Production process of thick wire diameter titanium alloy wire

A titanium alloy wire and production process technology, applied in metal rolling and other directions, can solve the problems of large tolerance span of titanium alloy wire, expensive processing scraps, and burn workers caused by wire, so as to achieve uniform force and sufficient lubrication, Adhesion is not easy to fall off, reducing the effect of pulling cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

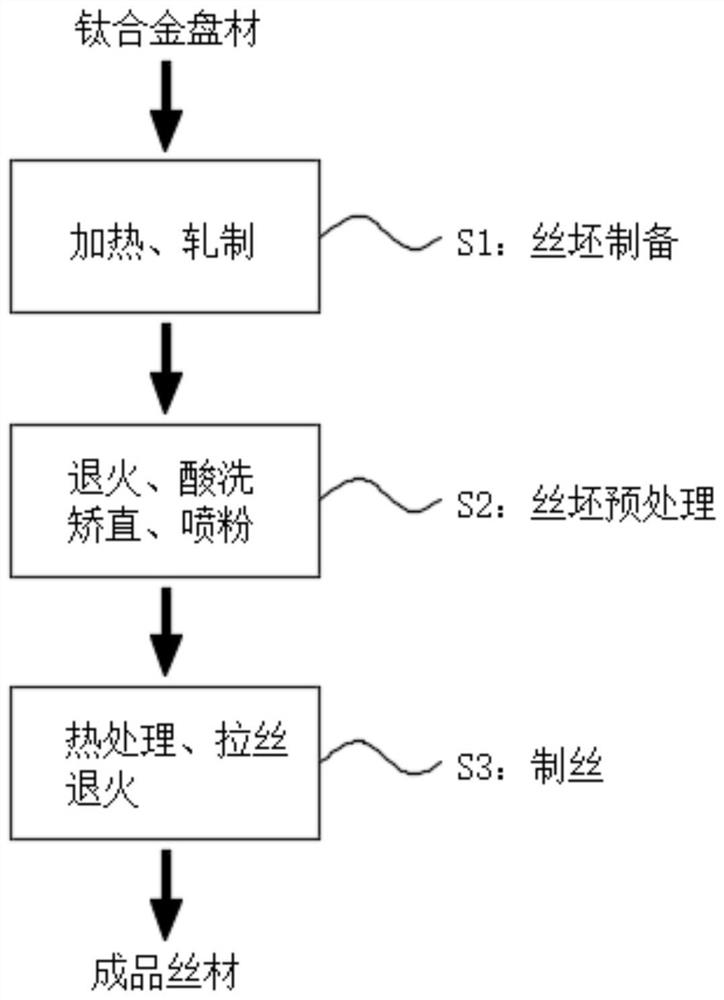

[0037] see figure 1 As shown, the present embodiment prepares the titanium alloy wire blank, and the specific process is as follows:

[0038] Take a group of TC4 titanium alloy discs and add them to the heating furnace, raise the temperature to 950°C in an argon atmosphere, and keep warm for 10 minutes. Using a four-roller continuous rolling mill, four passes are used for rolling, and the total deformation is 65%. The discs are rolled Made of φ14 titanium alloy wire;

[0039] Then take a group of TC4 titanium alloy discs and put them into the heating furnace, raise the temperature to 1000°C in an argon atmosphere, and keep it warm for 8 minutes. Using a four-roller continuous rolling mill, six-pass rolling, the total deformation is 82%, and the discs are Rolled into φ10 titanium alloy wire.

Embodiment 2

[0041] see figure 1 As shown, the present embodiment pretreats the titanium alloy wire blank prepared in Example 1, and the specific process is as follows:

[0042] annealing:

[0043] Take the φ14 titanium alloy wire and put it into the heating furnace, raise the temperature to 780°C and keep it for 50 minutes, then take it out of the furnace and air cool it to 120°C to complete the annealing treatment of the φ14 titanium alloy wire;

[0044] Take the φ10 titanium alloy wire and put it into the heating furnace, raise the temperature to 750°C and keep it for 70 minutes, then take it out of the furnace and air cool it to 120°C to complete the annealing treatment of the φ10 titanium alloy wire;

[0045] Pickling:

[0046] Add φ14 titanium alloy wire into dilute sulfuric acid solution with a volume fraction of 7%, scrub with a wire brush for 25 minutes, rinse with tap water and dry with hot air;

[0047]Add the φ10 titanium alloy wire into a dilute sulfuric acid solution with ...

Embodiment 3

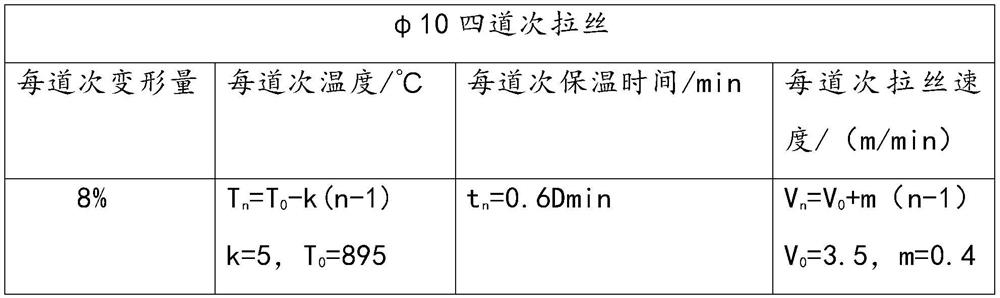

[0051] see figure 1 As shown, in this embodiment, the wire blank of φ10 is drawn for four passes, and the specific process is as follows:

[0052] Heat treatment: import the pretreated silk billet into the heating furnace, heat and keep it warm under the protection of argon gas;

[0053] Multi-pass wire drawing: Pass one end of the heat-treated wire billet through the drawing die and pull it through the tractor, then repeat the heat treatment and drawing until the designed wire diameter is reached, the winding machine coils the wire, and each coil is demolded Front stop, the self-locking device clamps the wire and cuts off from the end of the wire;

[0054] The specific parameters are shown in Table 1:

[0055] Table 1

[0056]

[0057] Finished product annealing: Put the closed wire into a heating furnace, raise the temperature to 680°C, keep it warm for 2 hours, and then air cool to room temperature to make titanium alloy wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com