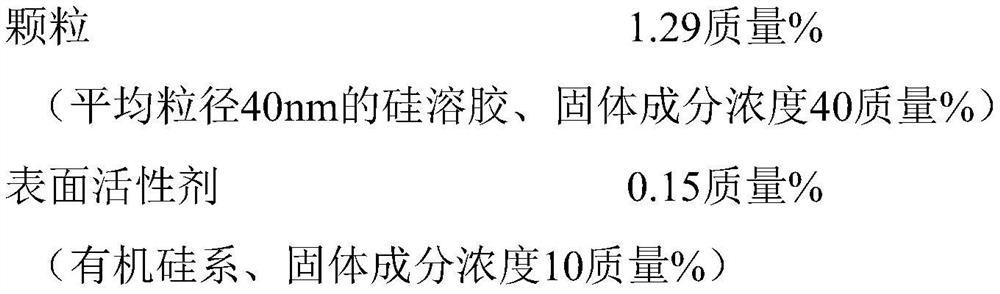

[0208] The following coating agents were mixed, and the solid content ratio of polyester resin (A-1) / polyvinyl alcohol resin (B-1) / active methylene blocked isocyanate crosslinking agent (C-1) Except having changed into 83 / 5 / 12, it carried out similarly to Example 1, and obtained the easily-adhesive polyester film.

[0209]

[0210]

Embodiment 3

[0212] In the coating solution, except that the polyester-based resin was changed to (A-2) and the polyester aqueous dispersion was changed to (Aw-2), the same procedure as in Example 2 was carried out to obtain an easily-adhesive polyester film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com